Method for purifying double-function glutathione synthetase

A technology of glutathione and purification method, applied in biochemical equipment and methods, enzymes, ligases, etc., can solve the problems of high cost, long time, low enzyme recovery rate, etc. Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

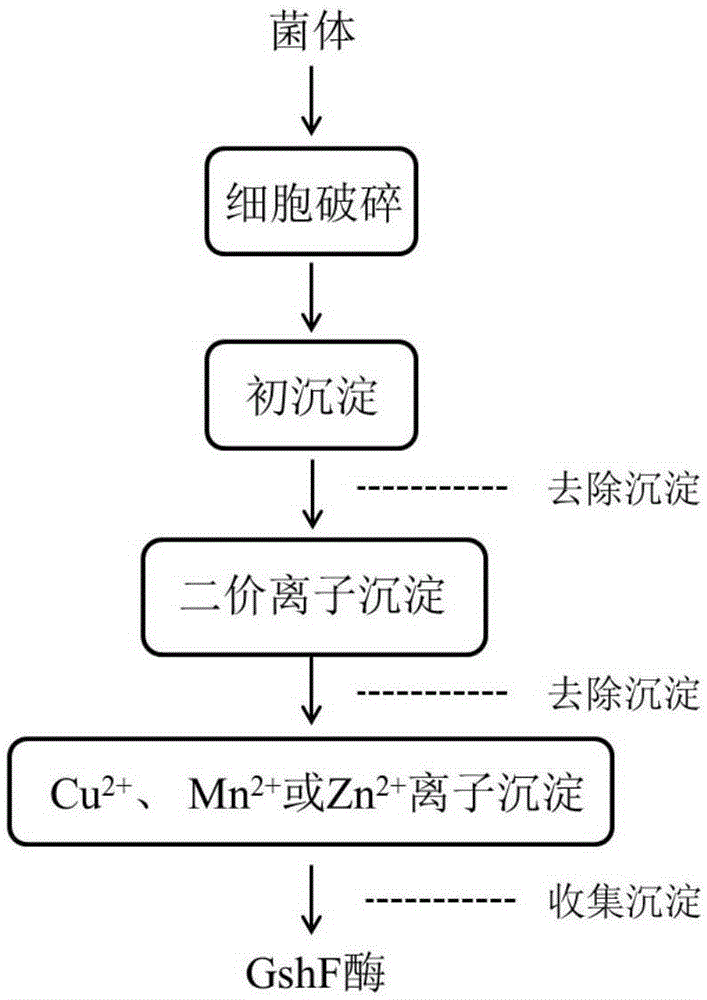

Method used

Image

Examples

Embodiment 1

[0029] (1) Take the thallus containing GshF enzyme and dissolve it in water, the thalline concentration is about 100g / L, and homogeneously crush under high pressure.

[0030] (2) Use hydrochloric acid to adjust the pH value of the crushed enzyme solution to 5.0, place it at 25°C for 30 minutes, then use sodium hydroxide to adjust the pH value of the enzyme solution to 7.0, and centrifuge to remove the precipitate.

[0031] (3) Add 0.05M calcium chloride to the enzyme solution, place it at 4-10°C for 30 minutes, and centrifuge to remove precipitated impurities;

[0032] (4) Finally, adjust the pH to 6.0, then add 0.02M copper chloride, 0.01M manganese chloride and 0.02M zinc sulfate, place at 4-10°C for 30 minutes, and centrifuge to collect the precipitate, which is GshF enzyme.

