A clean process for preparing tungsten disulfide in a closed loop

A technology of tungsten disulfide and closed-circuit circulation, which is applied in the fields of tungsten compounds, inorganic chemistry, chemical instruments and methods, etc., which can solve the problems that the mixed powder cannot be fully dispersed and activated, the reaction efficiency and the purity of reaction products are reduced, and the production efficiency and equipment use are affected. efficiency and other issues, to achieve the effect of maximizing the utilization of resources, significant economic and social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

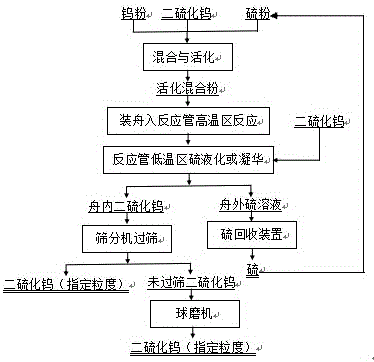

Image

Examples

Embodiment 1

[0023] Weigh 2000 grams of tungsten powder, mix the ingredients according to the molar ratio of tungsten powder, sulfur powder and tungsten disulfide as 1000:2000:1, mix in the mixer for 30 minutes, transfer to the mill for ball milling for 120 minutes, and then load multiple 5L ceramics In the boats, they are sent to the segmented reaction tubes that have been replaced with argon in turn, first to the high temperature zone, the temperature is 600°C, and the frequency of adding boats is controlled so that each ceramic boat stays in the high temperature zone for 1 hour, and then enters the segmented reaction tubes The low temperature zone is 112°C to 445°C, and the residence time is 1h. At the same time, the vacuum device filled with tungsten disulfide adds tungsten disulfide from the side wall of the low temperature zone to the bottom tube wall, so that the liquid flow out from the bottom tube wall of the low temperature zone. The sulfur solution contained 0.05% tungsten disulf...

Embodiment 2

[0025] Weigh 2000 grams of tungsten powder, mix the ingredients according to the molar ratio of tungsten powder, sulfur powder and tungsten disulfide as 1000:6000:50, mix in the mixer for 10 minutes, transfer to the mill for ball milling for 15 minutes, and then load multiple 5L ceramics In the boats, they are sequentially sent to the segmented reaction tubes that have been replaced with argon at a temperature of 650°C in the high temperature zone. ~445°C, residence time 1h, at the same time, the vacuum device containing tungsten disulfide adds tungsten disulfide from the side wall of the low temperature zone to the down side tube wall, so that the sulfur solution flowing out from the liquid outlet on the down side tube wall of the low temperature zone contains 8% tungsten disulfide, then the ceramic boat is pushed into the cooling area, the residence time is 0.5h, the ceramic boat is cooled to room temperature, and black powder is obtained, which is hexagonal flaky nano-tungst...

Embodiment 3

[0027] Weigh 2000 grams of tungsten powder, mix according to the molar ratio of tungsten powder, sulfur powder and tungsten disulfide as 1000:3000:10, mix in a mixer for 10 minutes, transfer to an abrasive mill for ball milling for 15 minutes, and then load into multiple 5L boats In the process, they are sequentially sent to the segmented reaction tubes that have been replaced with argon at a high temperature zone of 650°C, and the frequency of adding boats is controlled so that each ceramic boat stays in the high temperature zone for 3 hours, and then enters the low temperature zone of the segmented reaction tube at 112°C~ At 445°C, the residence time is 1h. At the same time, the vacuum device containing tungsten disulfide adds tungsten disulfide from the side wall of the low temperature zone to the down side tube wall, so that the sulfur solution flowing out of the liquid outlet on the down side tube wall of the low temperature zone contains disulfide. Tungsten sulfide 2%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com