A kind of bio-organic fertilizer for organic vegetable cultivation and preparation method thereof

A technology for bio-organic fertilizer and organic vegetables, which is applied to the field of bio-organic fertilizer for organic vegetable planting and its preparation, can solve the problems of low number of beneficial live bacteria, low available nutrients, quality degradation, etc., so as to enhance soil fertility and plant stress resistance. properties, improving yield and quality, and promoting nutrient release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

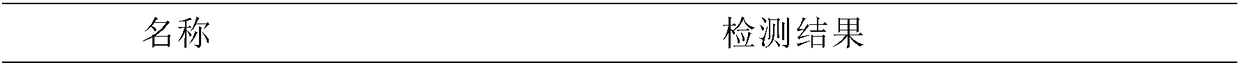

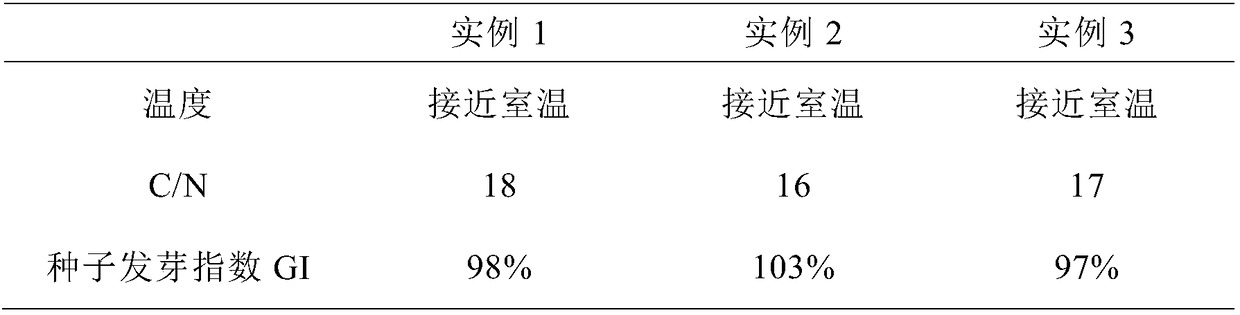

Examples

specific Embodiment 1

[0024] (1) Mixing and composting

[0025] Mix 250Kg of cow dung (by dry weight), 40Kg of wheat straw (by dry weight), 150Kg of biogas residue (by dry weight), and 10Kg of soybean meal (by dry weight), and add 10 times biogas slurry dilution Adjust the moisture content of the compost to 55% for aerobic composting. The temperature monitoring showed that the pile rose to above 50°C after 16 hours and continued until the 7th day. On the 5th day, the pile was turned over and biogas slurry was added to make the moisture content of the pile equal to 50%.

[0026] (2) Inoculation of nitrogen-fixing, phosphorus-dissolving and potassium-dissolving functional bacteria

[0027] On the 9th day, the temperature of the pile dropped below 45°C, turned over and inoculated with 2.5L OD 600 =0.8 Pseudomonas fluorescens (CGMCC deposit number: 5631). On the 14th day, turn over and inoculate with 3L OD 600 =0.8 Pseudomonas chlororaphis (Pseudomonas chlororaphis, CGMCC deposit number: 5628), whi...

specific Embodiment 2

[0030] (1) Mixing and composting

[0031] Mix 300Kg of cow dung (by dry weight), 40Kg of wheat straw (by dry weight), 100Kg of biogas residue (by dry weight), and 10Kg of soybean meal (by dry weight), and add 10 times biogas slurry dilution Adjust the moisture content of the compost to 55% for aerobic composting. The temperature monitoring showed that the pile rose to above 50°C after 20 hours, and continued until the 7th day. On the 5th day, the pile was turned over and biogas slurry was added to make the moisture content of the pile equal to 50%.

[0032] (2) Inoculation of nitrogen-fixing, phosphorus-dissolving and potassium-dissolving functional bacteria

[0033] On the 9th day, the temperature of the pile dropped below 45°C, turned over and inoculated with 3.0L OD 600 =0.8 Pseudomonas fluorescens (CGMCC deposit number: 5631). Turn over and inoculate 3.0L OD on the 14th day 600 =0.8 Pseudomonas chlororaphis (Pseudomonas chlororaphis, CGMCC deposit number: 5628), while ...

specific example 3

[0037] (1) Mixing and composting

[0038] Mix 275Kg of cow dung (by dry weight), 45Kg of wheat straw (by dry weight), 115Kg of biogas residue (by dry weight), and 15Kg of soybean meal (by dry weight), and add 10 times biogas slurry dilution Adjust the moisture content of the compost to 55% for aerobic composting. The temperature monitoring showed that the pile rose to above 50°C after 20 hours, and continued until the 7th day. On the 5th day, the pile was turned over and biogas slurry was added to make the moisture content of the pile equal to 50%.

[0039] (2) Inoculation of nitrogen-fixing, phosphorus-dissolving and potassium-dissolving functional bacteria

[0040] On the 9th day, the temperature of the pile dropped below 45°C, turned over and inoculated with 3.0L OD 600 =0.8 Pseudomonas fluorescens (CGMCC deposit number: 5631). Turn over and inoculate 3.0L OD on the 14th day600 =0.8 Pseudomonas chlororaphis (Pseudomonas chlororaphis, CGMCC preservation number: 5628), whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com