Porous biological support slurry, three-dimensional porous biological support and preparation method of support

A bio-scaffold, three-dimensional porous technology, applied in the field of medical materials, can solve the problems that porous bio-scaffold materials cannot be effectively extruded, cannot maintain line shape and span, and is time-consuming and labor-intensive in molding, and achieves flexible shape and size. , complete structure, good connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In yet another aspect of the embodiments of the present invention, the embodiments of the present invention also provide a method for preparing the above-mentioned three-dimensional porous bioscaffold. In one embodiment, the preparation method of the three-dimensional porous bioscaffold comprises the following steps:

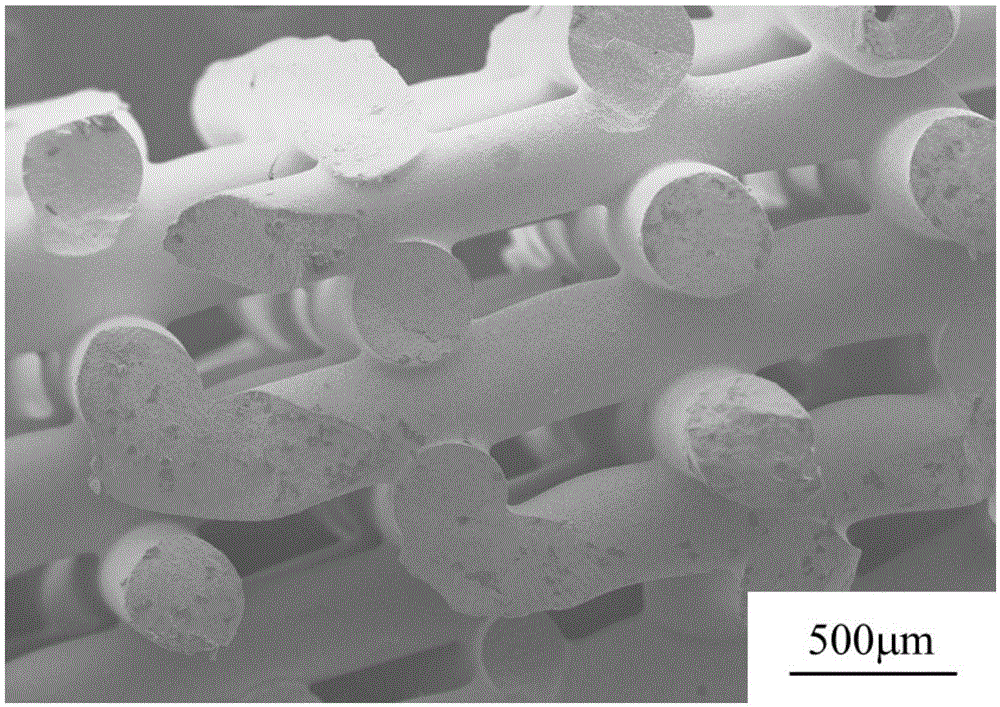

[0035] Step S01: Convert the three-dimensional porous bioscaffold design drawing into a code language recognizable by the computer, and write the slurry of the porous bioscaffold in the embodiment of the present invention described above along the path specified by the computer according to the code language Forming technology extrudes layer by layer to form a green body with multi-layer ordered three-dimensional porous network structure;

[0036] Step S02: The green body is dried and sintered to remove organic components in the green body.

[0037] Specifically, in the above step S01, the three-dimensional porous bioscaffold design is one of the bases o...

Embodiment 1

[0047] This embodiment is a porous bioscaffold slurry for direct writing. The porous biological support slurry (ceramic slurry) includes a mixture of hydroxyapatite powder and zirconia powder, ammonium citrate dispersant and PVA binder, and the content of hydroxyapatite powder is 1% of the mixed powder. 50%wt, the particle size of hydroxyapatite powder is about 40-100nm, and the particle size of zirconia powder is about 100-200nm; the content of the ammonium citrate dispersant in the porous biological support slurry is 0.5%wt , the content of the PVA binder in the porous biological scaffold slurry is 0.5%wt.

[0048] The solid phase content of the bioceramic scaffold slurry is 55%wt, and the solvent of the slurry is deionized water.

[0049] In Example 1, before the preparation of the porous bioscaffold slurry, the mixture of hydroxyapatite powder and zirconia powder was ball milled with alcohol as a grinding aid, placed in a constant temperature drying oven after 24 hours, a...

Embodiment 2

[0051] This embodiment is a porous bioscaffold slurry (ceramic slurry) for direct writing. The ceramic slurry includes a mixture of hydroxyapatite powder and zirconia powder, a methylcellulose dispersant and a PVB binder; the content of the hydroxyapatite powder is 60% of the mixed powder, and the hydroxyapatite The particle size of the powder is about 100-150nm, and the particle size of the zirconia powder is about 200-300nm; the content of the methylcellulose dispersant is 1%wt, and the content of the PVB binder is 1%wt.

[0052] The solid content of the bioceramic scaffold slurry is 65%wt

[0053] The solvent of the slurry is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com