Biological regulation preparation method of lead sulfide nanomaterial

A nanomaterial and biological preparation technology, applied in the field of green technology, can solve the problems of high energy consumption, high cost, environmental pollution, etc., and achieve the effects of low energy consumption, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Screening and cultivation of SRB

[0037] 1. The composition of the rich medium of SRB is: 0.1mol / L lactic acid, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 ,0.5g / L yeast extract powder, pH5.0;

[0038] 2. Collect sludge from a sewage treatment plant in Beijing. The sludge samples were placed in SRB enriched medium and placed in anaerobic culture at 32°C. Transplant once every 20 days according to the volume ratio of 20% (seed solution / medium).

[0039] Step 2, the preparation of EDTA-Pb chelate solution

[0040] Preparation of 0.1mol / LEDTA-Pb chelate solution is to contain 0.05mol of Pb 2+ of wastewater and 0.1mol of EDTA-Na 4 Mix and stand at room temperature for 6h before use.

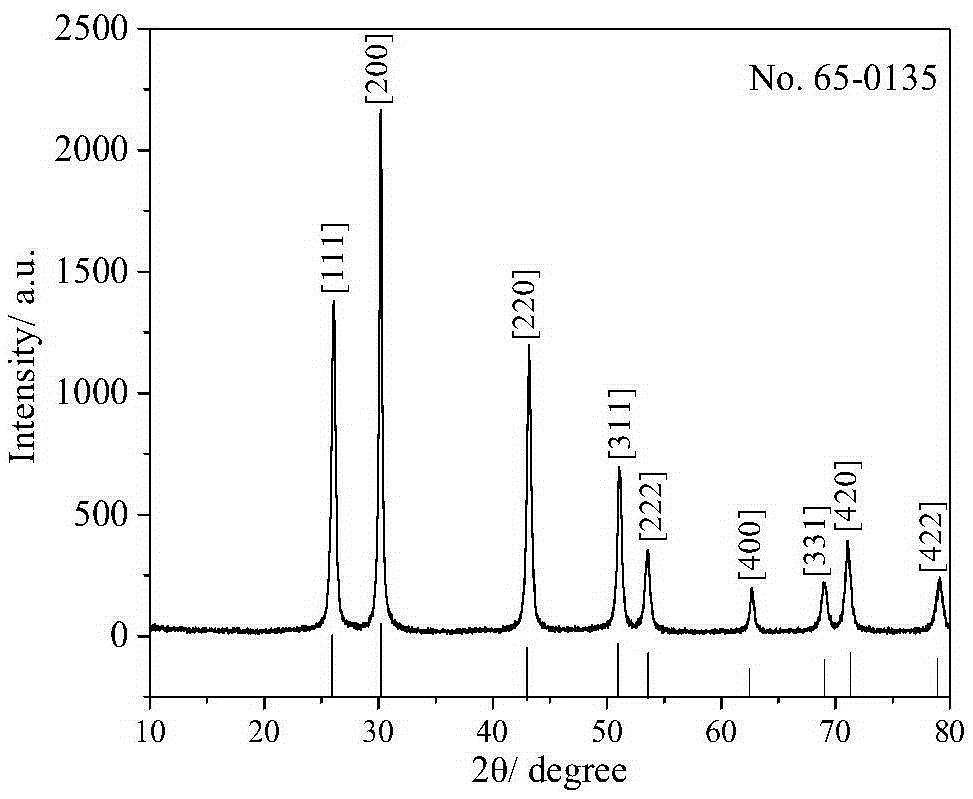

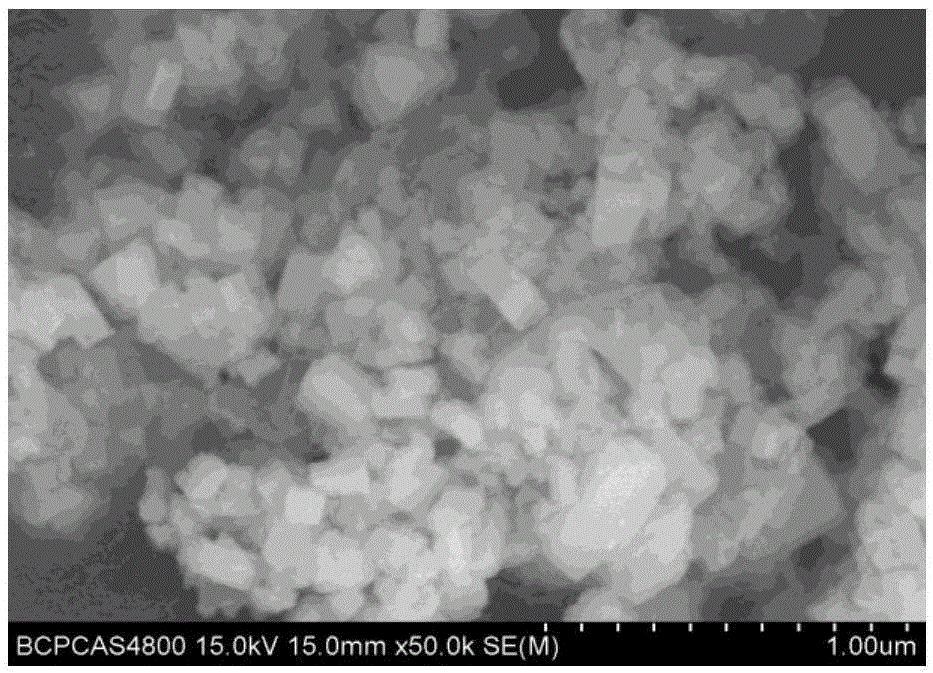

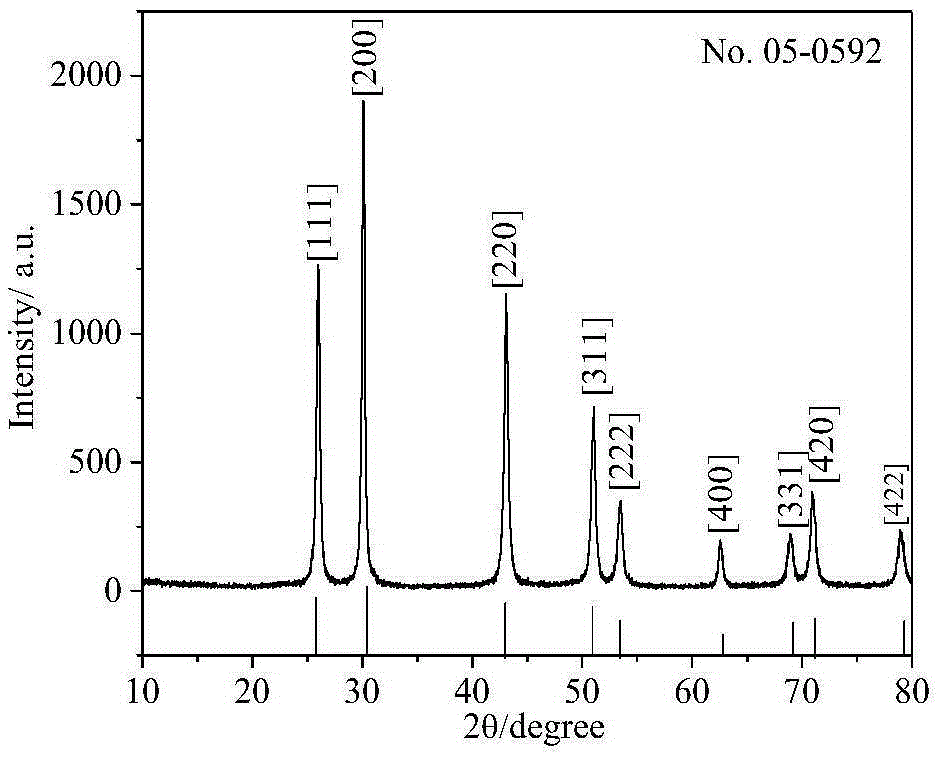

[0041] Step 3, the preparation of lead sulfide nanomaterial

[0042] The composition of the working medium for preparing lead sulfide is: 5.0g / L glucose, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 , 0.5g / ...

Embodiment 2

[0045] Step 1. Screening and cultivation of SRB

[0046] 1. The composition of the rich medium of SRB is: 0.1mol / L lactic acid, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 ,0.5g / L yeast extract powder, pH5.0;

