Method for making wool fabric have antibacterial and anti-static functions

An antistatic and wool technology, which is applied in the field of making wool fabrics have antibacterial and antistatic properties, and can solve problems such as unstable antibacterial and antistatic properties and cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for making wool fabrics have antibacterial and antistatic properties, the specific steps of which are:

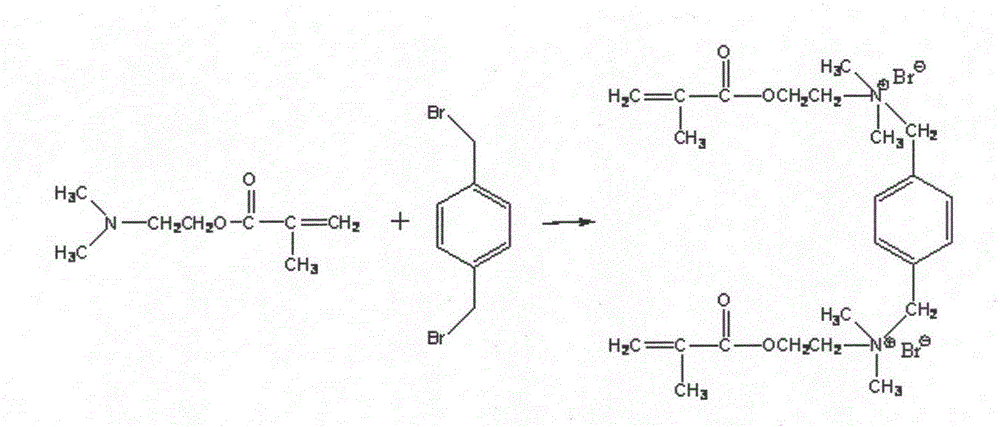

[0027] (1) Synthesis of Gemini quaternary ammonium salt IDMA:

[0028] a. Weigh 4.083g of white powder BbmBP into a 250mL three-neck flask, add acetone drop by drop, and stir while adding, until the white solid is just completely dissolved. Fix the three-necked flask on the iron clip of the heat-collecting electromagnetic stirrer, add 4.764g DMAEMA in the dropping funnel, and add dropwise to the three-necked flask. After the dropwise addition, the temperature was raised to 50° C., and the reaction was stirred under reflux for 24 hours.

[0029] b. After the reaction is complete, take out the product, filter it with a suction filter bottle, and wash and filter it with acetone and carbon tetrachloride respectively to obtain a white solid, which is the relatively pure Gemini quaternary ammonium salt IDMA.

[0030] c. drying the synthesized product after sucti...

Embodiment 2

[0040] A method for making wool fabrics have antibacterial and antistatic properties, the specific steps of which are:

[0041] (1) Synthesis of Gemini quaternary ammonium salt IDMA:

[0042] a. Weigh 6.125g of white powder BbmBP into a 250mL three-neck flask, add acetone dropwise, and stir while adding, until the white solid is just completely dissolved. Fix the three-necked flask on the iron clip of the heat-collecting electromagnetic stirrer, add 7.146g of DMAEMA into the dropping funnel, and add dropwise to the three-necked flask. After the dropwise addition, the temperature was raised to 55° C., and the reaction was stirred under reflux for 18 hours.

[0043] b. After the reaction is complete, take out the product, filter it with a suction filter bottle, and wash and filter it with acetone and carbon tetrachloride respectively to obtain a white solid, which is the relatively pure Gemini quaternary ammonium salt IDMA.

[0044] c. drying the synthesized product after suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com