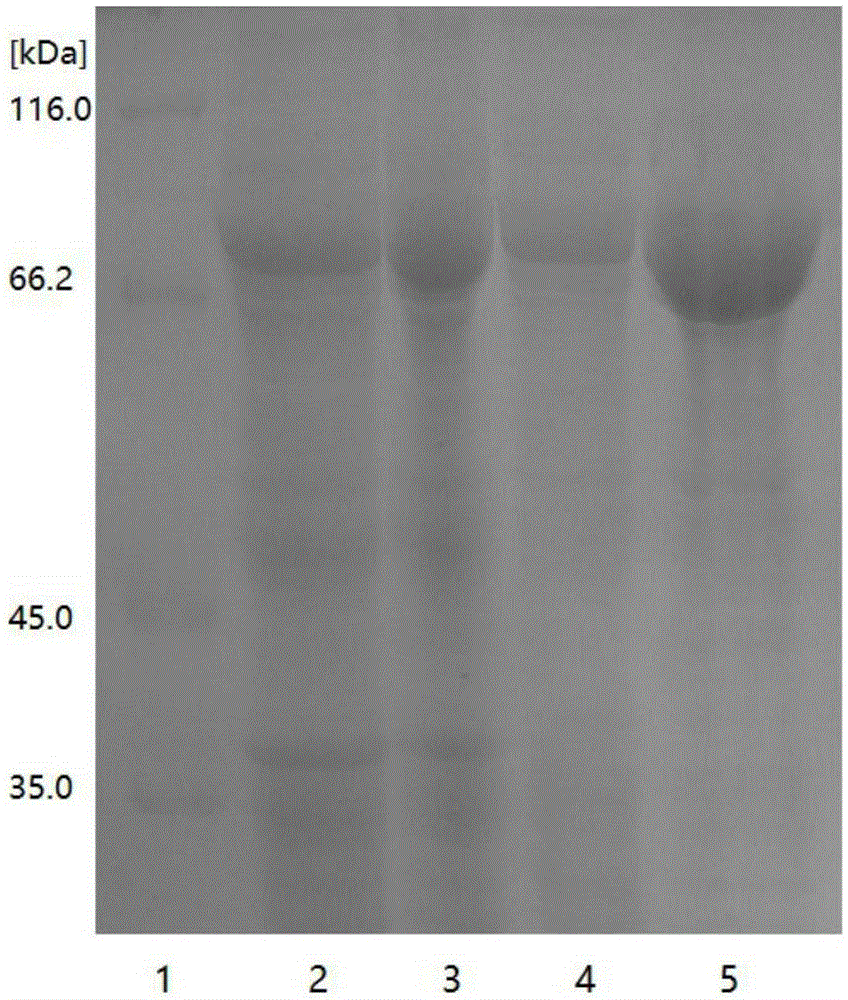

[0033] Dissolve a small amount of purified solid GshF enzyme and prepare a solution of 1 mg / ml. Using the known method for measuring GshF enzyme activity recorded in the prior art, it is detected that...

Embodiment 2

[0035] (1) Take the thallus containing GshF enzyme and dissolve it in water, the thalline concentration is about 100g / L, and homogeneously crush under high pressure.

[0036] (2) Use hydrochloric acid to adjust the pH value of the crushed enzyme solution to 3.0, place it at 4°C for 30 minutes, then use sodium hydroxide to adjust the pH value of the enzyme solution to 7.0, and centrifuge to remove the precipitate.

[0037] (3) Add 0.001M calcium chloride and 0.001M ferrous chloride to the enzyme solution, place it at 4°C for 30 minutes, and centrifuge to remove precipitated impurities;

[0038] (4) Finally, adjust the pH to 4.0, then add 0.005M copper chloride, 0.005M manganese chloride and 0.4M zinc sulfate, leave it at 4°C for 30 minutes, and centrifuge to collect the precipitate, which is GshF enzyme.

[0039] Dissolve a small amount of solid GshF enzyme and prepare a solution of 1 mg / ml. Using the known method for measuring GshF enzyme activity recorded in the prior art, it...

Embodiment 3

[0041] (1) Take the thallus containing GshF enzyme and dissolve it in water, the thalline concentration is about 100g / L, and homogeneously crush under high pressure.

[0042] (2) Use ammonia water to adjust the pH value of the crushed enzyme solution to 9.0, place it at 40°C for 10 minutes, then use phosphoric acid to adjust the pH value of the enzyme solution to 5.0, and centrifuge to remove the precipitate.

[0043] (3) Add 0.5M magnesium chloride to the enzyme solution, place it at 40°C for 10 minutes, and centrifuge to remove precipitated impurities;

[0044] (4) Finally, adjust the pH to 9.0, then add 0.4M copper chloride and 0.005M manganese chloride, place at 40°C for 10 minutes, and centrifuge to collect the precipitate, which is GshF enzyme.

[0045] Dissolve a small amount of solid GshF enzyme and prepare a solution of 1 mg / ml. Using the known method for measuring GshF enzyme activity recorded in the prior art, it is detected that the GshF enzyme activity is about 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com