AuPd/Fe3O4 in-situ Electro-Fenton catalyst and preparation method and application thereof

A catalyst, fe3o4 technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high energy consumption, unfavorable promotion and application, and increase the complexity of the use process. As well as energy consumption and other issues, to achieve the effect of low energy consumption, low cost and sustainable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] AuPd / substrate-based, and Pd / substrate-based catalysts generate hydrogen peroxide:

[0035] To eliminate Fe 3 o 4 The impact of the substrate on the decomposition of hydrogen peroxide produced, while highlighting the advantages of supporting AuPd alloys in the present invention, the catalyst used in this example is tested on the basis of carbon nanotubes that do not interfere with the decomposition of hydrogen peroxide, wherein in the AuPd alloy The loadings of Au and Pd were 2.5%, respectively, while the loading of the catalyst supporting Pd alone was 5%. Its synthesis method is as follows:

[0036] Weigh 1g of carbon nanotube powder each, and disperse them into two Erlenmeyer flasks A and B filled with 200mL ultrapure water. Palladium solution, add palladium chloride solution containing 0.05gPd to B; after ultrasonication for 5 minutes, stir to make it evenly dispersed; under stirring, use an ice-water bath to lower the temperature of the solution, and after the te...

Embodiment 2

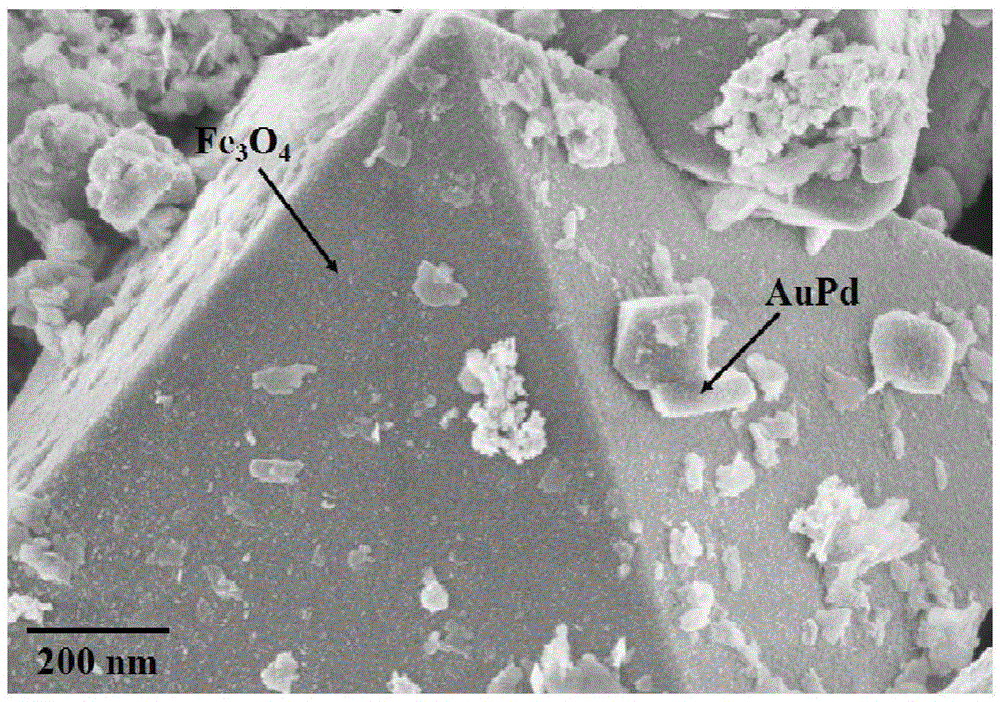

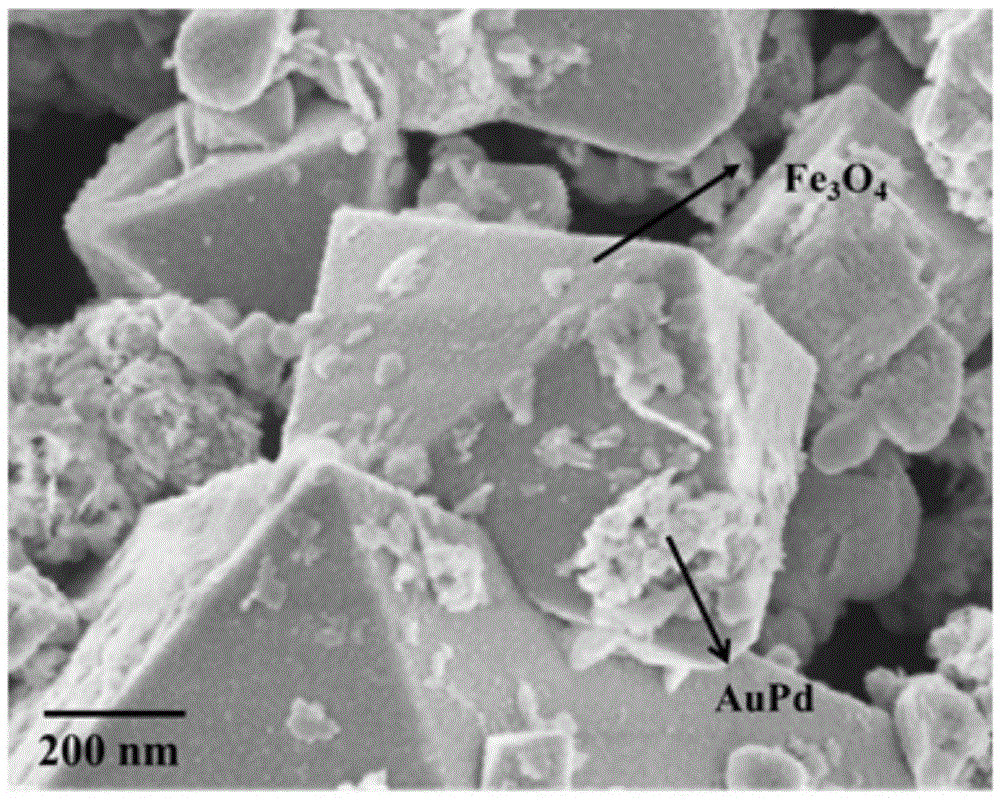

[0043] AuPd / Fe loaded AuPd alloy with 2.5% mass fraction of gold and palladium 3 o 4 In-situ electro-Fenton catalysts, and Pd / Fe with a mass fraction of 5% Pd alone 3 o 4 Preparation of in situ electro-Fenton catalysts:

