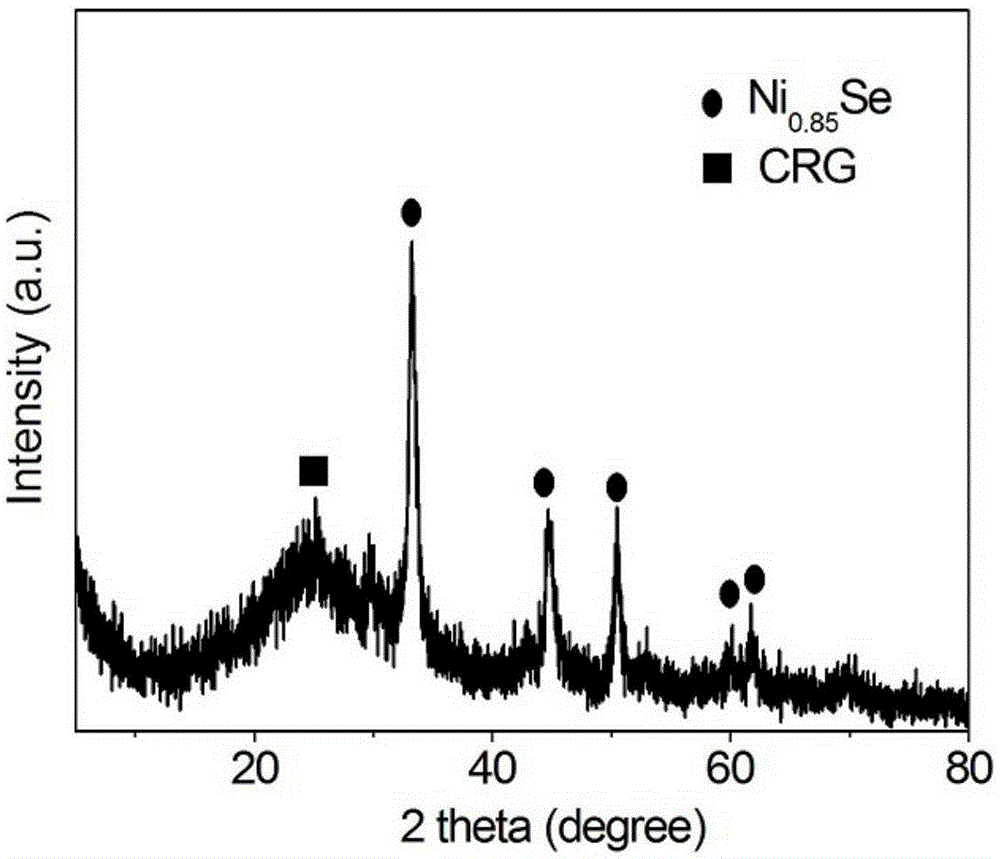

Preparation method of graphene-loaded Ni0.85Se composite material and application thereof

A technology of ni0.85se and composite materials, which is applied in the field of preparation of graphene-loaded Ni0.85Se composite materials, can solve problems such as difficult to meet market demand, low energy density and power density, and achieve high stability, high activity and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) hydrazine hydrate 8mL is mixed with graphene oxide solution, the solvent that described graphene oxide solution adopts is water, and the consumption of corresponding graphene oxide is 550mg, after stirring to form brown solution, add the polytetrafluoroethylene that fills 72mL water Fluorine-lined stainless steel reactor;

[0026] (2) 480mg nickel chloride hexahydrate and 160mg selenium powder are packed into the above-mentioned reaction kettle and fully stirred for 20min;

[0027] (3) Close the reactor and react at 140°C for 24h;

[0028] (4) After the reaction, place it at room temperature for natural cooling, suction filter the mixture in the reactor, and repeatedly wash three times with distilled water and absolute ethanol, and suction filter;

