Invert-demulsion coagulating agent, preparation method of invert-demulsion coagulating agent and application of invert-demulsion coagulating agent

A reverse-phase demulsification and coagulant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of good treatment effect and failure to receive, and achieve high demulsification speed, good demulsification, and improved demulsification Effect of speed and demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

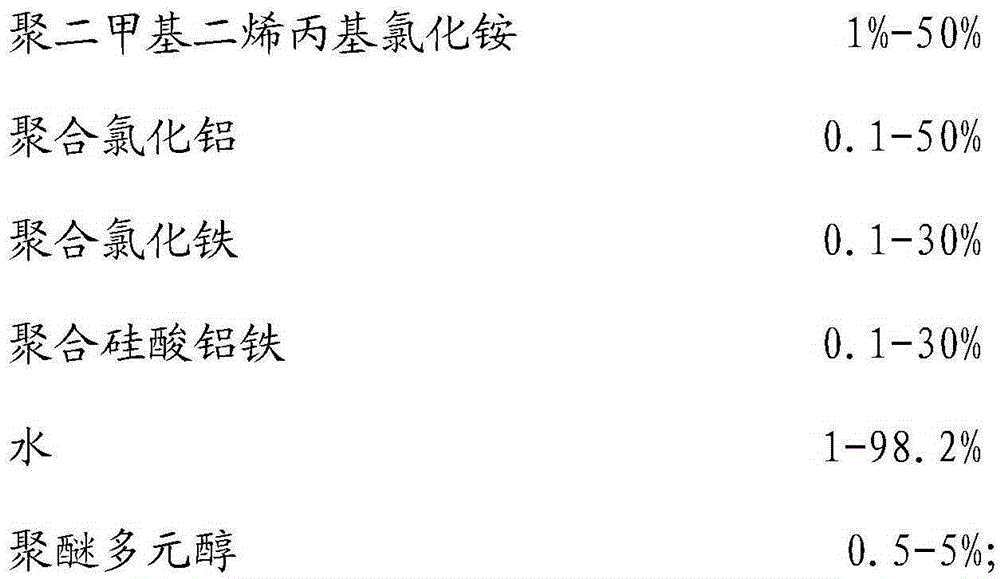

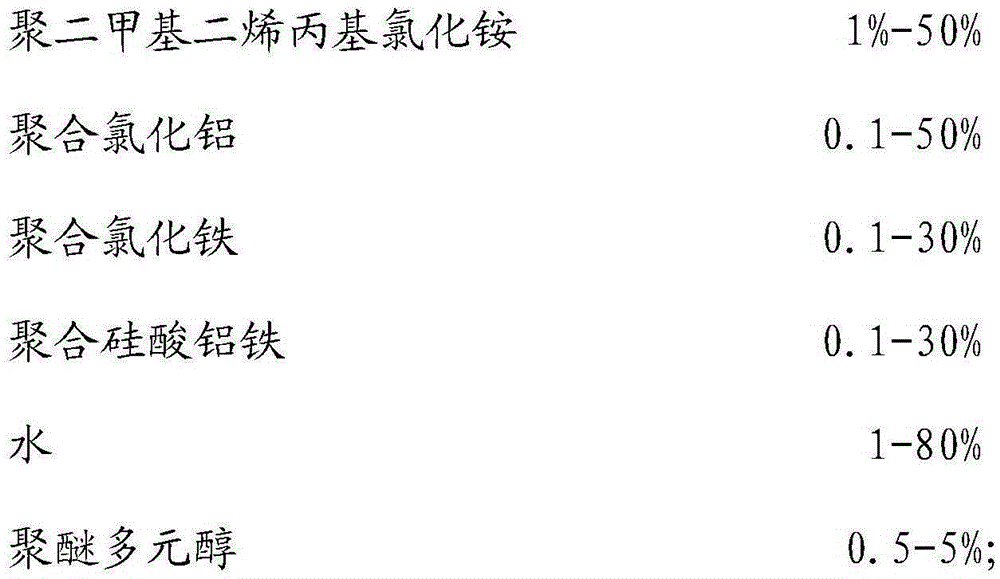

[0031] A reverse-phase demulsification coagulant, prepared by the following method: stirring and dissolving polydimethyldiallyl ammonium chloride in water, adding polyaluminum chloride, polyferric chloride, poly Iron aluminum silicate, heat up to 60°C while stirring, add polyether polyol, stir and react for 130 minutes, then cool down to room temperature; the amount of each component is calculated by mass percentage: polydimethyldiallyl ammonium chloride 1%, polyaluminum chloride 0.1%, polyferric chloride 0.1%, polyaluminum ferric silicate 0.1%, water 98.2%, polyether polyol 0.5%.

Embodiment 2

[0033] A reverse-phase demulsification coagulant, prepared by the following method: stirring and dissolving polydimethyldiallyl ammonium chloride in water, adding polyaluminum chloride, polyferric chloride, poly Iron aluminum silicate, heat up to 80°C while stirring, add polyether polyol, stir and react for 120 minutes, then cool down to room temperature; the amount of each component is calculated by mass percentage: polydimethyldiallyl Ammonium chloride 20%, polyaluminum chloride 30%, polyferric chloride 20%, polyaluminum iron silicate 19.5%, water 10%, polyether polyol 0.5%.

Embodiment 3

[0035] A reverse-phase demulsification coagulant, prepared by the following method: stirring and dissolving polydimethyldiallyl ammonium chloride in water, adding polyaluminum chloride, polyferric chloride, poly Iron aluminum silicate, heat up to 100°C while stirring, add polyether polyol, stir and react for 240 minutes, then cool down to room temperature; the amount of each component is calculated by mass percentage: polydimethyldiallyl Ammonium chloride 45%, polyaluminum chloride 30%, polyferric chloride 10%, polyaluminum iron silicate 5%, water 5%, polyether polyol 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com