Cartilage extracellular matrix and silk fibroin composite orientation cartilage support and preparation method thereof

A technology of silk fibroin and chondrocytes, which is applied in the field of biological tissue engineering, can solve the problems of insufficient pore structure of scaffold materials, achieve good clinical application prospects, avoid immune rejection, and improve biomechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

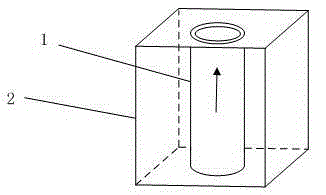

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] 1. Preparation of porcine cartilage extracellular matrix freeze-dried sponge

[0043] Cut fresh porcine articular cartilage tissue, and the operation method is as follows: 1. Soak the cartilage slices in Tris-Hcl buffer solution (containing 0.035mM phenylmethylsulfonyl fluoride) with a pH of 7.5 and a concentration of 0.01M, and pass through a tissue pulverizer (brand BILON; Model DS-1) was pulverized into homogenate; ② Differential centrifugation method was used to obtain cartilage microfilaments of about 500nm-5μm; methylsulfonyl fluoride) for 12 hours; ④ 10000rpm / min after centrifugation and repeated washing with distilled water; It can be obtained after freeze-drying.

[0044] 2. Preparation of silk fibroin solution

[0045] Taking mulberry silk as raw material, the operation method is as follows: 1. silk degumming (soda cooking):...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com