Gallium nitride diode and manufacturing method thereof

A manufacturing method and diode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced Schottky barrier height, increased leakage, and increased leakage, achieving low turn-on voltage, low Effects of reverse leakage and low on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

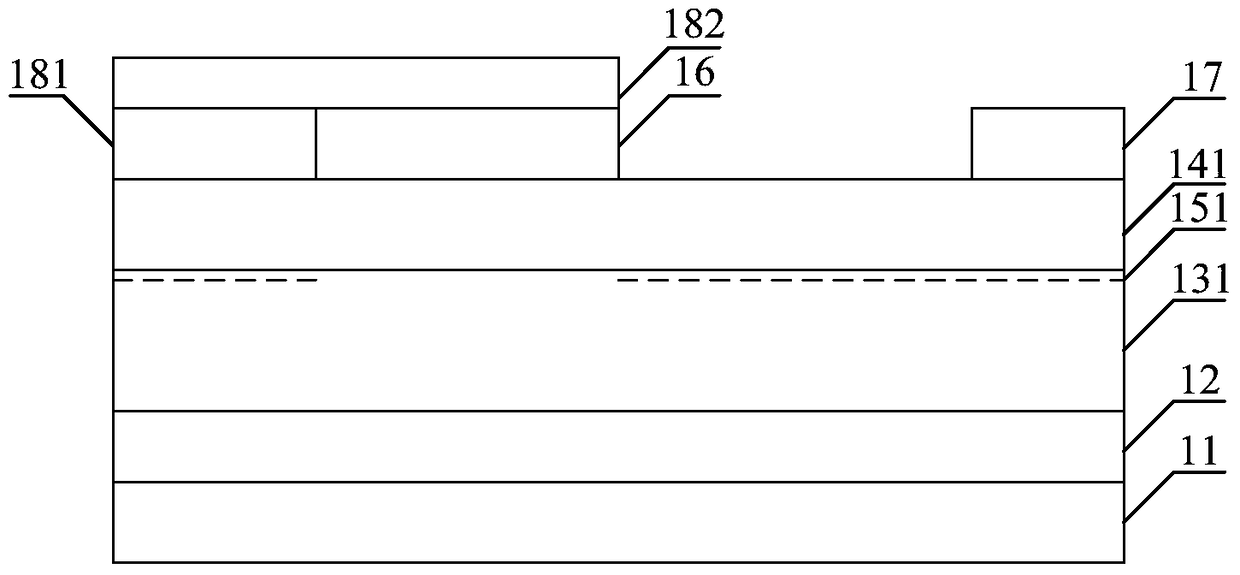

[0059] figure 1 It is a cross-sectional view of the gallium nitride diode provided by the first embodiment of the present invention when the conduction channel is closed. like figure 1 As shown, the gallium nitride diode includes: a substrate 11, a first channel layer 131 located on the substrate 11, a first barrier layer 141 located on the first channel layer 131, the first barrier layer 141 and A first two-dimensional electron gas 151 is formed at the interface of the first channel layer 131, the cap layer structure 16 located on the first barrier layer 141 is located on the first barrier layer 141 on the side of the cap layer structure 16 and / or Or extend to the cathode 17 within the first barrier layer 141, a gap is provided between the cap layer structure 16 and the cathode 17, located on the first barrier layer 141 on the other side of the cap layer structure 16 and / or extend to the first an anode within the barrier layer 141 , and the anode covers the upper surface of...

Embodiment 2

[0093] Figure 6 It is a cross-sectional view when the conduction channel of the gallium nitride diode provided by the second embodiment of the present invention is closed. like Figure 6 As shown, different from the GaN diode provided in Embodiment 1 of the present invention, in the GaN diode provided in Embodiment 2 of the present invention, the surface area of the first barrier layer 141 in contact with the cathode 17 and the first anode 181 Impurities are respectively doped to form doped regions 19 .

[0094] In this embodiment, the impurities may be silicon ions.

[0095] The first barrier layer doped with impurities forms an n-type heavily doped region. Afterwards, when the metal electrode is evaporated in this heavily doped region, due to the high doping concentration of the first barrier layer, the metal electrode and the first barrier layer The barrier width of the first barrier layer is relatively low, and the probability of electron tunneling is high. Therefore...

Embodiment 3

[0101] Figure 9 It is a cross-sectional view when the conduction channel of the gallium nitride diode provided by the third embodiment of the present invention is closed. like Figure 9 As shown, different from the gallium nitride diode provided in Embodiment 1 of the present invention, the gallium nitride diode further includes: a first barrier layer located under the cap layer structure 16 and between the cap layer structure 16 and the cathode 17 The second channel layer 132 on 141, the second barrier layer 142 on the second channel layer 132 between the cap structure 16 and the second channel layer 132 and between the cap structure 16 and the cathode 17, A second two-dimensional electron gas 152 is formed at the interface between the second barrier layer 142 and the second channel layer 132 .

[0102] The second barrier layer 142 and the second channel layer 132 form a heterojunction structure, and a second two-dimensional electron gas 152 is formed at the interface betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com