Waste-liquid zero-discharge processing apparatus and waste-liquid processing method

A treatment device and zero-emission technology, applied in the direction of gaseous effluent wastewater treatment, combined devices, separation methods, etc., can solve the problems of increased energy consumption, aggravated ash deposition and scaling, etc., to reduce losses, enhance high-intensity sound wave energy, Improvement of equipment utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

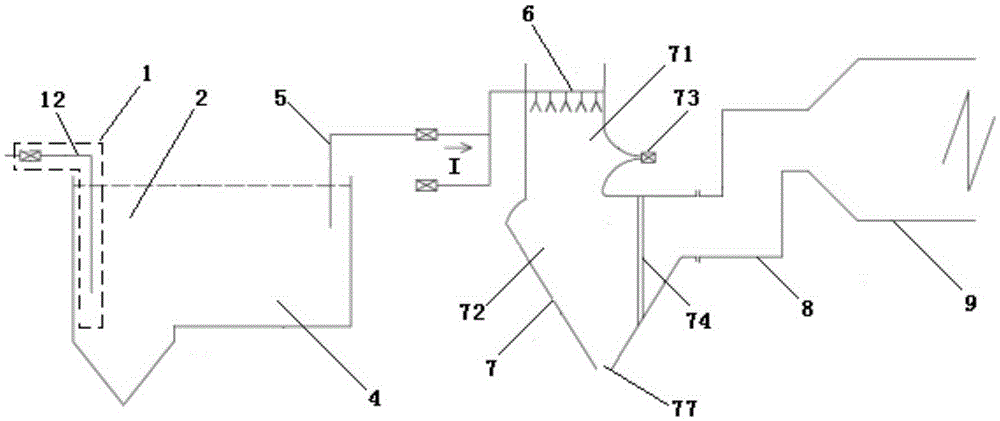

[0049] Such as figure 1 As shown, it is a schematic diagram of the waste liquid zero discharge treatment device provided in the embodiment. It can be seen that the whole device includes waste liquid conveying equipment 1, pre-sedimentation tank 2, buffer tank 4, atomization equipment 6, and solid-liquid-gas separation device 7 And the dedusting device 9, wherein the water delivery pipe 12 of the waste liquid delivery equipment 1 extends into the pre-sedimentation tank 2, the pre-settling tank 2 communicates with the buffer tank 4, and the buffer tank 4 is connected with the atomization device 6 through the water delivery pipe 5; The atomization equipment includes a high-pressure pump 61, an air compressor 62, an atomization pipeline, and an atomization nozzle; the solid-liquid-gas separation device 7 includes a top inlet, and an atomization zone 71 is arranged below the top inlet, and a static pressure zone 71 is arranged below the atomization zone 71. The expansion area 72, t...

Embodiment 2

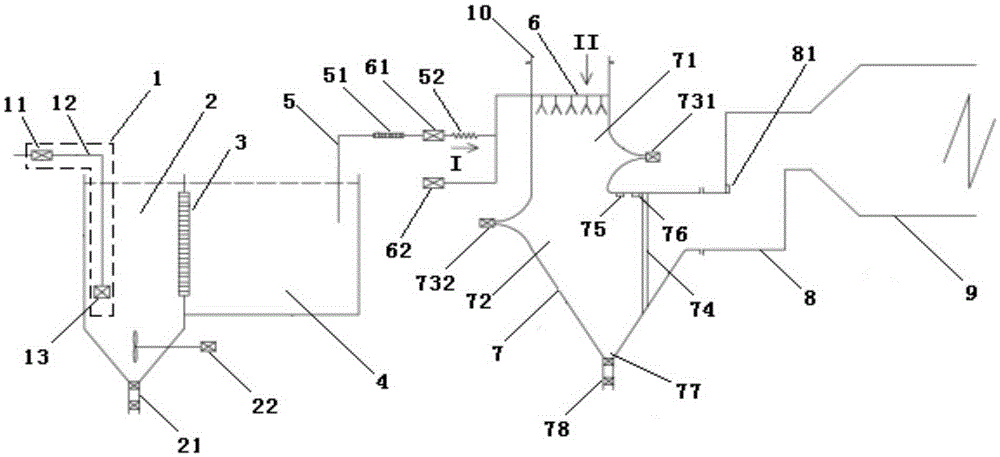

[0052] Such as figure 2 As shown, it is a schematic diagram of the waste liquid zero discharge treatment device provided in this embodiment. It can be seen that it has been further improved on the basis of Embodiment 1, wherein the waste liquid conveying equipment 1 includes a slurry pump 11 and a water delivery pipe 12 And the decompression flow equalization device 13, the decompression flow equalization device 13 is arranged at the water delivery outlet of the water delivery pipe 12, the decompression flow equalization device 13 gradually expands the capacity of the end of the water delivery pipe 12 to form a pressure buffer zone, and is set in the pressure buffer zone One or more layers of orifice plates with uniform perforation rate reduce the pressure and decelerate the liquid flowing out of the water delivery pipe 12 and flow through the orifice plates. The waste water enters the pre-sedimentation tank 2 after decompression and uniform flow, which is more conducive to t...

Embodiment 3

[0055] Taking the desulfurization wastewater of a 1000MW unit of a power plant using the waste liquid zero discharge treatment device provided by the present invention as an example, the specific treatment method of the waste liquid zero discharge treatment device provided by the present invention will be described. Specifically include the following steps:

[0056](1) The desulfurization waste water after the desulfurization of the desulfurization tower is sent to the pre-sedimentation tank 2 by the slurry pump 11 through the water delivery pipe 12 through the decompression and flow equalization device 13, and then reaches the pre-sedimentation tank 2, and is stirred at a constant speed by the agitator 22 in the pre-settling tank 2 This makes the precipitation distribution more uniform, and the supernatant after preliminary precipitation separation is filtered by the first filter 3 and then reaches the buffer pool 4 .

[0057] (2) After the waste water in the buffer pool 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com