Acellular polysaccharide dermal matrix materials and production method and application thereof

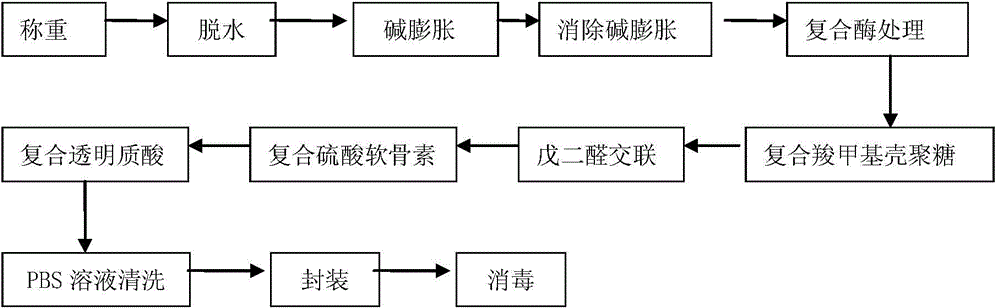

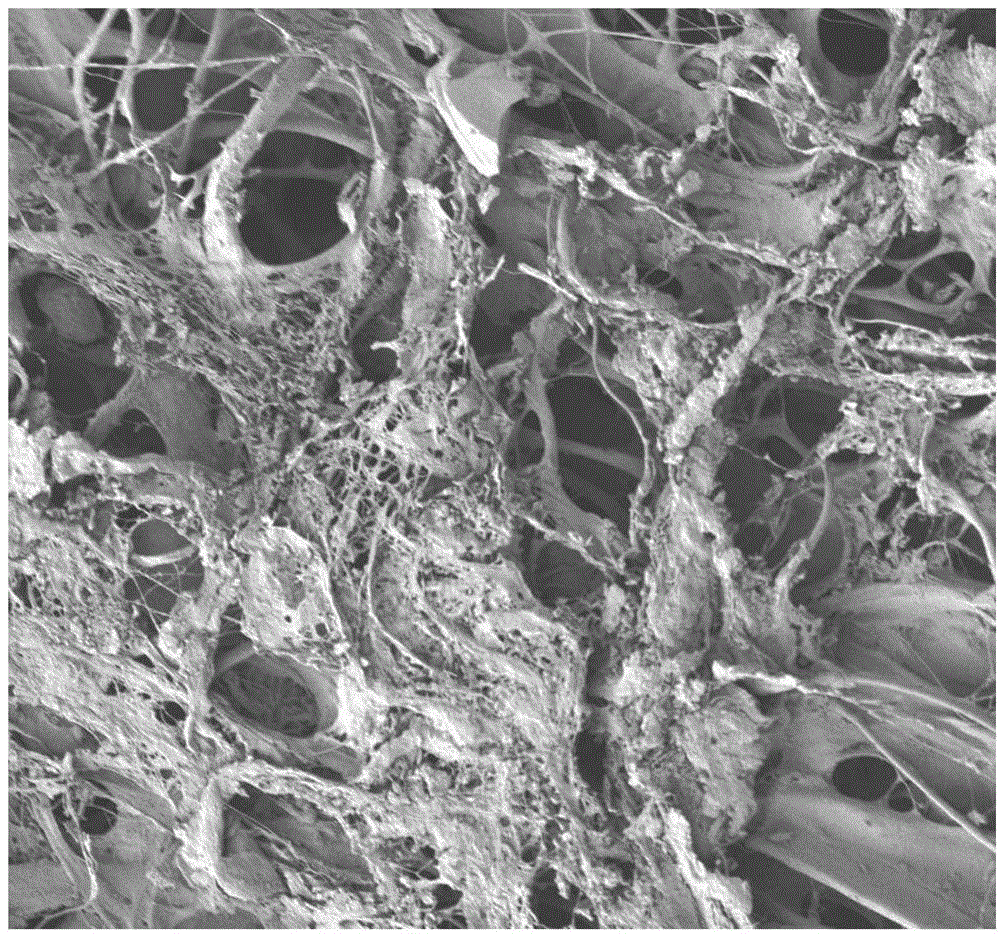

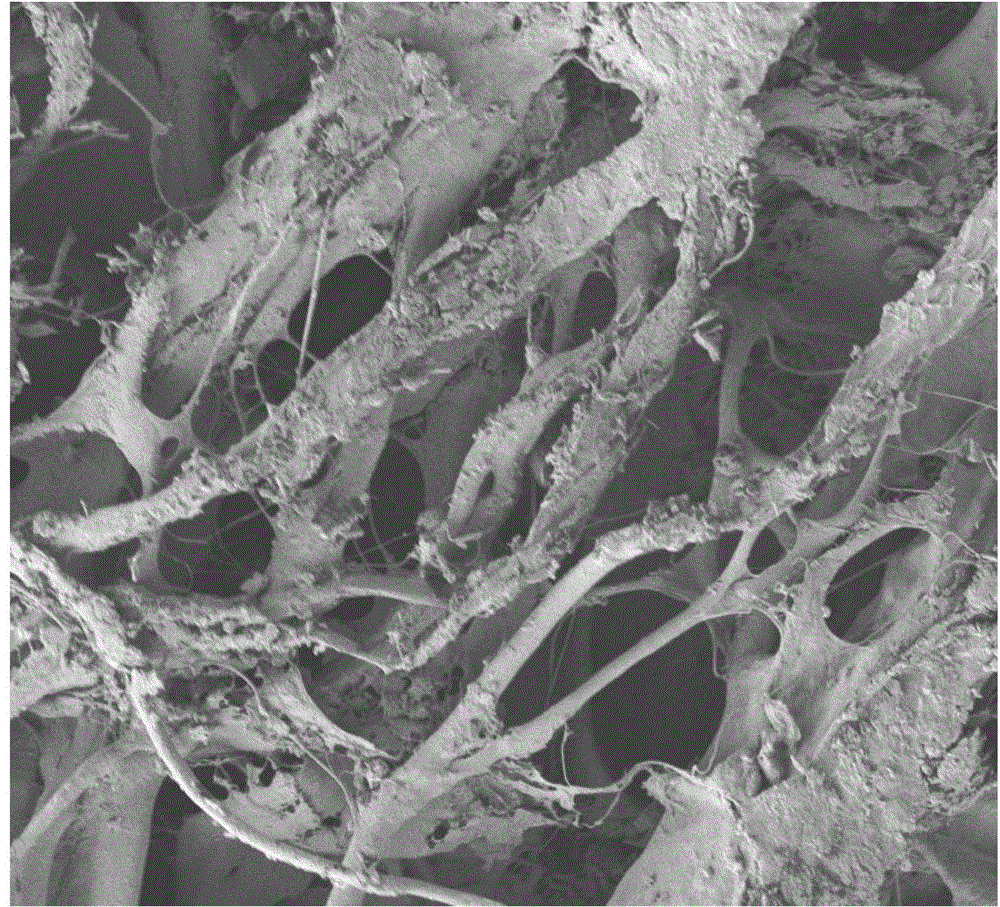

A dermal matrix and cell-free technology, applied in the field of bioengineering, can solve the problems of insufficient antibacterial performance and tensile strength to be improved, and achieve the effect of good water vapor permeability, excellent tensile strength and enhanced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a cell-free polysaccharide dermal matrix dressing, which is prepared by the following steps:

[0032] (1) select porcine acellular dermal matrix (PADM) through sterilized packaging, and accurately weigh as the basis for counting the following procedures;

[0033] (2) Composite carboxymethyl chitosan: Put the prepared acellular dermal matrix into the drum, and add PADM material with a mass ratio of 2.5:1 at a temperature of 40°C and a pH value of 6.0. The mass concentration is 1.00% carboxymethyl chitosan solution, the pH value is adjusted to 5.0 after 30 minutes of reaction, and the pH value is adjusted to 7.0 after another 60 minutes of reaction. Wash the treated material twice with distilled water, 15 minutes each time, and drain the water after washing;

[0034] (3) Glutaraldehyde cross-linking: Add 0.20% glutaraldehyde with a mass ratio of 2.0 to the PADM material under the condition of a temperature of 25°C and a pH va...

Embodiment 2

[0073] This embodiment provides a method for preparing an acellular polysaccharide dermal matrix-epidermal scaffold, which takes the following steps:

[0074] (1) Prepare the acellular polysaccharide dermal matrix material according to the operation of Example 1;

[0075] (2) Composite 5μg / m on the surface of the material 2 growth factor, 10μg / m 2 skin basement membrane formation accelerator, 2.0% glycerin.

[0076] The preparation of the epidermal scaffold by the method can protect the wound, promote the growth of the skin, and improve the healing and regeneration ability of the wound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com