A kind of high thermal conductivity graphite foam/carbon composite material and preparation method thereof

A technology of high thermal conductivity graphite and carbon composite materials, applied in the preparation/purification of carbon, etc., can solve the problems of limited improvement of thermal conductivity, high price, long cycle, etc., achieve preparation cost and cycle compression, improve impregnation efficiency, good mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

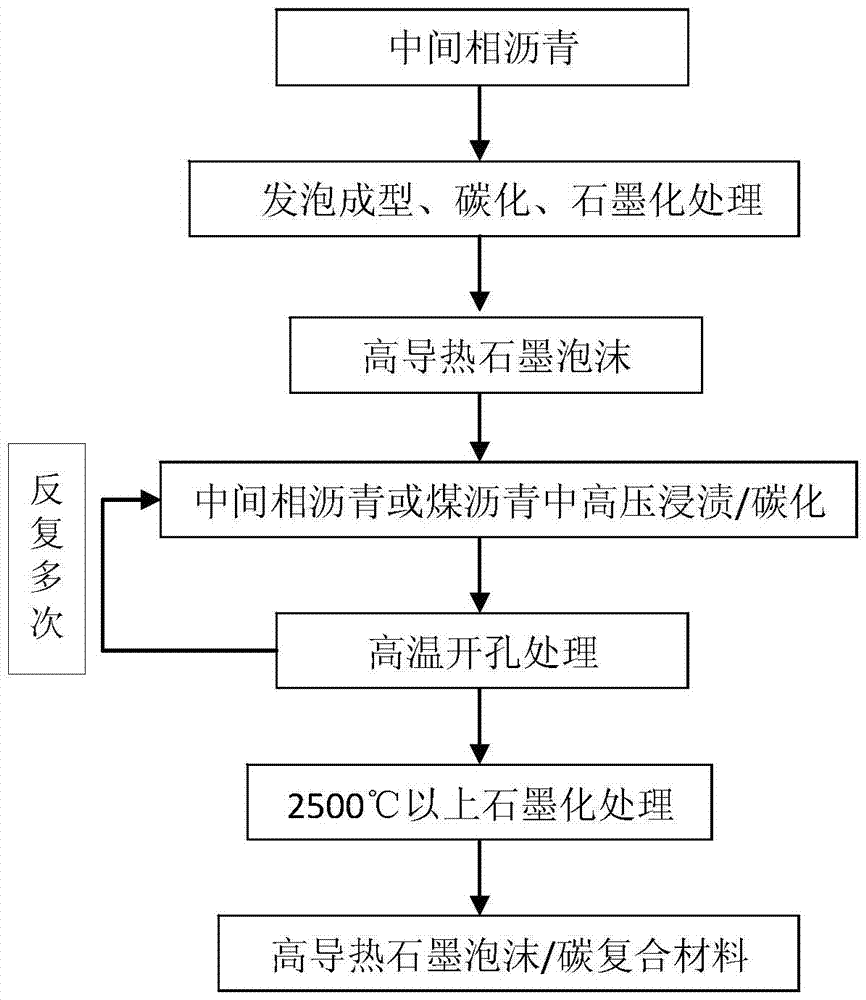

Method used

Image

Examples

Embodiment 1

[0044] (1) Using mesophase pitch with a softening point of 275°C, foaming and molding at a pressure of 7.0 MPa and a temperature of 330°C, and preparing high thermal conductivity graphite foam as a reinforcing base through carbonization at 900°C and graphitization at 3000°C. Preparation of graphite foam reinforced matrix with a density of 0.60g / cm 3 , the thermal conductivity is 138W / m·K, the porosity is 73%, and the open porosity is greater than 90%.

[0045] (2) Put the graphite foam reinforcing base prepared in step (1) into a coal pitch dipping tank, embed the graphite foam with coal pitch, close the lid and heat up to 200°C and vacuumize to -0.1MPa, heat preservation and pressure After 1 hour, pressurize to 15MPa, heat and hold pressure for 4 hours, then cool down freely.

[0046] (3) Put the sample impregnated with coal tar pitch in step (2) into a carbonization furnace for normal pressure carbonization. The carbonization process curve is: room temperature ~ 350 ° C, he...

Embodiment 2

[0053] (1) Using mesophase pitch with a softening point of 275°C, foaming and molding at a pressure of 7.5MPa and a temperature of 330°C, and preparing high thermal conductivity graphite foam as a reinforcing base through carbonization at 900°C and graphitization at 3000°C. Preparation of graphite foam reinforced matrix with a density of 0.65g / cm 3 , the thermal conductivity is 152W / m·K, the porosity is 71%, and the open porosity is greater than 90%.

[0054] (2), put the graphite foam reinforcing base prepared in step (1) into the mesophase pitch impregnation tank, wrap around the graphite foam with mesophase pitch, close the lid and heat up to 330°C and vacuumize to -0.1MPa, keep warm After holding the pressure for 1 hour, pressurize to 25MPa, keep the temperature and hold the pressure for 4 hours, and then cool down freely.

[0055] (3) Put the sample impregnated with mesophase pitch in step (2) into a carbonization furnace for normal pressure carbonization. The carbonizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com