Medicine composition for treating bone fracture and preparation method thereof

A technology for treating fractures and compositions, which is applied in the field of pharmaceutical compositions for treating fractures and its preparation, can solve the problems of slow swelling and pain relief, long treatment courses, and high medical expenses, and achieve easy popularization and application, small toxic and side effects, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

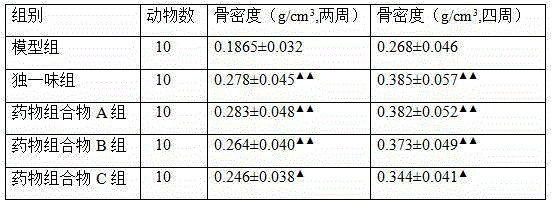

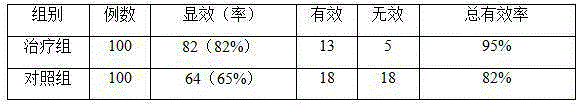

Method used

Image

Examples

Embodiment 1

[0032] The raw materials were weighed according to the following parts by weight: 10 parts of thistle, 15 parts of Panax notoginseng, 14 parts of epimedium, 10 parts of melon seed gold, 12 parts of Rhizoma Chuanxiong, 15 parts of mulberry leaves, 10 parts of rhubarb, 10 parts of Achyranthes bidentata and 10 parts of licorice share.

[0033] Preparation:

[0034] S1: Take mulberry leaves, wash away impurities, dry with hot air at 50°C for 5 hours, control the moisture content to 5%, pulverize, and pass through a 40-mesh sieve to obtain coarse powder; suck the coarse powder into an airflow ultrafine pulverizer for ultrafine pulverization, The crushing pressure is 0.5MPa, the feed rate is 30mg / s, and after drying, carry out superfine pulverization respectively, and pass through a 800 mesh sieve to obtain mulberry leaf superfine powder, which is set aside;

[0035] S2: Take notoginseng, epimedium, melon seed gold, chuanxiong, mulberry leaves, rhubarb, achyranthes bidentata and li...

Embodiment 2

[0039] Weigh the raw materials according to the following parts by weight: 20 parts of large thistle, 30 parts of Panax notoginseng, 28 parts of epimedium, 20 parts of melon seed gold, 28 parts of Chuanxiong, 20 parts of mulberry leaves, 18 parts of rhubarb, 20 parts of Achyranthes bidentata and 20 parts of licorice share.

[0040] Preparation:

[0041] S1: Take mulberry leaves, wash away impurities, dry with hot air at 50°C for 5 hours, control the moisture content to 8%, pulverize, and pass through a 60-mesh sieve to obtain coarse powder; suck the coarse powder into an airflow ultrafine pulverizer for ultrafine pulverization, The crushing pressure is 0.5MPa, the feed rate is 30mg / s, and after drying, carry out superfine pulverization respectively, and pass through a 800 mesh sieve to obtain mulberry leaf superfine powder, which is set aside;

[0042] S2: Take notoginseng, epimedium, melon seed gold, chuanxiong, mulberry leaves, rhubarb, achyranthes bidentata and licorice, was...

Embodiment 3

[0046] The raw materials were weighed according to the following parts by weight: 15 parts of thistle, 28 parts of Panax notoginseng, 20 parts of epimedium, 15 parts of melon seed gold, 16 parts of Chuanxiong, 18 parts of mulberry leaves, 14 parts of rhubarb, 15 parts of Achyranthes bidentata and 15 parts of licorice share.

[0047] Preparation:

[0048] S1: Take mulberry leaves, wash away impurities, dry with hot air at 50°C for 5 hours, control the moisture content to 5%, pulverize, and pass through a 50-mesh sieve to obtain coarse powder; suck the coarse powder into an airflow ultrafine pulverizer for ultrafine pulverization, The crushing pressure is 0.5MPa, the feed rate is 30mg / s, and after drying, carry out superfine pulverization respectively, and pass through a 800 mesh sieve to obtain mulberry leaf superfine powder, which is set aside;

[0049] S2: Take notoginseng, epimedium, melon seed gold, chuanxiong, mulberry leaves, rhubarb, achyranthes bidentata and licorice, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com