A method for preparing 5-hydroxymethylfurfural from glucose

A technology of hydroxymethylfurfural and glucose, which is applied in the field of 5-hydroxymethylfurfural, can solve the problems of high price of ionic liquid, unfavorable industrial production, high catalyst toxicity, etc., and achieve large-scale production, good economy and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

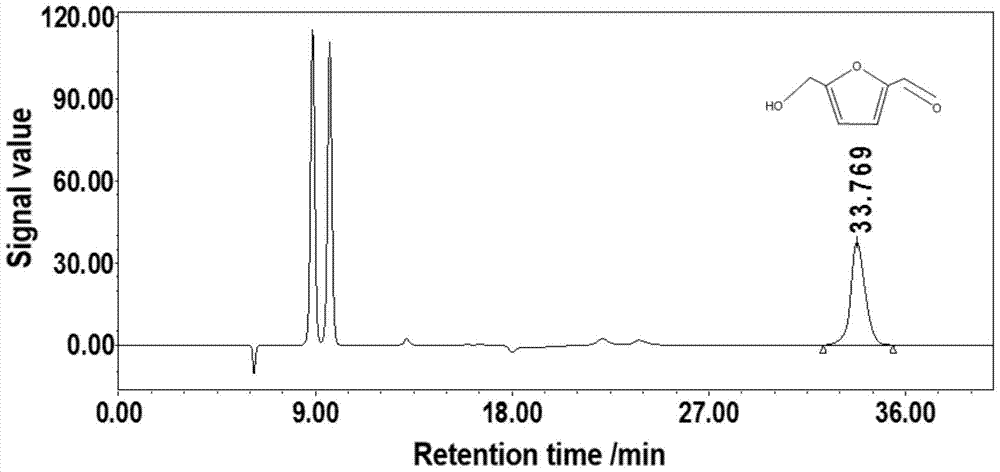

Embodiment 1

[0034] Add 50g of water, 2.5g of glucose, 3g of choline chloride and 0.3ml of hydrochloric acid (37%) into a 100mL round bottom flask, fully dissolve. The flask was placed in a water bath for heating reaction at a temperature of 100° C., and the reaction time was 4 h. After the reaction, the 5-hydroxymethylfurfural obtained by the reaction was extracted with acetonitrile, and the acetonitrile was separated by distillation under reduced pressure to obtain the product 5-hydroxymethylfurfural. The molar yield of the product was 0.86mol% as determined by HPLC.

Embodiment 2

[0036] Add 50g of water, 2.5g of glucose, 0.2g of choline, and 0.1g of borax into a 100mL round-bottomed flask to fully dissolve. The flask was placed in a water bath, and the heating reaction was carried out under N2 atmosphere, the temperature was 30° C., and the reaction time was 20 h. After the reaction was completed, water was distilled off under reduced pressure. Add 0.3ml of hydrochloric acid (37%) to the residue to neutralize the reaction solution, then add 3g of choline chloride to mix, place in a water bath for heating reaction, the temperature is 90°C, and the reaction time is 6h. After the reaction, the 5-hydroxymethylfurfural obtained by the reaction was extracted with acetonitrile, and the acetonitrile was distilled and separated under reduced pressure to obtain the product 5-hydroxymethylfurfural. The molar yield of the product was 22.5 mol% as determined by HPLC.

Embodiment 3

[0038] Add 50g of water, 2.5g of glucose, 0.2g of choline, and 0.1g of borax into a 100mL round-bottomed flask to fully dissolve. The flask was placed in a water bath, and the heating reaction was carried out under N2 atmosphere at a temperature of 55° C., and the reaction time was 8 h. After the reaction was completed, water was distilled off under reduced pressure. Add 0.3ml of hydrochloric acid (37%) to the residue to neutralize the reaction solution, then add 3g of choline chloride to mix, place in a water bath for heating reaction, the temperature is 90°C, and the reaction time is 6h. After the reaction, the 5-hydroxymethylfurfural obtained by the reaction was extracted with acetonitrile, and the acetonitrile was separated by distillation under reduced pressure to obtain the product 5-hydroxymethylfurfural. The molar yield of the product was 20.4 mol% as determined by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com