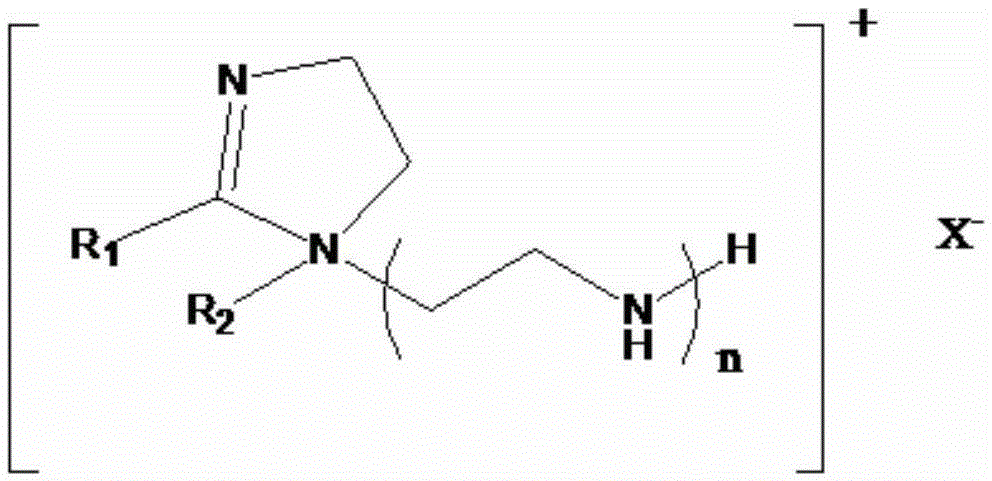

Novel imidazoline compound corrosion inhibitor and preparation method thereof

A technology of corrosion inhibitor and imidazoline, which is applied in the field of new imidazoline compound corrosion inhibitor and its preparation, can solve the problems of poor corrosion inhibitor effect, and achieve the effect of good stability, high efficiency and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 (preparation of imidazoline quaternary ammonium salt)

[0020] a) Add oleic acid (0.1mol), diethylenetriamine (0.12mol) and xylene (40ml) into a reactor equipped with reflux, stirring, and water separation devices, heat up to 150°C under stirring, and keep warm for 3h, Continue to raise the temperature to 220°C, keep it warm for 2h, until no water is formed in the reaction system, then cool down to 100°C, add benzyl chloride (0.1mol), react for 3h, and finally remove low boilers by distillation under reduced pressure to obtain imidazoline quaternary ammonium salt a .

[0021] b) Add oleic acid (0.1mol), ethylenediamine (0.12mol), toluene (40ml) and aluminum oxide (0.2g) into a reactor equipped with reflux, stirring, and water separation devices, and heat up under stirring Heat to 150°C, keep warm for 2h, continue to heat up to 220°C, keep warm for 1h, until no water is formed in the reaction system, then cool down to 100°C, add benzyl chloride (0.11mol), r...

