Polyacrylic woodware emulsion with core-shell bi-crosslinking structure and preparation method thereof

A technology of polyacrylic woodware and double cross-linking, which is applied in the direction of coating, etc., can solve the problem of low film-forming temperature, and achieve the effect of low film-forming temperature, high hardness and high degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

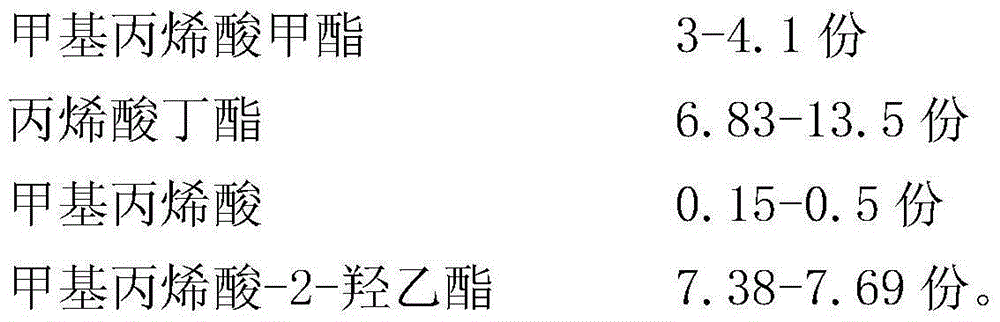

[0034] Polyacrylic acid woodware emulsion with core-shell double cross-linked structure, prepared from the following components according to the following parts by weight:

[0035]

[0036] The preparation method of polyacrylic acid woodware emulsion with core-shell double crosslinking structure has the following steps:

[0037] (1) Preparation of pre-emulsion

[0038] At room temperature, add 16.31 parts of core layer monomer, 0.16 parts of emulsifier, 0.04 parts of initiator and 8 parts of deionized water into reactor A, stir at a stirring speed of 1000rmp for 15min to obtain a core layer Pre-emulsion; in the same way, all the shell monomers and 0.06 parts of emulsifier are added to reactor B equipped with 9 parts by mass of deionized water, and the stirring speed is 1000rmp, stirring for 15min to obtain the shell monomer pre-emulsion.

[0039] (2) Preparation of seed emulsion

[0040] At room temperature, in a four-necked flask equipped with a condenser tube, a thermo...

Embodiment example 2

[0047] Polyacrylic acid woodware emulsion with core-shell double cross-linked structure, prepared from the following components according to the following parts by weight:

[0048]

[0049]

[0050]The preparation method of polyacrylic acid woodware emulsion with core-shell double crosslinking structure has the following steps:

[0051] (1) Preparation of pre-emulsion

[0052] At room temperature, disperse 13.67 parts of the core layer monomer, 0.29 parts of the emulsifier, 0.08 parts of the initiator, and 8 parts of the deionized high-speed dispersion for 20 minutes to obtain the core layer pre-emulsion; similarly, all the shell layer monomers 1. Add 0.15 parts of emulsifier into 8 parts of deionized water, and disperse at high speed for 20 minutes to obtain a shell monomer pre-emulsion.

[0053] (2) Preparation of seed emulsion

[0054] At room temperature, in a four-necked flask equipped with a condenser, a thermometer, a stirring paddle and a constant pressure drop...

Embodiment example 3

[0061] Polyacrylic acid woodware emulsion with core-shell double cross-linked structure, prepared from the following components according to the following parts by weight:

[0062]

[0063] The preparation method of polyacrylic acid woodware emulsion with core-shell double crosslinking structure has the following steps:

[0064] (1) Preparation of pre-emulsion

[0065] At room temperature, 17.40 parts of the core layer monomer, 0.20 parts of the emulsifier, 0.04 parts of the initiator, 8.5 parts by mass of deionized high-speed dispersion 18min to obtain the core layer pre-emulsion; Add 0.15 parts of emulsifier to 8.5 parts by mass of deionized water, and disperse at high speed for 30 minutes to obtain a shell monomer pre-emulsion.

[0066] (2) Preparation of seed emulsion

[0067] At room temperature, in a four-necked flask equipped with a condenser, a thermometer, a stirring paddle and a constant pressure dropping funnel, drop into 0.01 parts of initiator, 0.23 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com