High-performance cold and heat resistant PPS, PTFE and MC nylon alloy

A PTFE, high-performance technology, applied in the field of polymer materials, can solve the problems of difficult direct molding and high melt flow rate of PPS, and achieve the effect of high physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dry PPS, PTFE, and MC nylon chips at 110°C for 3 hours, then mix the dried PPS, PTFE, MC nylon chips, toughener, antioxidant, and processing aids in proportion and send them into twin-screw extrusion At the same time, add alkali-free glass fiber to the twin-screw extruder, go through twin-screw high-speed continuous shearing, mixing, extruding from the machine head, drawing, drying, pelletizing, extruding magnetism and packaging.

[0019] Screw temperature: first zone: 290°C, second zone 300°C, third zone 305°C, fourth zone 310°C, die head 310°C.

Embodiment 2

[0021] A kind of high-performance cold-resistant and heat-resistant PPS, PTFE, MC nylon alloy was prepared according to the process conditions in Example 1 and the material ratio in Table 1.

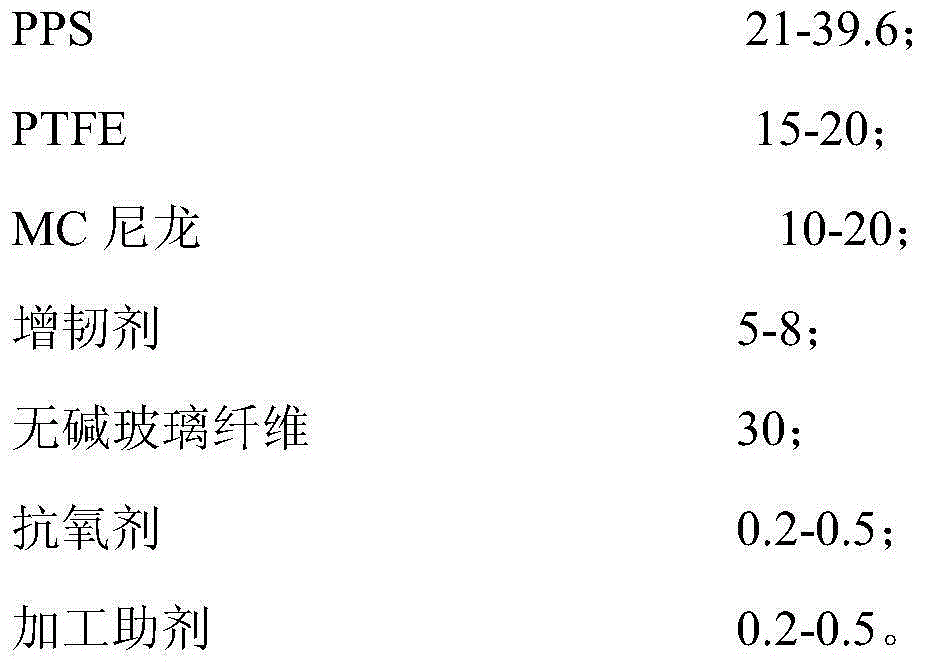

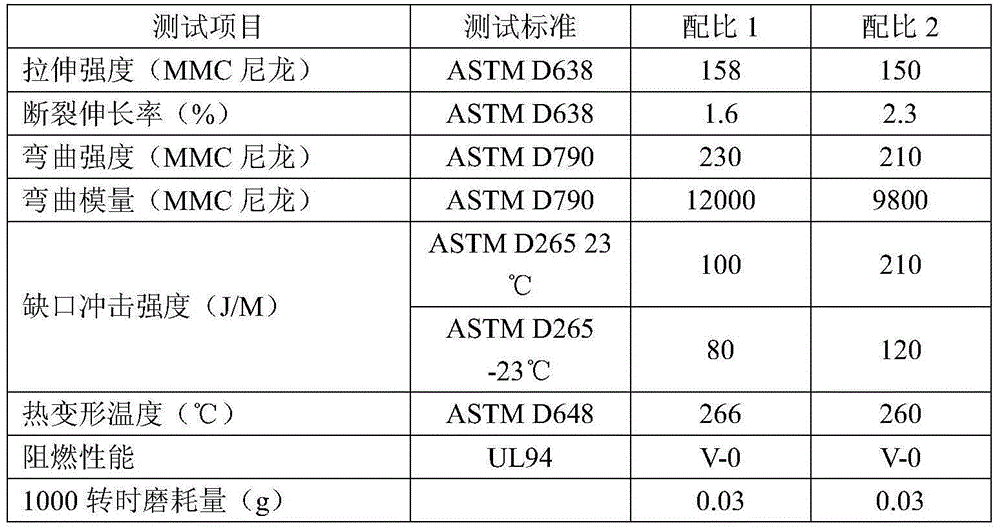

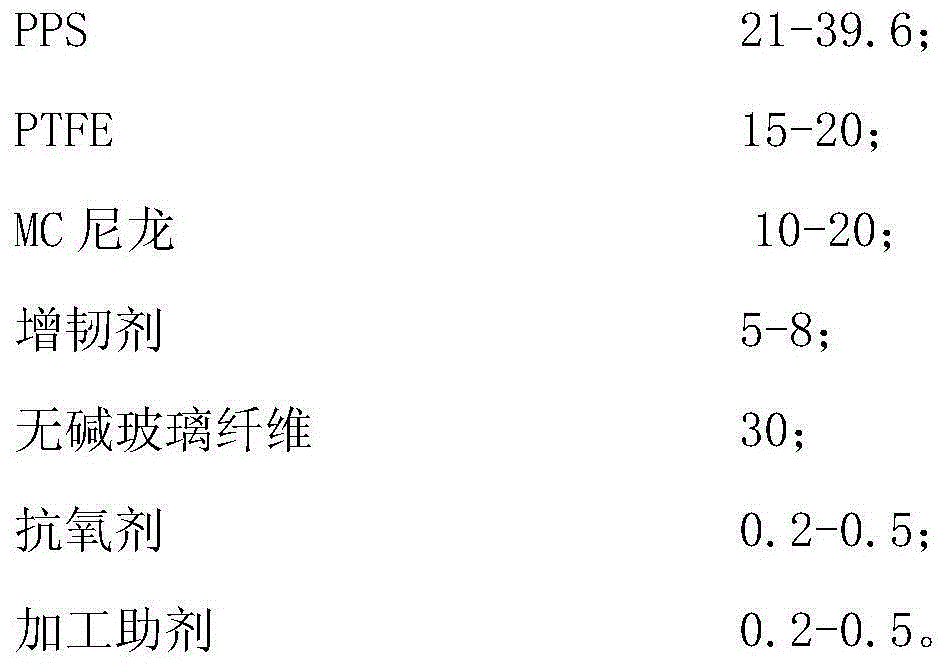

[0022] Table 1 (material proportion is weight percent)

[0023] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com