[0047] 2. Collect sludge from a sewage treatment plant in Beijing. The sludge samples were placed in SRB enriched medium and placed in anaerobic culture at 32°C. Transplant once every 20 days according to the volume ratio of 20% (seed solution / medium).

[0048] Step 2, the preparation of EDTA-Pb chelate solution

[0049] Preparation of 0.1mol / LEDTA-Pb chelate solution is to contain 0.05mol of Pb 2+ of wastewater and 0.1mol of EDTA-Na 4 Mix and stand at room temperature for 6h before use.

[0050] Step 3, the preparation of lead sulfide nanomaterial

[0051] The composition of the working medium for preparing lead sulfide is: 5.0g / L glucose, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 , 0.5...

Embodiment 3

[0054] Step 1. Screening and cultivation of SRB

[0055] 1. The composition of the rich medium of SRB is: 0.1mol / L lactic acid, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 ,0.5g / L yeast extract powder, pH5.0;

[0056] 2. Collect sludge from a sewage treatment plant in Beijing. The sludge samples were placed in SRB enriched medium and placed in anaerobic culture at 32°C. Transplant once every 20 days according to the volume ratio of 20% (seed solution / medium).

[0057] Step 2, the preparation of EDTA-Pb chelate solution

[0058] Preparation of 0.1mol / LEDTA-Pb chelate solution is to contain 0.05mol of Pb 2+ of wastewater and 0.1mol of EDTA-Na 4 Mix and stand at room temperature for 6h before use.

[0059] Step 3, the preparation of lead sulfide nanomaterial

[0060] The composition of the working medium for preparing lead sulfide is: 5.0g / L glucose, 8.0g / LNa 2 SO 4 ,1.0g / LNH 4 Cl,0.5g / LKH 2 PO 4 ,0.5g / LMgSO 4 ,0.1g / LCaCl 2 , 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com