Multi-variety compound fertilizer and biomass granular fertilizer production method thereof

A technology of biomass particles and production methods, which can be applied to fertilizer mixtures, fertilization devices, agricultural gas emission reduction, etc., can solve problems such as heavy workload, and achieve the effects of saving man-hours, reducing man-hours of fertilization, and reducing non-point source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

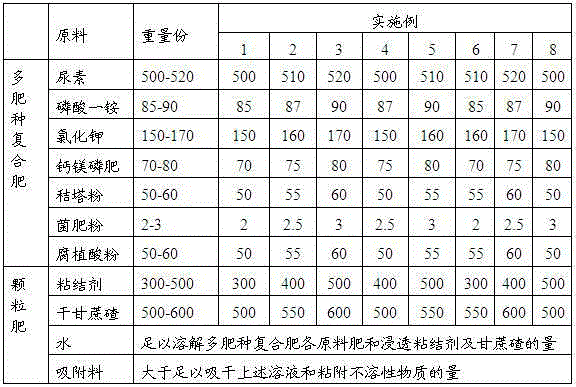

[0016] Example 1 (contrast the raw materials and weight proportioning value of Example 1 in the above table):

[0017] After mixing 500 parts of urea, 85 parts of monoammonium phosphate, 150 parts of potassium chloride, 70 parts of calcium magnesium phosphate fertilizer, 50 parts of straw tower powder, 2 parts of multi-functional EM powder or agricultural crown brand bacterial fertilizer powder, and 50 parts of humic acid powder Mix well to get this multi-fertilizer compound fertilizer, mix it with water at a ratio of 1: (100-150), and spray it on the leaves or roots of crops to fertilize. If it is made into granular fertilizer, add 300 parts of cornstarch or potato starch as a binder after mixing well, crush (or cut) 500 parts of dry sugarcane ballast with a particle size of 2-4mm, and add enough Dissolve the multi-fertilizer compound fertilizer and the amount of water soaked into the binder and sugarcane ballast, stir at a medium speed for 1 hour, and after fully mixing, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com