Method for recovering precious metal from waste circuit boards

A technology of waste circuit boards and precious metals, applied in the field of waste resource utilization, can solve the problems of lead vapor environment and human injury, and achieve the effects of low cost, short process and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

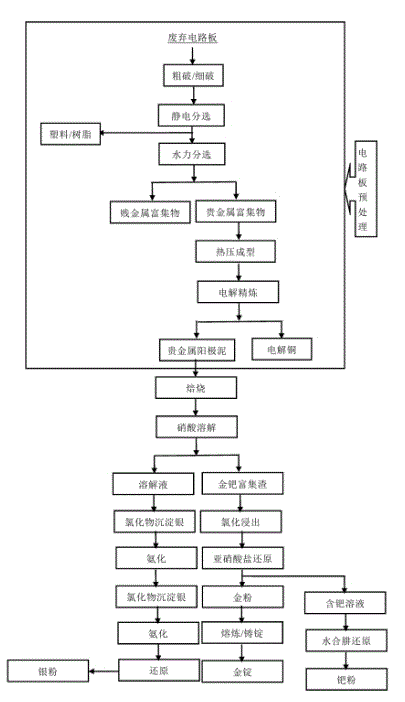

Image

Examples

Embodiment 1

[0022] (1) Circuit board pretreatment. The waste circuit boards are subjected to coarse crushing and fine crushing, then electrostatic separation, and the obtained metal enrichment is subjected to hydraulic separation, and the obtained precious metal enrichment is hot-pressed and electrolytically refined to obtain precious metal anode slime, and then the precious metal anode slime Roasting;

[0023] (2) Silver recovery. The roasted precious metal anode slime is dissolved in 10% nitric acid solution with a mass fraction of 10% according to the solid-to-liquid ratio of 1:4 and dissolved at a temperature of 60°C for 3 hours. After filtering, the solution is added to the solution to precipitate silver ions. The molar ratio is 2.2:1, the temperature of the precipitated silver is 55°C, and the time is 3 hours. The filtered silver chloride is dissolved with 18% ammonia water, the dissolution temperature is 55°C, and the time is 2 hours. The obtained solution is added with hydrazine ...

Embodiment 2

[0029] (1) Circuit board pretreatment. The waste circuit boards are subjected to coarse crushing and fine crushing, then electrostatic separation, and the obtained metal enrichment is subjected to hydraulic separation, and the obtained precious metal enrichment is hot-pressed and electrolytically refined to obtain precious metal anode slime, and then the precious metal anode slime Roasting;

[0030] (2) Silver recovery. The roasted noble metal anode slime is dissolved in 12% nitric acid solution with a mass fraction of 12% according to the solid-to-liquid ratio of 1:4 and dissolved at a temperature of 55°C for 4 hours. After filtering, potassium chloride is added to the solution to precipitate silver ions. The molar ratio is 3:1, the temperature of the precipitated silver is 55°C, and the time is 3 hours. The filtered silver chloride is dissolved with 15% ammonia water, the dissolution temperature is 55°C, and the time is 2.5 hours. The obtained solution is added with zinc po...

Embodiment 3

[0036] (1) Circuit board pretreatment. The waste circuit boards are subjected to coarse crushing and fine crushing, then electrostatic separation, and the obtained metal enrichment is subjected to hydraulic separation, and the obtained precious metal enrichment is hot-pressed and electrolytically refined to obtain precious metal anode slime, and then the precious metal anode slime Roasting;

[0037] (2) Silver recovery. Dissolve the calcined precious metal anode slime in a solid-to-liquid ratio of 1:2.5 by adding a 7.5% nitric acid solution at a temperature of 60°C for 3 hours. After filtering, add calcium chloride to the solution to precipitate silver ions. The molar ratio is 2.5:1, the temperature of the precipitated silver is 65°C, and the time is 3 hours. The filtered silver chloride is dissolved with 17% ammonia water, the dissolution temperature is 50°C, and the time is 3 hours. The obtained solution is added with hydroxylamine hydrochloride The reducing agent is reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com