Hydrophobic and oleophobic coating with super-long durable corrosion resistance and low surface energy and preparation process of hydrophobic and oleophobic coating

A low surface energy, durable technology, used in anti-corrosion coatings, coatings, epoxy coatings, etc., can solve problems such as long-term anti-corrosion difficulties, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

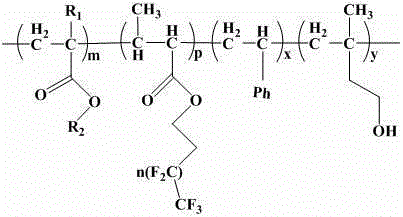

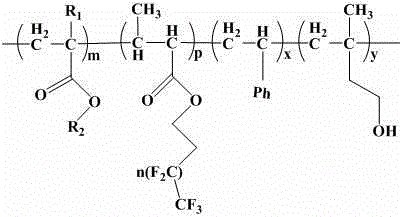

Image

Examples

Embodiment 1

[0052] The preparation process of the ultra-long and durable anti-corrosion low surface energy hydrophobic and oil-repellent coating of this embodiment includes the following processing steps:

[0053] 1) Preparation of epoxy anti-corrosion primer

[0054] Add bisphenol A epoxy resin E20 and organic mixed solvent into the dispersion tank, fully disperse for 10 minutes, add additives, anti-corrosion agents, pigments and fillers in turn, stir and disperse for 10 minutes, then ball mill for 6 hours, check the viscosity and fineness Obtain the class A component of the epoxy anticorrosion primer.

[0055] In this example, the proportion of component A of the epoxy anticorrosion primer coating is as follows:

[0056] Bisphenol A epoxy resin E20: 32 grams

[0057] Pigments and fillers: 20 grams of iron oxide red, 5 grams of mica iron oxide, 1 gram of fumed silica, 2.5 grams of organic bentonite

[0058] Anticorrosion agent: 1.6 grams of polyaniline, 6 grams of aluminum tripolyphos...

Embodiment 2

[0068] 1) Preparation of epoxy anti-corrosion primer

[0069] The preparation process of component A of the epoxy anticorrosion primer is the same as in Example 1 in this example.

[0070] In this example, the proportion of component A of the epoxy anticorrosion primer coating is as follows:

[0071] Bisphenol A epoxy resin E20: 32 grams

[0072] Pigments and fillers: 20 grams of iron oxide red, 5 grams of mica iron oxide, 1 gram of fumed silica, 2.5 grams of organic bentonite

[0073] Anticorrosion agent: 1.6 grams of cetylpyridinium bromide, 6 grams of aluminum tripolyphosphate, 3 grams of aluminum silver paste

[0074] Additives: BYK1630.8g, BYK4100.4g, BYK0520.4g, BYK3000.4g

[0075] Mixed solvent: xylene 12 grams, n-butanol 15 grams

[0076] Take component A of epoxy anti-corrosion primer and polyamide curing agent in a mass ratio of 8:1, compound and mix evenly, spray and pretreat the surface of carbon steel.

Embodiment 3

[0082] 1) The preparation process of component A of the epoxy anticorrosion primer in this example is the same as that in Example 1.

[0083] In this example, the proportion of component A of the epoxy anticorrosion primer coating is as follows:

[0084] Bisphenol A epoxy resin E44: 28 grams

[0085] Pigments and fillers: 20 grams of iron oxide red, 5 grams of mica iron oxide, 1 gram of fumed silica, 2.5 grams of organic bentonite

[0086] Anticorrosion agent: 1.6 grams of cetylpyridinium bromide, 6 grams of aluminum tripolyphosphate, 4 grams of aluminum silver paste

[0087] Additives: BYK1630.8g, BYK4100.4g, BYK0520.4g, BYK3000.4g

[0088] Mixed solvent: xylene 15 grams, n-butanol 15 grams

[0089] 2) Preparation of fluorine-modified acrylate topcoat

[0090] Preparation of fluorine-modified acrylic resin

[0091] Add 30 grams of xylene and N,N-dimethylformamide mixed organic solvent with a mass ratio of 2:1 into the reaction flask, add 25 grams of methyl methacrylate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com