[0044] 1) Synthetic Catalyst Fe 3 o 4 Substrate: First, 1.5mL hydrazine hydrate aqueous solution (volume fraction 55%) and 1mL0.5mol / L ferrous sulfate solution were vigorously stirred for 30min; then transferred to a 40mL reactor and kept at 200°C for 24h; cooled to room temperature Finally, the obtained solid was washed three times with ultrapure water and ethanol respectively; finally, it was dried in a vacuum oven at 60° C. for 6 h and ground into a powder.

[0045] 2) Synthesis of AuPd / Fe 3 o 4 In-situ electro-Fenton catalyst: Weigh 1 g of Fe synthesized in step 1 3 o 4 Powder, dispersed in 200mL ultrapure water, after ultrasonication for 5min, add a certain amount of palladium chloride and chloroauric acid solution to make it contain 0.025g of A...

Embodiment 3

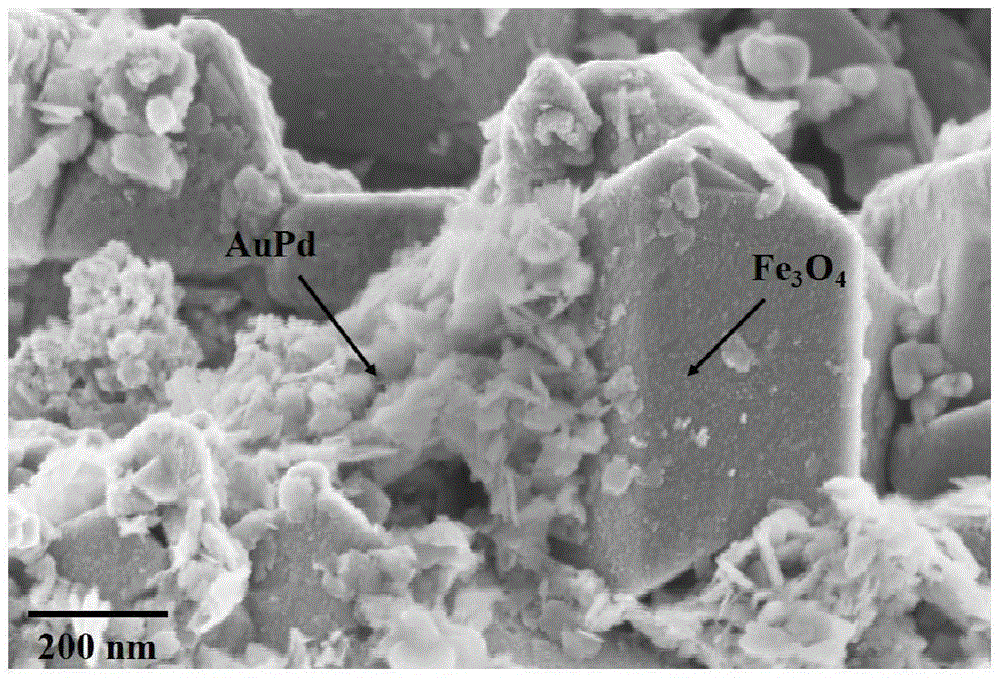

[0054] AuPd / Fe loaded AuPd alloy with 0.5% mass fraction of gold and palladium 3 o 4 In-situ electro-Fenton catalysts, and Pd / Fe with 1% Pd alone 3 o 4 Preparation of in situ electro-Fenton catalysts:

[0055] 1) Synthetic Catalyst Fe 3 o 4 Substrate: First, 1.5mL hydrazine hydrate aqueous solution (volume fraction 55%) and 1mL0.5mol / L ferrous sulfate solution were vigorously stirred for 30min; then transferred to a 40mL reactor and kept at 200°C for 24h; cooled to room temperature Finally, the obtained solid was washed three times with ultrapure water and ethanol respectively; finally, it was dried in a vacuum oven at 60° C. for 6 h and ground into a powder.

[0056] 2) Synthesis of AuPd / Fe 3 o 4 In-situ electro-Fenton catalyst: Weigh 1 g of Fe synthesized in step 1 3 o 4 Powder, dispersed in 200mL ultrapure water, after ultrasonication for 10min, add a certain amount of palladium chloride and chloroauric acid solution to make it contain 0.005g of Au and 0.005g of Pd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com