Fluid catalytic cracking catalyst containing aluminum sol binder, and preparation method thereof

A technology of cracking catalyst and aluminum sol, which is applied in the direction of catalytic cracking, physical/chemical process catalyst, molecular sieve catalyst, etc., and can solve the problem of low activity of cracking catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

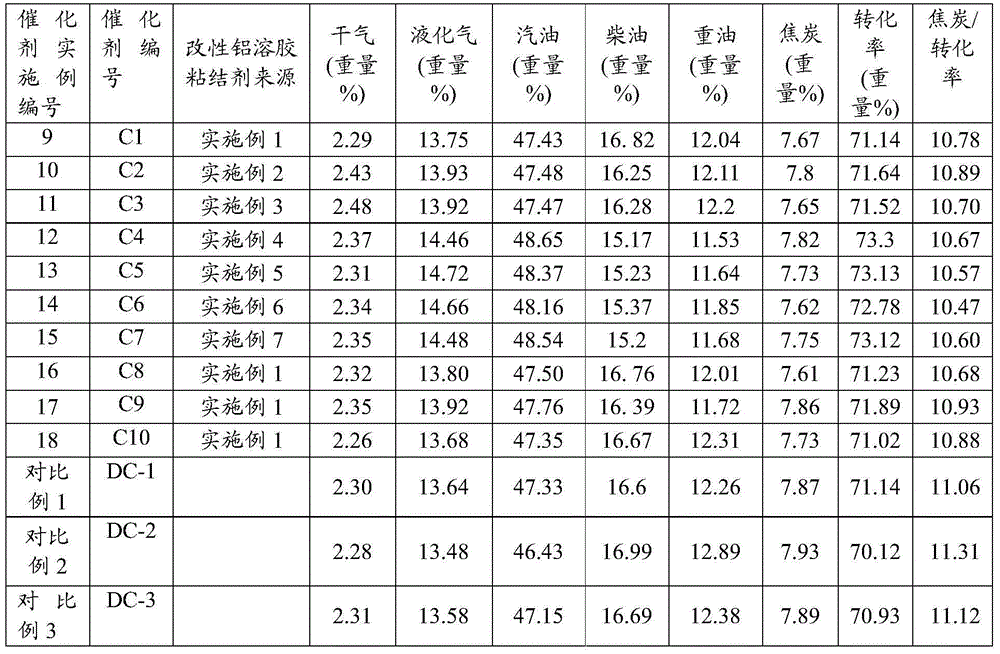

Examples

preparation example Construction

[0053] The preparation method of catalytic cracking catalyst provided by the invention preferably comprises the following steps:

[0054] (1) Contact NaY molecular sieve with rare earth solution or the mixed solution of rare earth solution and ammonium salt, after filtering, washing and drying, perform the first roasting treatment to obtain rare earth sodium Y molecular sieve; then beat rare earth sodium Y molecular sieve And contact with ammonium salt solution or acid solution, filter and mix with rare earth solution, adjust the pH value of the slurry to 6-10, filter or not filter, dry, and perform the second roasting treatment to obtain the rare earth Y of the present invention type molecular sieve.

[0055] In the above preparation process, the silicon-aluminum atomic ratio of the raw material NaY molecular sieve is preferably greater than 2.5 and the crystallinity is greater than 80%. In the process of contacting the NaY molecular sieve with the rare earth solution or the...

Embodiment approach

[0063] According to the preparation method of the catalytic cracking catalyst provided by the present invention, the preparation method of the modified aluminum sol, the first specific embodiment, comprises the following steps:

[0064](1) Add the metal aluminum source, the silicon source of the soluble silicon-containing compound, and water into the reactor, wherein the temperature of the mixture obtained in the reactor is not lower than 60°C, for example, 60-102°C. Heating, or reach described temperature by mixing the higher raw material of temperature; The consumption of water makes in the reactor by the silicon element that soluble silicon-containing compound introduces and water (comprising the water that adds and the water that soluble silicon-containing compound silicon source introduces ) in a weight ratio of 0.1-10:100, such as 1-10:100 or 0.1-5:100 or 0.05-1.5:100 or 0.1-1.4:100 or 0.15-1.3:100; metal in terms of Al The weight ratio of the aluminum source to the solu...

Embodiment 1

[0086] 280 grams of aluminum chips (calculated as Al), 1055 grams of deionized water, and 115 grams of water glass aqueous solution (containing Si9.33% by weight, Na4.63% by weight) were put into a three-necked flask and heated to 60°C. Slowly add 678 ml of 1:1 chemically pure hydrochloric acid into the three-necked flask, and the addition time of hydrochloric acid is 3 hours; then control the reaction temperature at, for example, 90-95°C, and react for 19 hours; cool the product to 60-70°C, and filter. Residual aluminum shavings from the reaction were weighed to be 29 grams, i.e. an excess of 11.6% aluminum, and the product was analyzed as follows: Al content 12.20% by weight, Cl content 6.5% by weight, Si content 0.52% by weight, Al / Cl (weight ratio) 1.88: 1. Al / Si (weight ratio) 23.5:1, pH 4.0. The obtained modified aluminum sol is designated as SA-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com