Method for preparing monodisperse active function polymer microspheres by means of active free radical dispersion polymerization

A technology of dispersion polymerization and functional polymer, which is applied in the field of preparation of monodisperse active functional polymer microspheres, can solve the problems of difficult control of reaction conditions, complicated process steps, etc., and achieves a wide range of applicable monomers and controllable polymerization process. , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

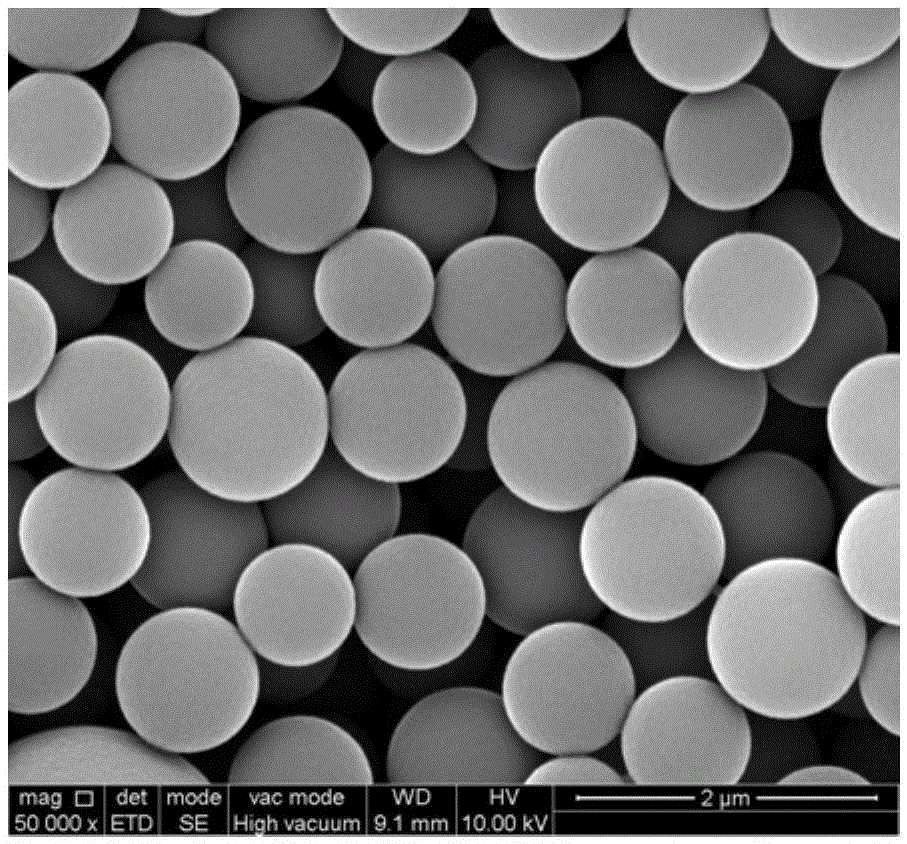

[0022] In a 250mL three-necked quartz flask with a stirring device, add 10g of p-chloromethylstyrene, 0.1g of N,N-diethyldithiocarbamate (4-vinyl)benzyl (Iniferter), 0.1g of polyvinylpyrrolidone Mixed solutions of 1g and 100g of ethanol and water (the mass-number ratio of ethanol and water is 90:10). After stirring evenly, pass nitrogen gas for 30 minutes, keep nitrogen atmosphere, stir at a speed of 200 r / min, and polymerize for 15 hours at 25 °C at a distance of 15 cm from an ultraviolet light source (300 W). After the reaction, centrifuge at high speed to obtain polymer particles, then wash the polymer microspheres with ethanol and deionized water three times in sequence, and dry them in a vacuum oven to constant weight to obtain monodisperse active functional polymer microspheres.

[0023] see figure 1 , The particle size of the polymer microspheres obtained in Example 1 is 0.90 micron, the particle size distribution is 1.012, and the yield is 47%.

