Method for treating ballast water by using singlet oxygen

A singlet oxygen and ballast water technology, which is applied in the direction of oxidized water/sewage treatment, can solve the problems of ultraviolet disinfection limited by light source and low heat treatment efficiency, and achieve the effect of strong reactivity, moderate price and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific Embodiment 1: This embodiment is a method for treating ballast water with singlet oxygen, which is realized through the following steps: adding the catalyst and the oxidant to the ballast water in a molar ratio of 1:(1-10) , control the concentration of the oxidizing agent in the ballast water to 20-1000mg / L, the reaction time is 30-120min, and the water is kept in a stirring state during the treatment process, that is, the treatment of the ballast water with singlet oxygen is completed; wherein the catalyst is acetone acid; the oxidizing agent is a peroxide.

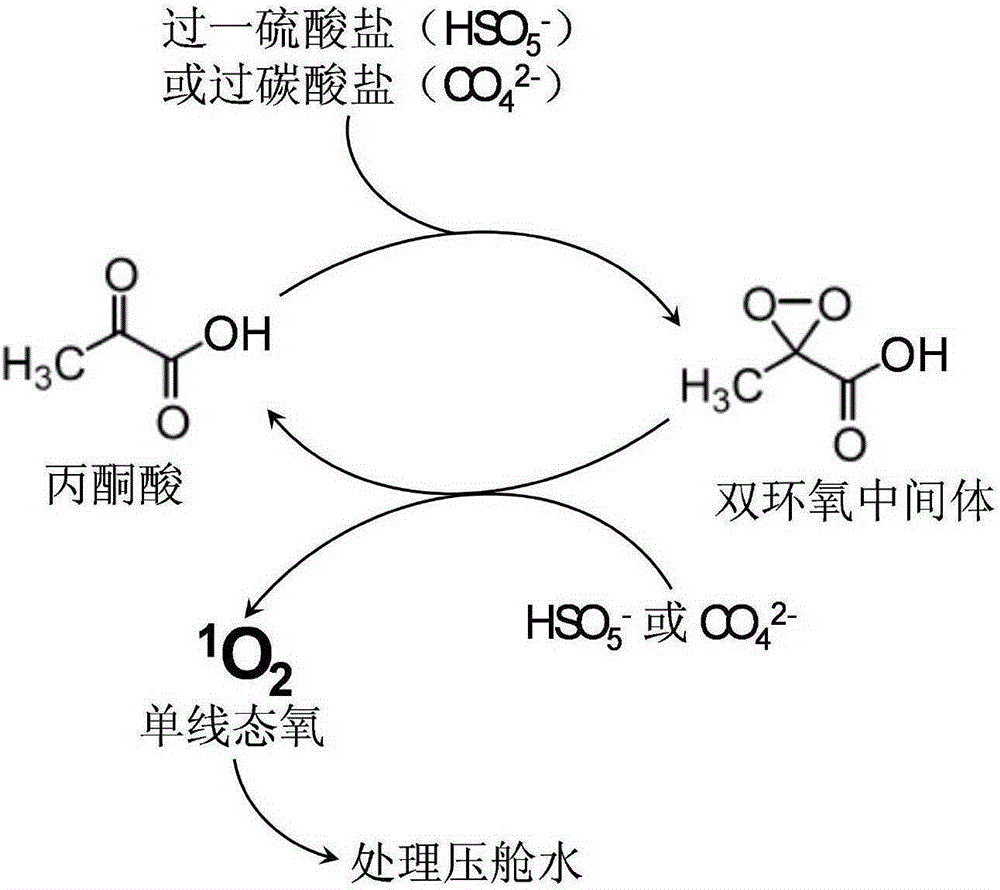

[0018] The principle of a method for removing algae using singlet oxygen in this embodiment is as follows: first, pyruvic acid catalyzes peroxide (peroxymonosulfate, percarbonate) to produce a diepoxy intermediate; then, the diepoxide intermediate The body further reacts with peroxide to produce singlet oxygen ( 1 o 2 ) and pyruvic acid, while the diepoxy intermediates also self-decompose to produce si...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the peroxide is a mixture of one or more of persulfate and percarbonate in any ratio. Others are the same as in the first embodiment.

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the persulfate is sodium persulfate (NaHSO 5 ), potassium persulfate (KHSO 5 ), ammonium persulfate (NH 4 HSO 5 ), calcium persulfate (Ca(HSO 5 ) 2 ), magnesium persulfate (Mg(HSO 5 ) 2 ) in one or several mixtures in any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is different from specific embodiment one: percarbonate is sodium percarbonate (Na 2 CO 4 ), potassium percarbonate (K 2 CO 4 ) in one or two mixtures in any ratio. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com