Multi-component copolymer binder, positive plate including multi-component copolymer binder, and lithium ion battery

A lithium-ion battery, multi-component copolymerization technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems that the surface of active materials cannot be effectively wetted, cannot be coated with active materials, and battery cycle storage performance deteriorates. Achieve the effects of improving the first discharge efficiency, improving high temperature storage performance, and increasing the first gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present application is further described below through specific examples. However, these examples are merely exemplary and do not constitute any limitation to the protection scope of the present application.

[0070] In the following examples, comparative examples, and test examples, the reagents, materials, and instruments used are commercially available unless otherwise specified, and the detected methods and instruments are conventional means and conventional methods unless otherwise specified. instrument.

Embodiment 1 Embodiment 5

[0071] Embodiment 1~Example 5 The preparation of multi-component copolymerization binder 1~5

Embodiment 1

[0072] Embodiment one: the preparation of multi-component copolymerization binder 1:

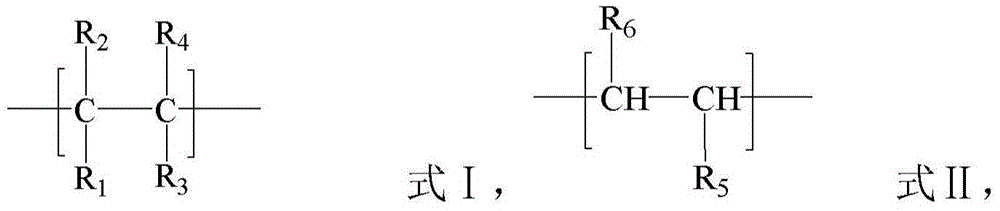

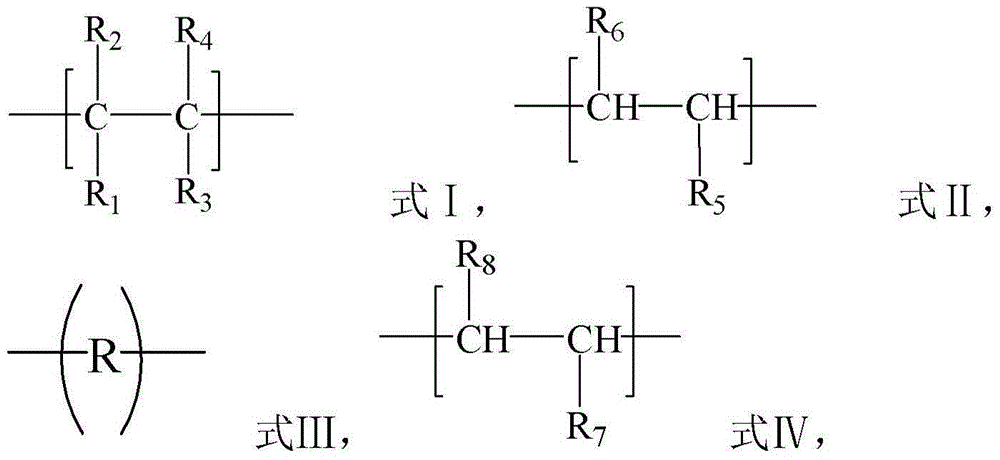

[0073] Multi-component copolymerization binder 1: The multi-component copolymer 1 included is: In formula I ~ formula IV, R 1 for -H,R 3 for -CH 3 , R 2 for -CH 2 CN, R 4 for-COOH, R 5 for-SO 3 H, R 6 for-C 6 h 5 SO 3 H, R is R 7 for-COOCH 2 CH 3 , R 8 for-COOCH(CH 3 ) 2 .

[0074] With a mechanical stirrer, N 2 In the four-necked flask of the protection device and the thermometer, add successively the monomers corresponding to each structural monomer in the polypolymer 1, the initiator azobisisobutyronitrile (accounting for 0.2% of the total monomer weight), the emulsifier OP -10 (accounting for 0.5% of the total monomer weight), dispersant hexadecyl ammonium bromide (accounting for 0.1% of the total monomer weight) and solvent toluene, wherein formula I, formula II, formula III, formula IV each The molar ratio of the corresponding monomer is formula I monomer: formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com