Nitrogen-containing carbon material for supercapacitosr, preparation method thereof, and supercapacitor electrode material

A technology of supercapacitors and nitrogen-carbon materials, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of limiting the increase of specific capacitance and small specific surface area of carbon materials, and achieve the effect of increasing specific capacitance, increasing specific capacity, and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

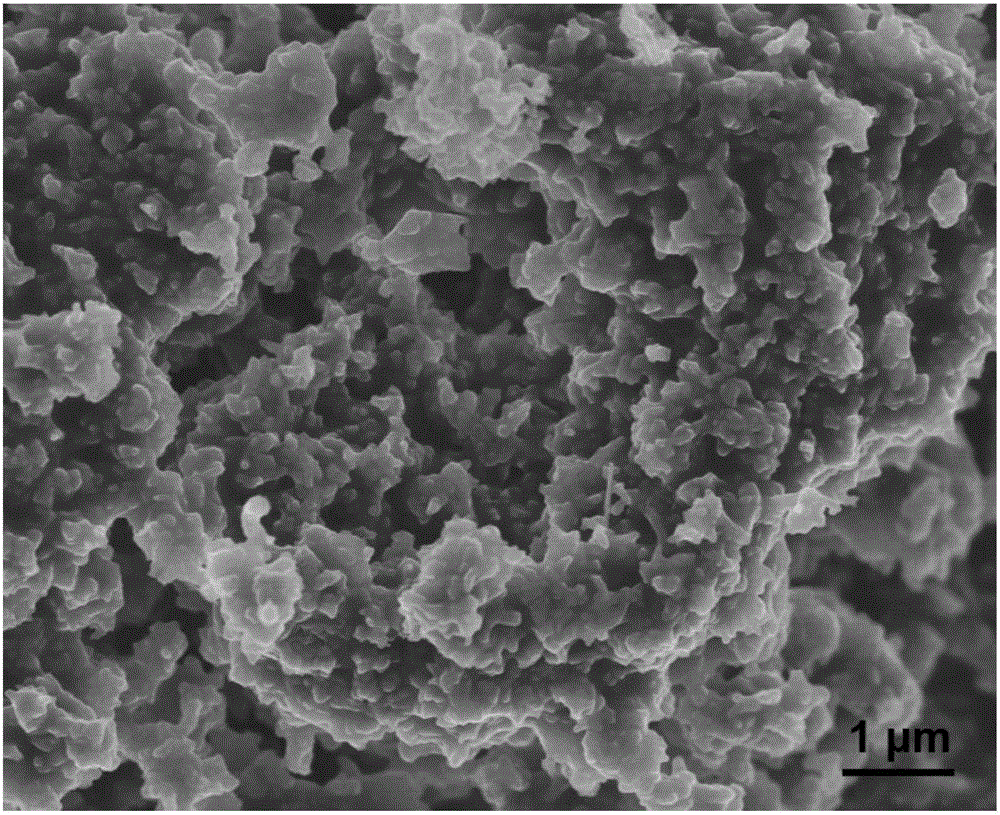

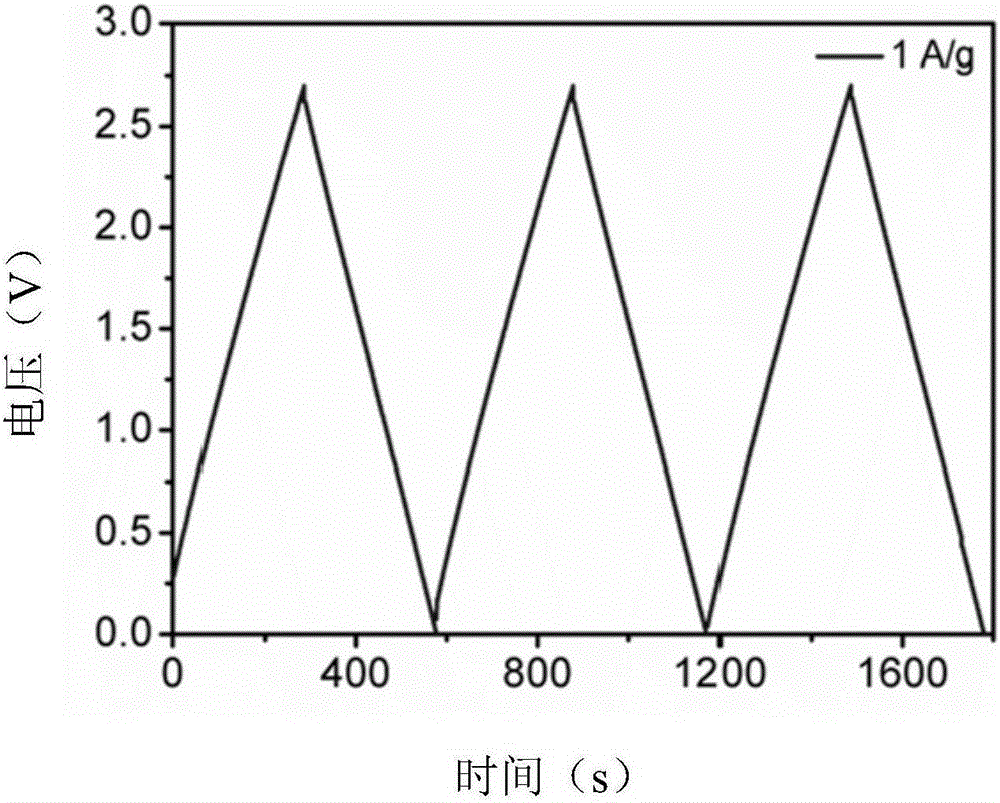

[0038] The preparation method of the supercapacitor nitrogen-containing carbon material of the present embodiment comprises the following steps:

