Assembly line system in which service life of lithium ion sieve adsorbents is prolonged and operating method thereof

An operation method and adsorbent technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as slow dissolution and immature recycling technology of waste lithium batteries, so as to prolong service life, reduce chemical dissolution, reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

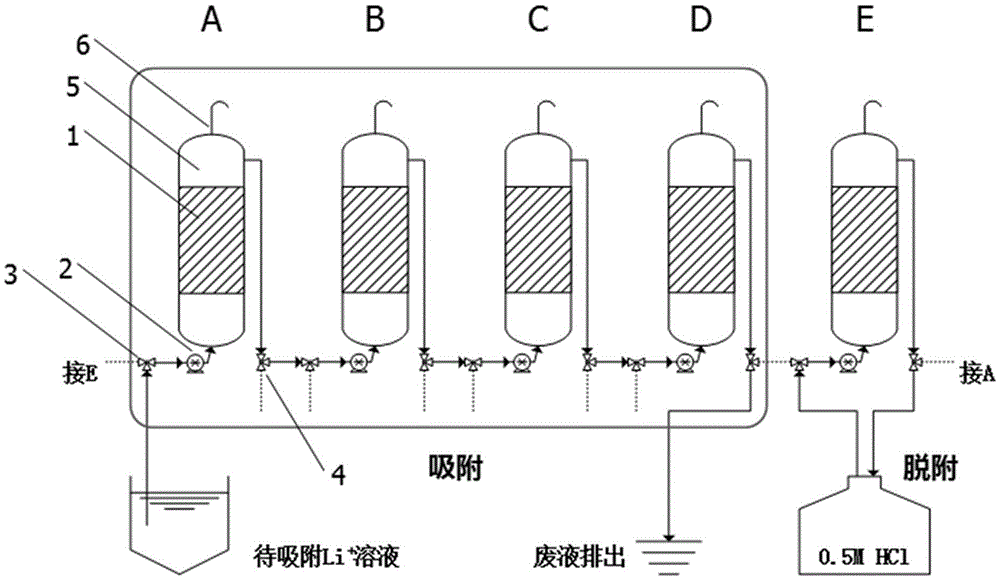

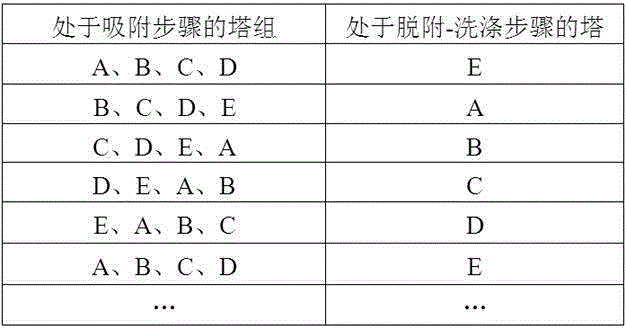

[0045] Set 5 adsorption towers as a group, numbered A, B, C, D, E, and the main component of them is LiMnO 2.5 (Li 1.6 mn 1.6 o 4 ) lithium ion sieve adsorbent particles, pay attention to reserve about 1 / 10 of the buffer space at the top of the tower and keep it open to the atmosphere. Slowly pump in 0.25mol / L dilute sulfuric acid, and the effluent contains desorbed lithium, which is sent to the subsequent process for preparing lithium carbonate for use. HMnO in the desorbed state was obtained after acid washing and sufficient ion exchange treatment 2.5 , into the water to wash quickly for 10 to 15 minutes.

