Formate tubular hybrid membrane for arene/alkane separation, and preparation method and application of formate tubular hybrid membrane

A formate and hybrid membrane technology, applied in the field of membrane separation, can solve problems such as stability problems, poor thermal stability, etc., and achieve the effects of good separation effect and stability, improved swelling resistance, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

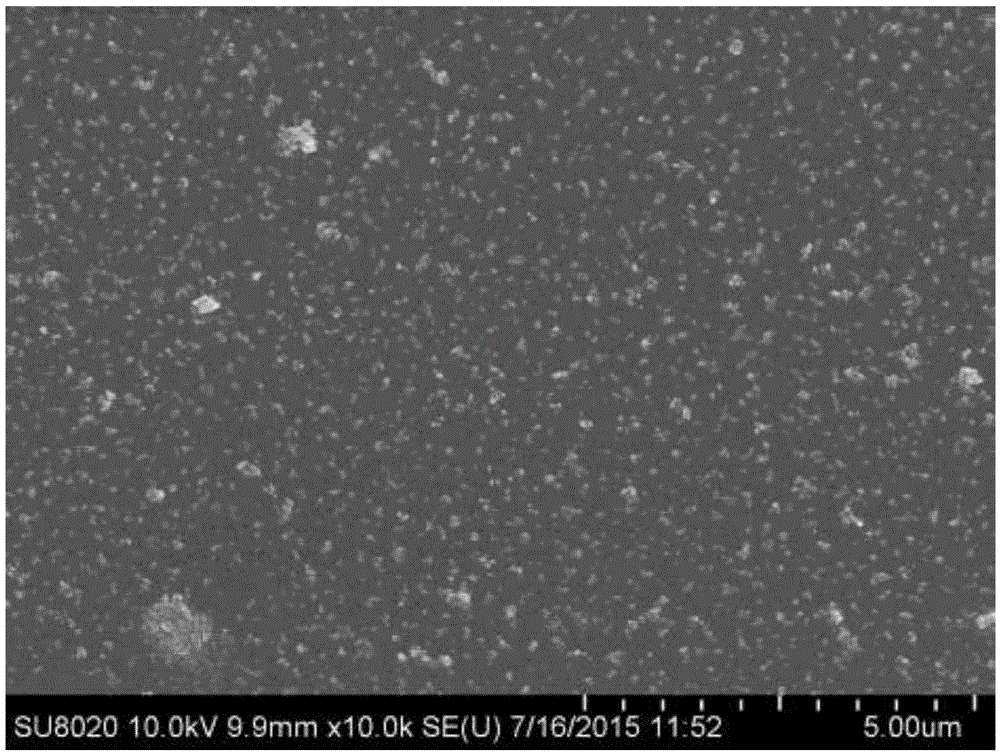

Image

Examples

Embodiment 1

[0030] Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in the pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with amide bonds used is polyether copolyamide (PEBA2533), and the metal source is cobalt carbonate (CoCO 3 , the molecular weight is 118.94), the organic ligand is formic acid (HCOOH, the molecular weight is 46.03), and the solvent of polyether copolyamide is n-butanol.

[0031] Preparation conditions and methods:

[0032] (1) Preparation of Co(HCOO) by solvothermal method 2 2H 2 O. (Weigh 3g of cobalt carbonate and add it to 10ml of water, then add 50ml of formic acid solution dropwise to the above reaction solution, stir and react for 6h while adding dropwise, centrifuge for 1h to obtain the lower layer of precipitation, vacuum dry to obtain pink powdery crystals, fully grind , the particle size is about 3...

Embodiment 2

[0043] Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in the pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with amide bonds used is polyether copolyamide (PEBA2533), and the metal source is cobalt carbonate (CoCO 3 , the molecular weight is 118.94), the organic ligand is formic acid (HCOOH, the molecular weight is 46.03), and the solvent of polyether copolyamide is n-butanol.

[0044] Preparation conditions and methods:

[0045] (1) Preparation of Co(HCOO) by solvothermal method 2 2H 2 O. (weigh 3g of cobalt carbonate and add it to 10ml of water, then add 50ml of formic acid solution dropwise to the above reaction solution, stir and react at room temperature for 6h, centrifuge for 1h to obtain the lower layer of precipitation, vacuum dry to obtain pink powdery crystals, grind, particle size about 300nm.)

[0046]...

Embodiment 3

[0057] Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in the pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with amide bonds used is polyether copolyamide (PEBA2533), and the metal source is cobalt carbonate (CoCO 3 , the molecular weight is 118.94), the organic ligand is formic acid (HCOOH, the molecular weight is 46.03), and the solvent of polyether copolyamide is n-butanol.

[0058] Preparation conditions and methods:

[0059] (1) Preparation of Co(HCOO) by solvothermal method 2 2H 2 O. (weigh 3g of cobalt carbonate and add it to 10ml of water, then add 50ml of formic acid solution dropwise to the above reaction solution, stir and react at room temperature for 6h, centrifuge for 1h to obtain the lower layer of precipitation, vacuum dry to obtain pink powdery crystals, grind, particle size about 300nm.)

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Upstream pressure | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com