Preparation method of inosine and composition injection thereof

A technology of inosine injection and composition, which is applied in the direction of drug combination, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve the problems of drug safety for patients, loss of production enterprises, yellowing of color, etc. problem, to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

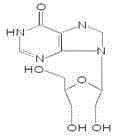

Image

Examples

Embodiment 1

[0073] Accurately weigh the raw and auxiliary materials of each formula with the unit of 1 million ml of water for injection: inosine 6kg, sodium chloride 9kg, glycine 2kg; medicinal activated carbon 0.1kg.

[0074] The preparation process comprises the following steps:

[0075] (1) Take 0.1kg of medicinal activated carbon and make a paste with water for injection.

[0076] (2) Inject 500,000 ml of water for injection into the concentrated preparation tank, add inosine, sodium chloride, and glycine raw materials to stir and dissolve, adjust the pH to 6.5-7.0 with 10% sodium hydroxide solution, and add the adjusted wet medicinal activated carbon Heat to 96°C for 15 minutes.

[0077] (3) After the preparation is completed, the liquid medicine is refluxed and filtered, and the concentrated medicine is filtered using a titanium sintered rod with a pore size not greater than 15 μm for decarburization.

[0078] (4) Use a small beaker to collect the medicinal liquid at the return p...

Embodiment 2

[0087] Accurately weigh the raw and auxiliary materials of each formula with the unit of 1 million ml of water for injection: inosine 6kg, sodium chloride 9kg, glycine 1.5kg; medicinal activated carbon 0.1kg.

[0088] The preparation process comprises the following steps:

[0089] (1) Take 0.1kg of medicinal activated carbon and make a paste with water for injection.

[0090] (2) Inject 500,000 ml of water for injection into the concentrated preparation tank, add inosine, sodium chloride, and glycine raw materials to stir and dissolve, adjust the pH to 6.5-7.0 with 10% sodium hydroxide solution, and add the adjusted wet medicinal activated carbon Heat to 97°C for 15 minutes.

[0091] (3) After the preparation is completed, the liquid medicine is refluxed and filtered, and the concentrated medicine is filtered using a titanium sintered rod with a pore size not greater than 15 μm for decarburization.

[0092] (4) Use a small beaker to collect the medicinal liquid at the return...

Embodiment 3

[0101] Accurately weigh the raw and auxiliary materials of each formula with the unit of 1 million ml of water for injection: inosine 6kg, sodium chloride 9kg, glycine 2.5kg; medicinal activated carbon 0.1kg.

[0102] The preparation process comprises the following steps:

[0103] (1) Take 0.1kg of medicinal activated carbon and make a paste with water for injection.

[0104] (2) Inject 500,000 ml of water for injection into the concentrated preparation tank, add inosine, sodium chloride, and glycine raw materials to stir and dissolve, adjust the pH to 6.5-7.0 with 10% sodium hydroxide solution, and add the adjusted wet medicinal activated carbon Heat to 95°C for 15 minutes.

[0105] (3) After the preparation is completed, the liquid medicine is refluxed and filtered, and the concentrated medicine is filtered using a titanium sintered rod with a pore size not greater than 15 μm for decarburization.

[0106] (4) Use a small beaker to collect the medicinal liquid at the return...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com