Grain continuous drying machine and grain continuous drying method

A grain dryer and dryer technology, which is applied to grain drying technology equipment, grain continuous dryer and grain sustainable drying field, can solve the problems of inconvenient online operation and adjustment, poor measurement accuracy, and large size of drying equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

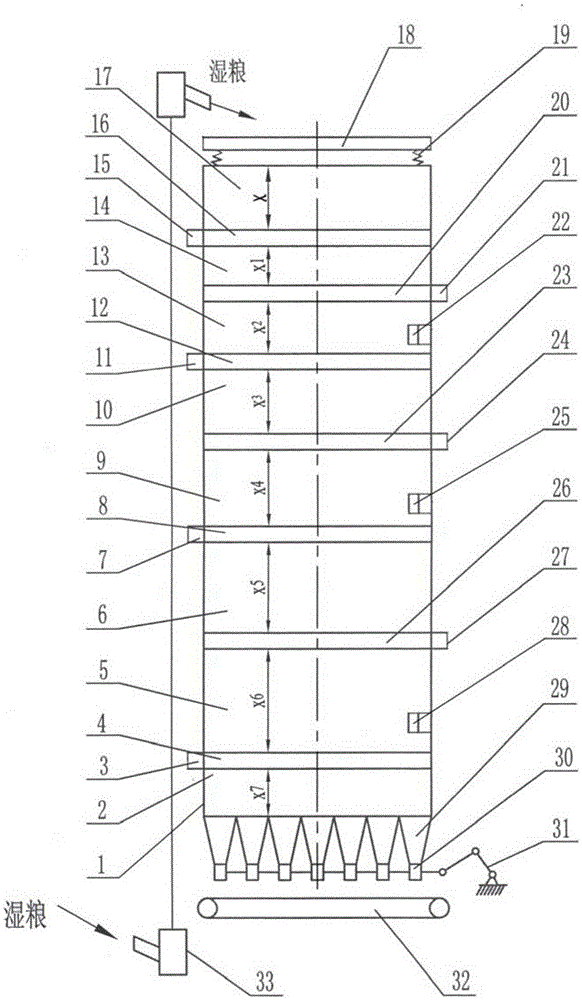

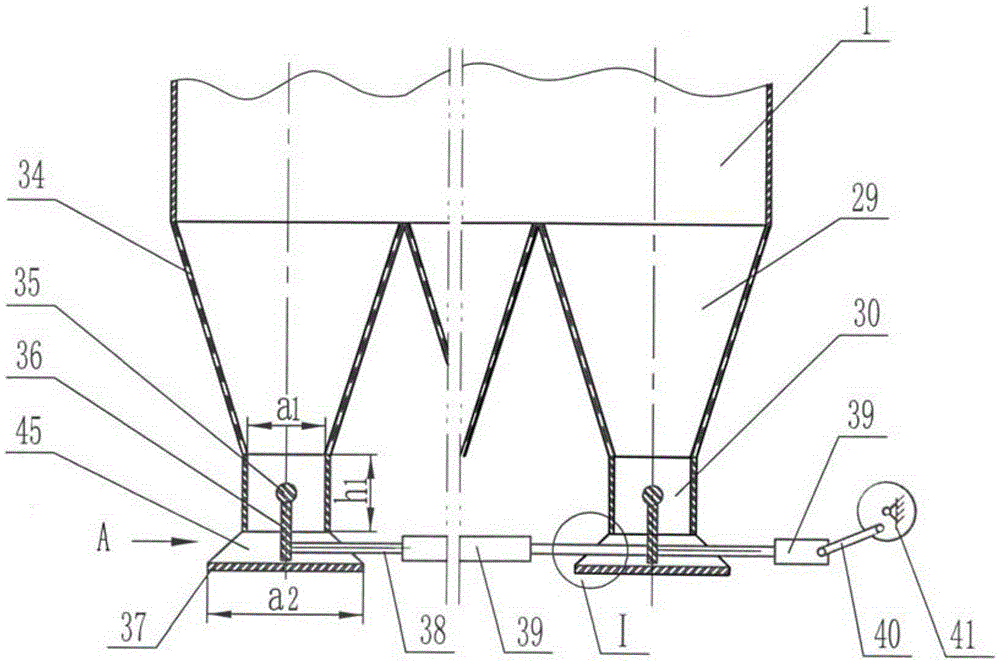

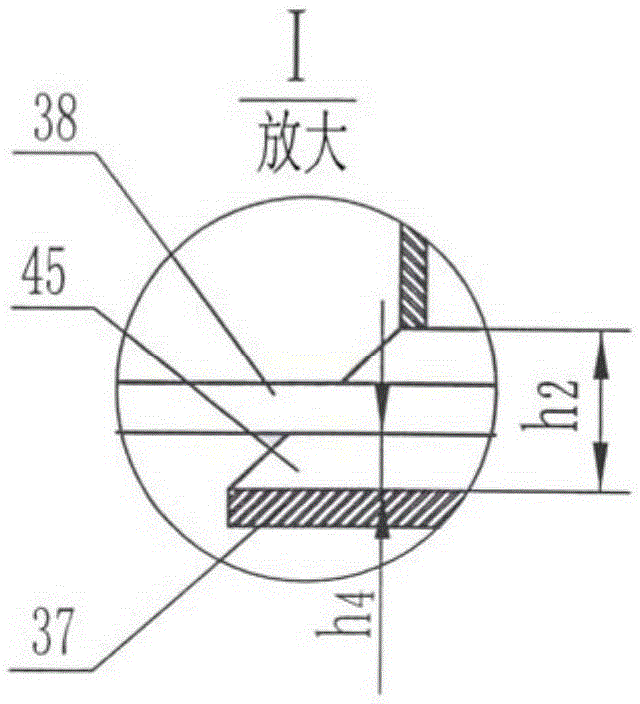

[0062]A continuous drying machine for grain, see attached figure 1 , the grain dryer (1) is a cuboid, mainly composed of a preheating layer, an air inlet layer, an exhaust layer, a distributor, a discharge hopper, a discharge device, a fan, a moisture meter, etc.; its technical characteristics are: dryer Set up from top to bottom: vibrating distributor (18), preheating layer (17), air inlet layer one (16), drying layer one (14), exhaust layer one (20), drying layer two (13), Air intake layer two (12), drying layer three (10), exhaust layer two (23), drying layer four (9), air intake layer three (8), drying layer five (6), exhaust layer three ( 26), drying layer six (5), air inlet layer four (4), drying layer seven (2), discharge hopper (29), discharge nozzle (30) and shaking block discharge control device (31);

[0063] Described vibration distributor (18) is installed on the top of drying machine (1), and vibration distributor (18) is installed on the drying machine (1) with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com