Embodiment 2

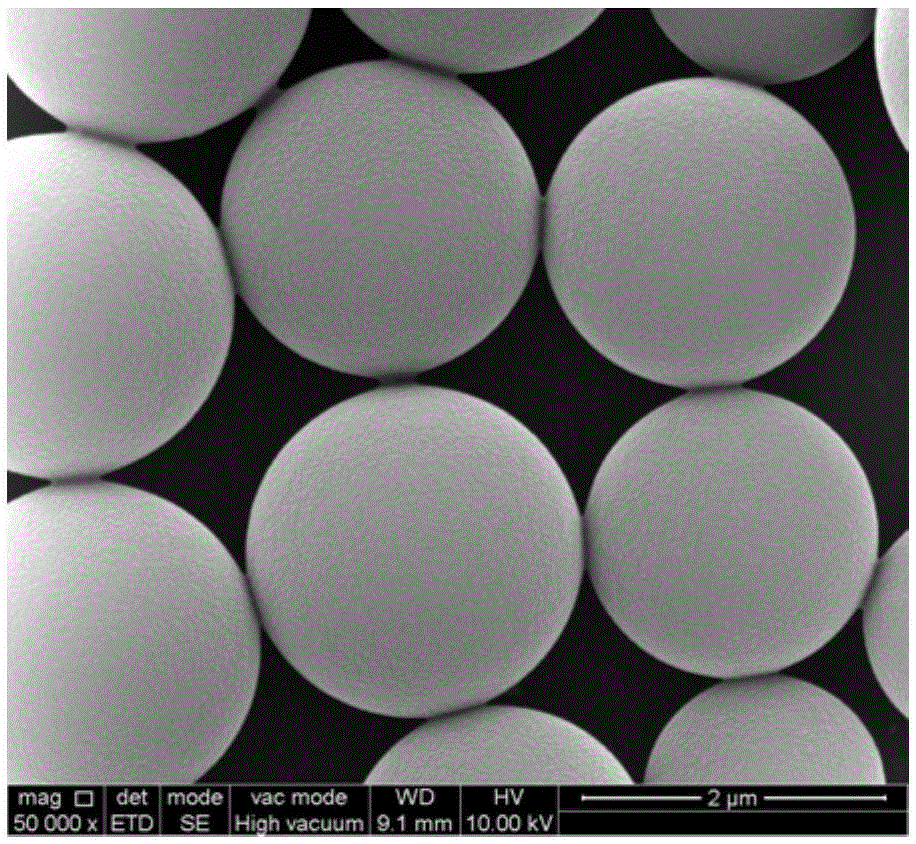

[0025] In a 250mL three-necked quartz flask with a stirring device, add 30g of p-chloromethylstyrene, 0.3g of N,N-diethyldithiocarbamate (4-vinyl)benzyl (Iniferter), 0.3g of polyvinylpyrrolidone Mixed solutions of 1.5g and 100g of ethanol and water (the mass-number ratio of ethanol and water is 90:10). After stirring evenly, pass nitrogen gas for 30 minutes, keep the nitrogen atmosphere, stir at 200r / min, and polymerize at 25°C at a distance of 15cm from the ultraviolet light source (300W) for 24 hours. After the reaction, centrifuge at high speed to obtain polymer particles, then wash the polymer microspheres with ethanol and deionized water three times in sequence, and dry them in a vacuum oven to constant weight to obtain monodisperse active functional polymer microspheres.

[0026] see figure 2 , The particle size of the polymer microspheres obtained in Example 2 is 2.14 microns, the particle size distribution is 1.009, and the yield is 61%.

Embodiment 3

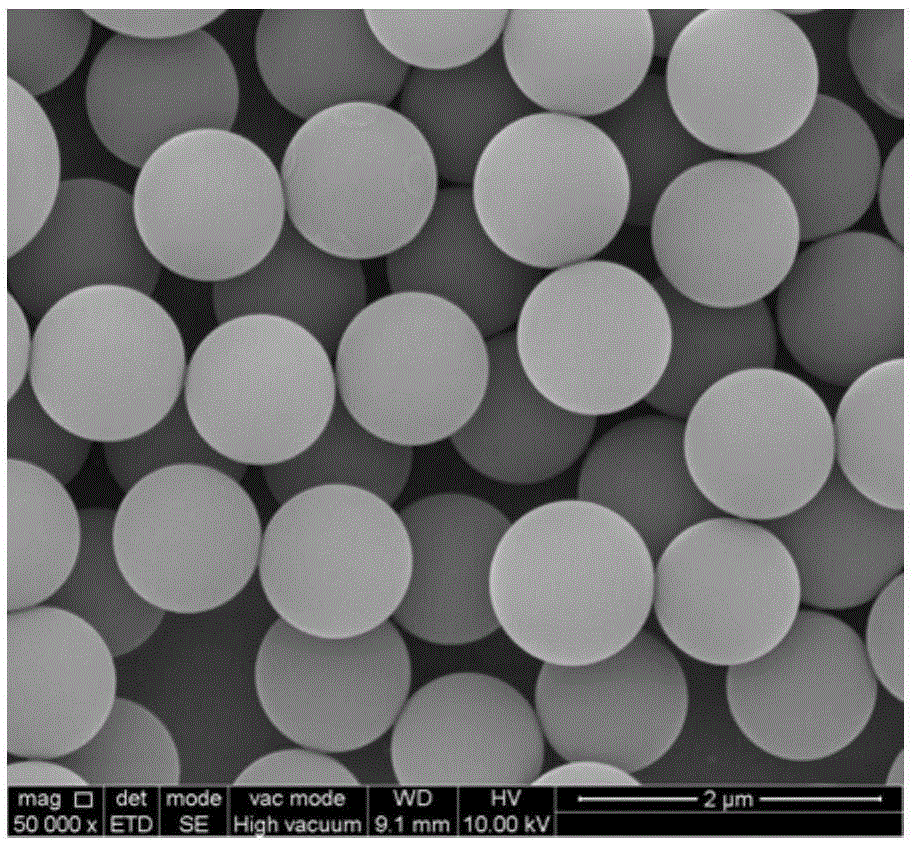

[0028] In a 250mL three-necked quartz flask with a stirring device, add 10g of p-chloromethylstyrene, 0.1g of N,N-diethyldithiocarbamate (4-vinyl)benzyl ester (Iniferter), polyethylene A mixed solution of 1.5 g of pyrrolidone and 100 g of ethanol and water (the mass-number ratio of ethanol to water is 85:15). After stirring evenly, pass nitrogen gas for 30 minutes, keep nitrogen atmosphere, stir at a speed of 200 r / min, and polymerize for 15 hours at 25 °C at a distance of 15 cm from an ultraviolet light source (300 W). After the reaction, centrifuge at high speed to obtain polymer particles, then wash the polymer microspheres with ethanol and deionized water three times in sequence, and dry them in a vacuum oven to constant weight to obtain monodisperse active functional polymer microspheres.

[0029] see image 3 , The particle size of the polymer microspheres obtained in Example 3 was 1.06 microns, the particle size distribution was 1.076, and the yield was 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com