[0039] 1) Polymer preparation: add 2.1g of pyrrole monomer into 150mL of deionized water, stir evenly to make solution A, and pass nitrogen into it for protection; dissolve 5.13g of ammonium persulfate in 50mL of water to form solution B; At 0°C, slowly add solution B dropwise to solution A, stir to allow polymerization to occur, and the reaction time is 6 hours to obtain a pre-polymerization reaction product;

[0040] Transfer the pre-polymerization reaction product into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 12 hours; filter the hydrothermal reaction product with suction, wash with deionized water, filter with suction, wash with ethanol, and filter with suction, until The filtrate was colorless, and the filtered residue was vacuum-dried at 120°C for 12 hours to obtain the polypyrrole produ...

Embodiment 2

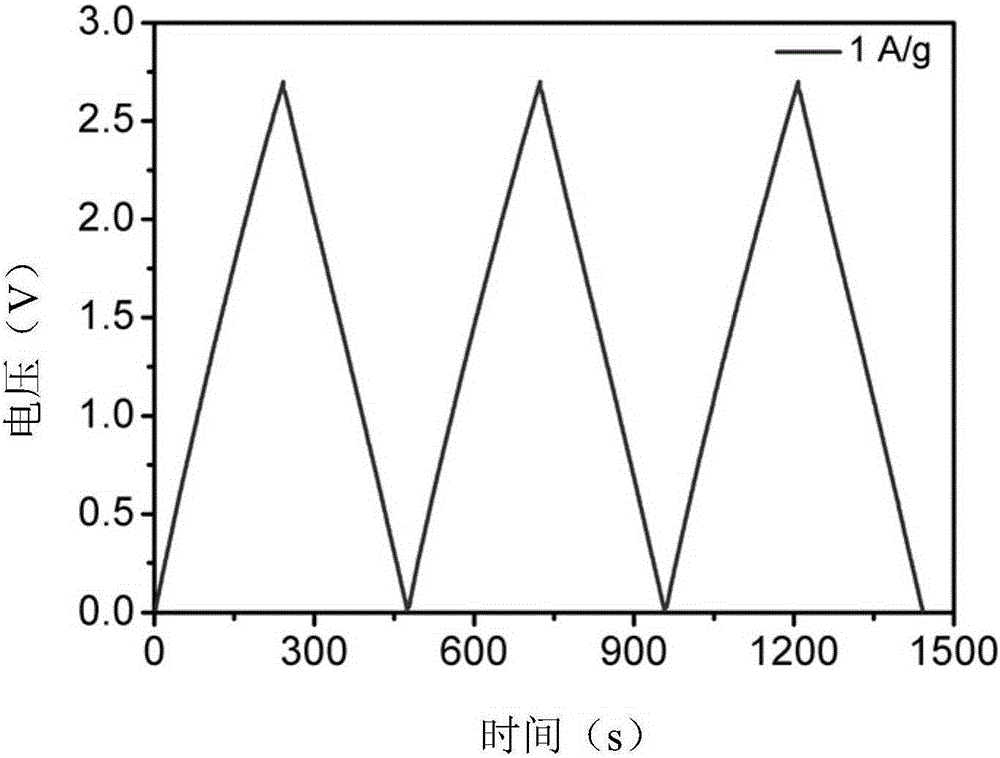

[0046] The preparation method of the nitrogen-containing carbon material of the present embodiment comprises the following steps:

[0047] 1) Add 2.1g of pyrrole monomer into 150mL deionized water, stir evenly to make solution A, and pass nitrogen into it for protection; add 8.0g of FeCl 3 Dissolve in 100mL of water to prepare solution B; slowly add solution B dropwise to solution A at 50°C, stir to allow polymerization to occur, and the reaction time is 6 hours to obtain a pre-polymerization reaction product;

[0048] Transfer the pre-polymerization reaction product into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for a reaction time of 8 hours; suction-filter the hydrothermal reaction product, wash with deionized water, suction-filter, ethanol, and suction-filter until The filtrate was colorless, and the filtered residue was vacuum-dried at 80°C for 12 hours to obtain the polypyrrole product;

[0049] 2) Put the polypyrrole product prepared ...

Embodiment 3

[0054] The preparation method of the nitrogen-containing carbon material of the present embodiment comprises the following steps:

[0055] 1) Add 2.1g of pyrrole monomer into 150mL of deionized water, stir evenly to make solution A, and pass nitrogen into it for protection; add 3.0g of H 2 o 2 Dissolve in 50mL of water to prepare solution B; slowly add solution B dropwise to solution A at 10°C, stir to cause polymerization reaction, and the reaction time is 8 hours to obtain the prepolymerization reaction product;

[0056] Transfer the pre-polymerization reaction product into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for a reaction time of 6 hours; suction-filter the hydrothermal reaction product, wash with deionized water, filter with suction, wash with ethanol, and filter with suction, until The filtrate was colorless, and the filtered residue was vacuum-dried at 60°C for 24 hours to obtain the polypyrrole product;

[0057] 2) Put the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com