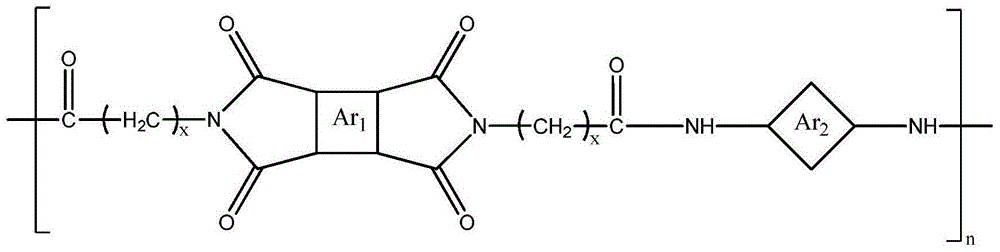

Liquid-crystal polyamide imide and preparation method therefor

A polyamide-imide and imide diacid technology, applied in the field of polymer compound preparation, can solve the problems of high imidization temperature, high dielectric constant, high moisture absorption rate, etc., and achieve less reaction by-products and high heat Effect of high decomposition temperature and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

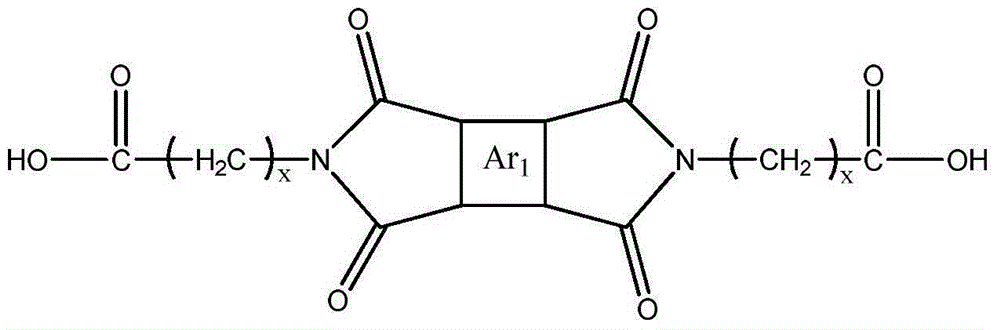

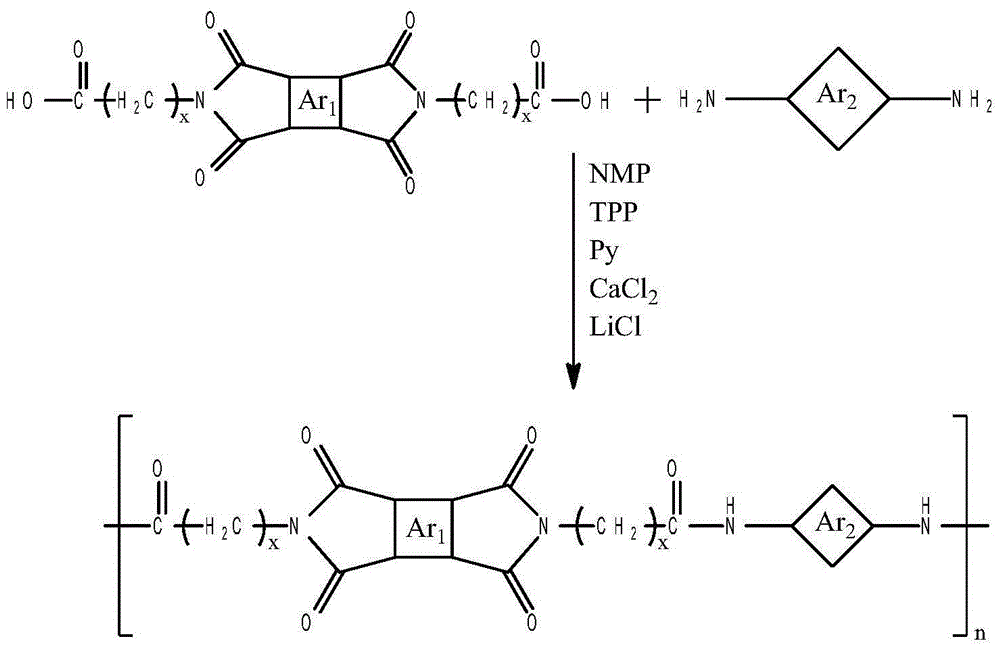

Method used

Image

Examples

Embodiment 1

[0032] (2) Weigh 3.384g (0.005mol) of imide diacid monomer, 0.5515g (0.0051mol) of p-phenylenediamine, NMP15mL, TPP4mL, pyridine 4mL, anhydrous CaCl 2 2g, LiCl 1g. Placed in a 100ml three-necked flask, refluxed with nitrogen gas, mechanically stirred, 80°C for 1h, 90°C for 1h, 100°C for 1h, 120°C for 5h. The reaction solution was settled with ethanol, filtered with suction and the filter residue was collected. Then rinse repeatedly with ethanol and warm water and vacuum dry.

[0033] Embodiment 1 synthesizes final product structural formula as shown in the following formula:

[0034]

[0035] n=10-200.

[0036] The intrinsic viscosity of the product was 1.2 dL / g.

[0037] Example 2

Embodiment 2

[0039] (2) Weigh 3.444g (0.005mol) of imide diacid monomer, 0.5515g (0.0051mol) of p-phenylenediamine, NMP13mL, TPP4mL, pyridine 4mL, anhydrous CaCl 2 2g, LiCl 1g. Placed in a 100ml three-necked flask, refluxed with nitrogen gas, mechanically stirred, 80°C for 1h, 90°C for 1h, 100°C for 1h, 120°C for 5h. The reaction solution was settled with methanol, filtered with suction and the filter residue was collected. Then rinse repeatedly with ethanol and warm water and vacuum dry.

[0040] Embodiment 2 synthesizes final product structural formula as shown in the following formula:

[0041]

[0042] The intrinsic viscosity of the product was 0.95 dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com