Embodiment 2

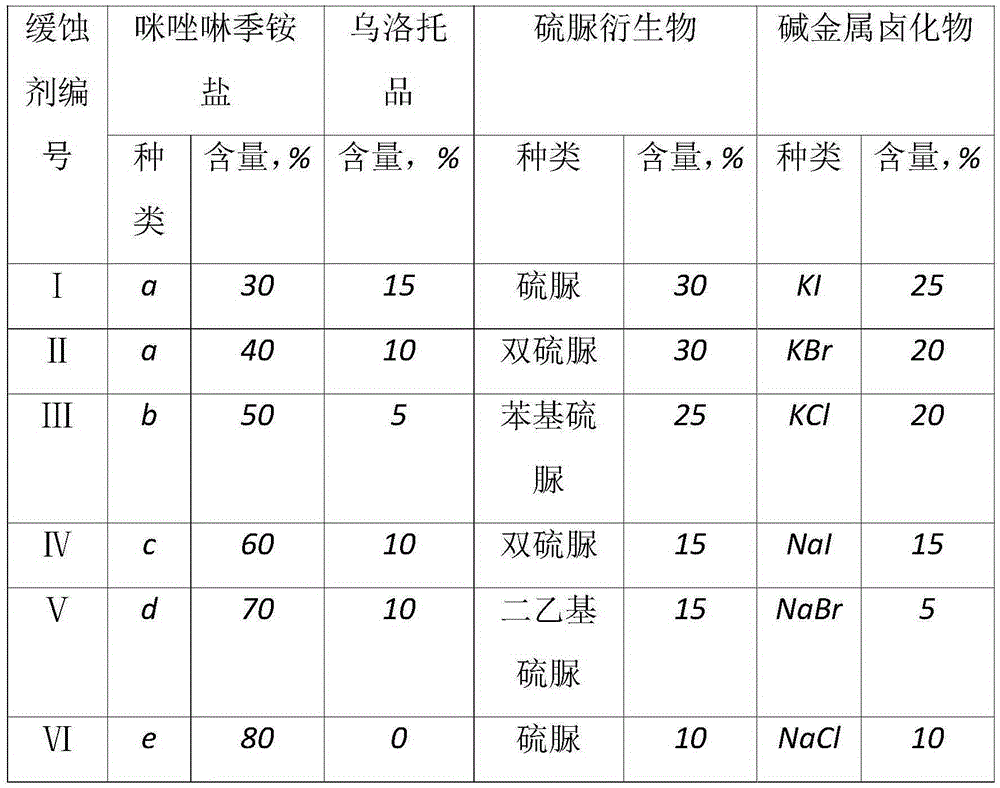

[0025] Embodiment 2 (compound)

[0026] According to imidazoline quaternary ammonium salts a, b, c, d, e prepared in Example 1 and thiourea or its derivatives, alkali metal halides and urotropine are compounded to prepare different types of corrosion inhibitors, Its active ingredients and their quality ratios are shown in Table 1.

[0027] Table 1

[0028]

Embodiment 3

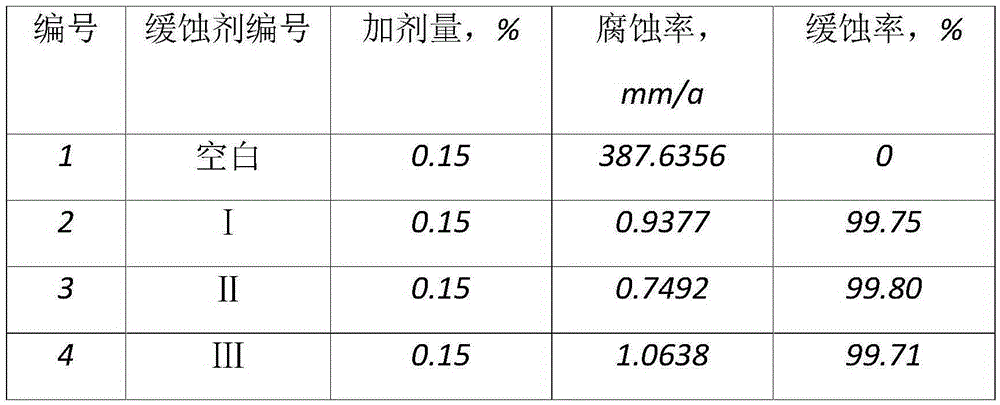

[0029] Embodiment 3 (evaluation)

[0030] Dilute the corrosion inhibitor compounded above into an aqueous solution with a mass ratio of 20%, and then use different types of acid solutions as corrosion media, and use the static evaluation method to evaluate the corrosion inhibition effect (dosing is based on the corrosion inhibitor before dilution). Mass meter), the experimental results are shown in Table 2-4.

[0031] Table 2 Comparison of corrosion inhibition effects of various compound corrosion inhibitors and commercial pickling corrosion inhibitor RX-302 in 5% sulfuric acid

[0032]

[0033]

[0034] Note: Test conditions: normal pressure, temperature 90°C, time 3h; test material: A3 steel;

[0035] Table 3 Comparison of corrosion inhibition effects of various compound corrosion inhibitors and commercial pickling corrosion inhibitor RX-302 in 6% glacial acetic acid

[0036] serial number

Corrosion inhibitor number

Add dose, %

Corrosion rate, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com