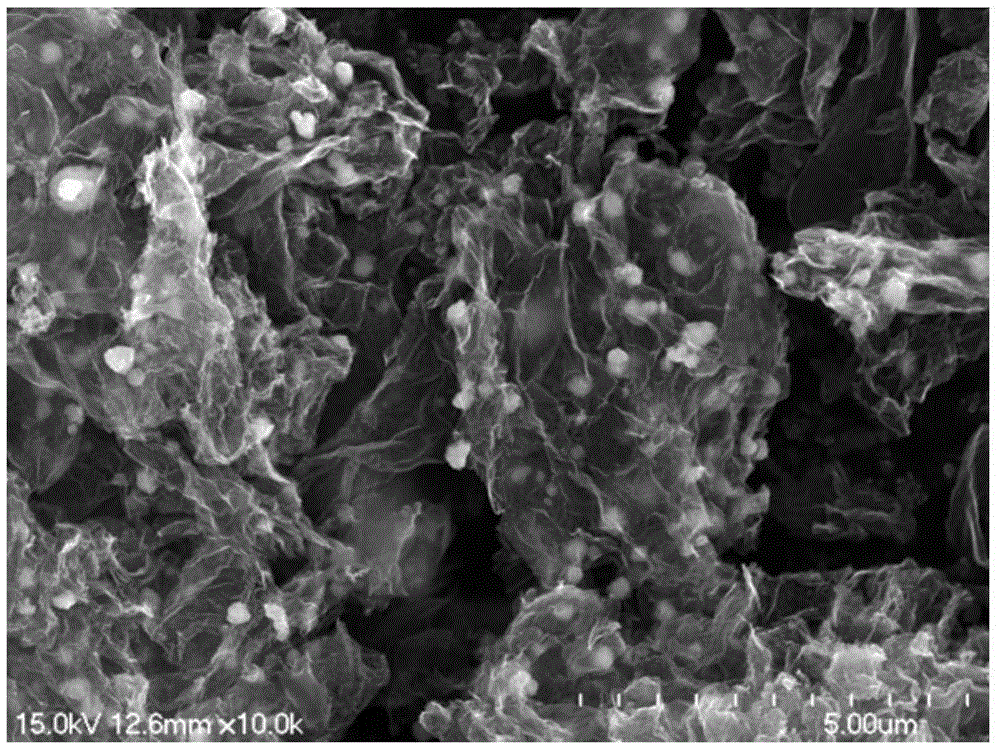

[0029] (5) Finally, the sample was dried under vacuum at 60°C for 12 hours to prepare graphene-loaded Ni 0.85 Se complex

[0030] Material;

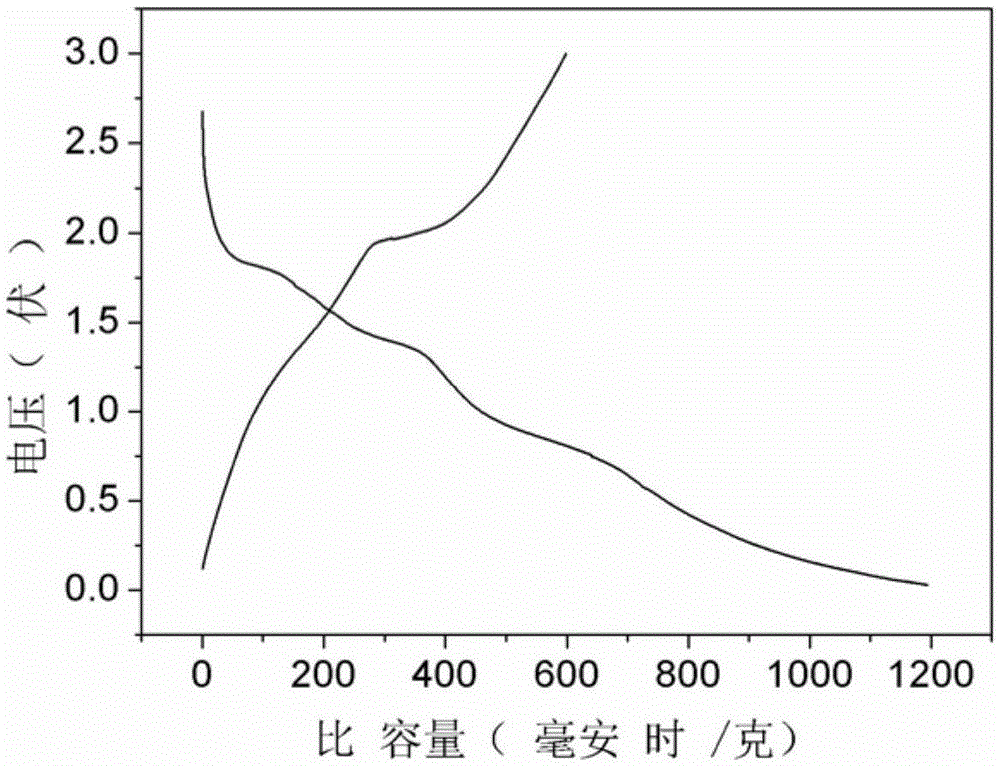

[0031] Performance test: loading Ni on the prepared graphene 0.85 Se comp...

Embodiment 2

[0033] (1) Hydrogen iodide 6mL is mixed with graphene oxide solution, the solvent that described graphene oxide solution adopts is methyl alcohol, and the consumption of corresponding graphene oxide is 500mg, after stirring to form brown solution, add the polysaccharide that fills 70mL water PTFE-lined stainless steel reactor;

[0034] (2) 300mg nickel chloride hexahydrate and 100mg selenium powder are packed into the above-mentioned reaction kettle and fully stirred for 10min;

[0035] (3) Close the reaction kettle and react at 160° C. for 12 hours;

[0036] (4) After the reaction, place it at room temperature for natural cooling, suction filter the mixture in the reactor, and repeatedly wash three times with distilled water and absolute ethanol, and suction filter;

[0037] (5) Finally, the sample was dried under vacuum at 60°C for 12 hours to prepare graphene-loaded Ni 0.85 Se composites.

Embodiment 3

[0039] (1) Ascorbic acid 10mL is mixed with graphene oxide solution, the solvent that described graphene oxide solution adopts is ethanol, and the consumption of corresponding graphene oxide is 700mg, after stirring to form brown solution, add the polytetrafluoroethylene that fills 80mL water Lined stainless steel reactor;

[0040] (2) 550mg nickel chloride hexahydrate and 200mg selenium powder are packed into the above-mentioned reaction kettle and fully stirred for 20min;

[0041] (3) Close the reaction kettle and react at 200°C for 36h;

[0042] (4) After the reaction, place it at room temperature for natural cooling, suction filter the mixture in the reactor, and repeatedly wash three times with distilled water and absolute ethanol, and suction filter;

[0043] (5) Finally, the sample was dried under vacuum at 60°C for 12 hours to prepare graphene-loaded Ni 0.85 Se composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com