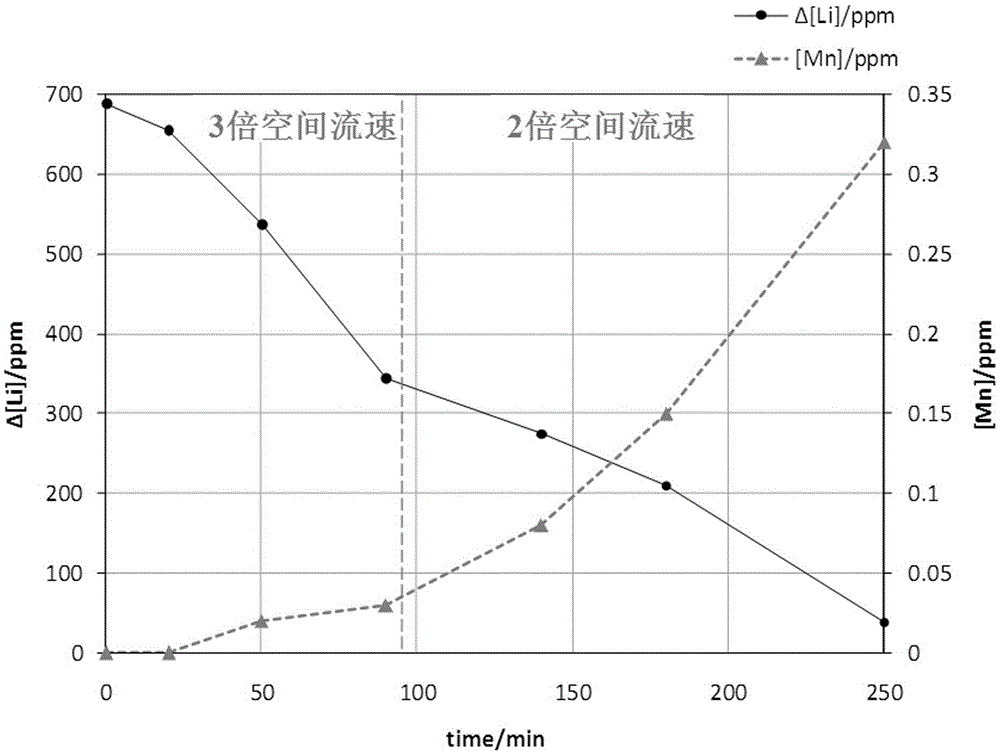

[0046] In the pretreatment pool, adjust the pH of the lithium-containing salt lake brine to be adsorbed to 7~8 with carbonate or NaOH, and then add a certain amount of NaHCO according to the lithium content 3 ——For example, this example uses a solution containing lithium 700ppm, then add NaHCO 3 so that the final concentration [HCO 3 - ]=0.075mol / L; Because the pr...

Embodiment 2

[0054] Carry out with reference to the step of embodiment 1, but only in the pretreatment tank, the lithium-containing brine to be adsorbed is treated with Ca(OH) 2 or NaOH to adjust the pH to about 8.5 without adding NaHCO 3 Carbonate and bicarbonate buffers. This method is suitable for production conditions where cheap carbonate (bi)carbonate cannot be obtained. Since there is no buffer, the adsorption rate drops rapidly at the beginning, so it is necessary to replenish alkali before each tower and reuse the liquid to be adsorbed until the lithium content in it is reduced to A certain value.

[0055] In this example, the initial brine to be adsorbed containing 700ppm of lithium is slowly pumped into the adsorption tower groups A, B, C, and D after pretreatment, and the lithium concentration in the effluent of D tower is monitored. When the value rises rapidly to >300ppm, the effluent Drain back to the pretreatment tank, while using the automatic adjustment device to supple...

Embodiment 3

[0059] Carry out with reference to the step of embodiment 1, but adsorbent is changed into Li 1.33 mn 1.67 o 4 -PVC particles, the adsorbent also has the characteristic of increasing the dissolution loss with the extension of time in the near adsorption saturation state. Therefore, this method can also achieve the same total amount of lithium element adsorption-desorption transfer, and the adsorption-desorption steps can be reduced by about 40%. In Example 1, the lithium ion adsorption saturation capacity of the adsorbent is relatively low, so it approaches adsorption saturation quickly, and the degree of dissolution reduction is not as obvious as in Example 1.

[0060] The present invention aims at the common weakness of various lithium ion sieve adsorbents, that is, in actual use, there is a characteristic that the dissolution loss increases with the prolongation of the adsorption time or desorption time, and adopts a strategy: multiple adsorption towers are cascaded to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com