Mono-ammonium glycyrrhizinate and preparing method thereof

A technology of glycyrrhizic acid monoammonium salt and glycyrrhizic acid precipitant, applied in the field of glycyrrhizic acid monoammonium salt and preparation thereof, can solve the problems of high production cost and high impurity content of glycyrrhizic acid monoammonium salt, achieve good quality and reduce production cost , the effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

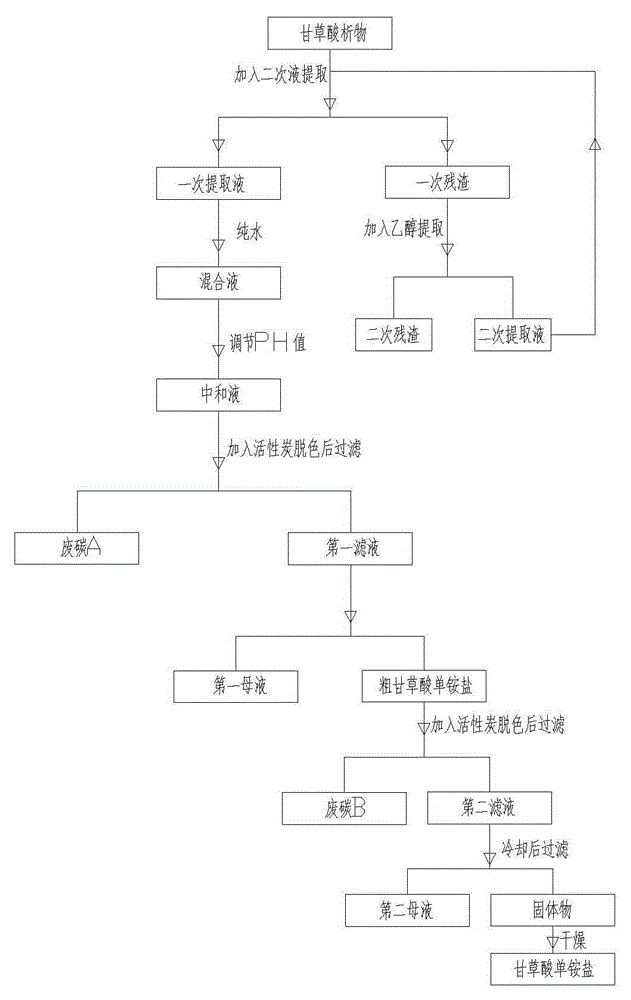

[0019] Example 1, such as figure 1 As shown, the glycyrrhizic acid monoammonium salt is obtained according to the following preparation method: in the first step, the glycyrrhizic acid precipitate is weighed by 200kg to 500kg, and the glycyrrhizic acid precipitate is added to the weighed glycyrrhizic acid precipitate 8 times to 12 times. Double the mass of the secondary extract and mix evenly, extract at a temperature of 30°C to 60°C for 1h to 4h, stand still for 4h to 8h after extraction, and obtain the primary extract and primary residue after filtration; the second step, in the primary Add pure water to the extract and mix evenly to obtain a mixed solution. After the pure water is added, the mass percentage of water in the mixed solution is 10% to 15%, and then the pH value of the mixed solution is adjusted to 4 to 5 to obtain a neutralized solution. The third step is to add 10kg to 100kg of activated carbon to the neutralizing solution, stir and decolorize at a temperat...

Embodiment 2

[0020] Example 2, such as figure 1 As shown, the glycyrrhizic acid monoammonium salt is obtained by the following preparation method: the first step, weigh the glycyrrhizic acid precipitate by 200kg or 500kg, add the glycyrrhizic acid precipitate 8 times or 12 twice the mass of the secondary extract and mix evenly, extract at a temperature of 30°C or 60°C for 1h or 4h, stand still for 4h to 8h after extraction, and obtain the primary extract and primary residue after filtration; the second step, in the primary Add pure water to the extract and mix evenly to obtain a mixed solution. After the pure water is added, the mass percentage of water in the mixed solution is 10% or 15%, and then the pH value of the mixed solution is adjusted to 4 or 5 to obtain a neutralized solution. ; The third step is to add 10kg or 100kg of activated carbon to the neutralizing solution, stir and decolorize at a temperature of 65°C or 75°C for 30min or 60min, and filter while it is hot to obtain w...

Embodiment 3

[0021] Embodiment 3, as the optimization of above-mentioned embodiment, secondary extracting solution obtains by following method when starting up: add the ethanol aqueous solution of 8 times to 12 times of quality of glycyrrhizic acid precipitation in glycyrrhizic acid precipitation, extraction temperature is 30 ℃ to 60 ℃, the extraction time is 1h to 4h, after extraction, let it stand for 4h to 8h, and obtain the primary filtrate and the primary residue after filtration, add the ethanol aqueous solution with 8 times to 12 times the mass of the primary residue to the primary residue, at a temperature of Extract at 30°C to 60°C for 1h to 4h, stand still for 4h to 8h after extraction, and obtain the secondary extract after filtering. The secondary extraction solution is used as the solvent for the next extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com