Surface amination nanometer ferroferric oxide adsorbent and preparation method thereof

A technology of triiron tetroxide and surface amination, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc. Magnetic separation, good adsorption, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the surface aminated nanometer ferric oxide adsorbent provided in this embodiment comprises the following steps:

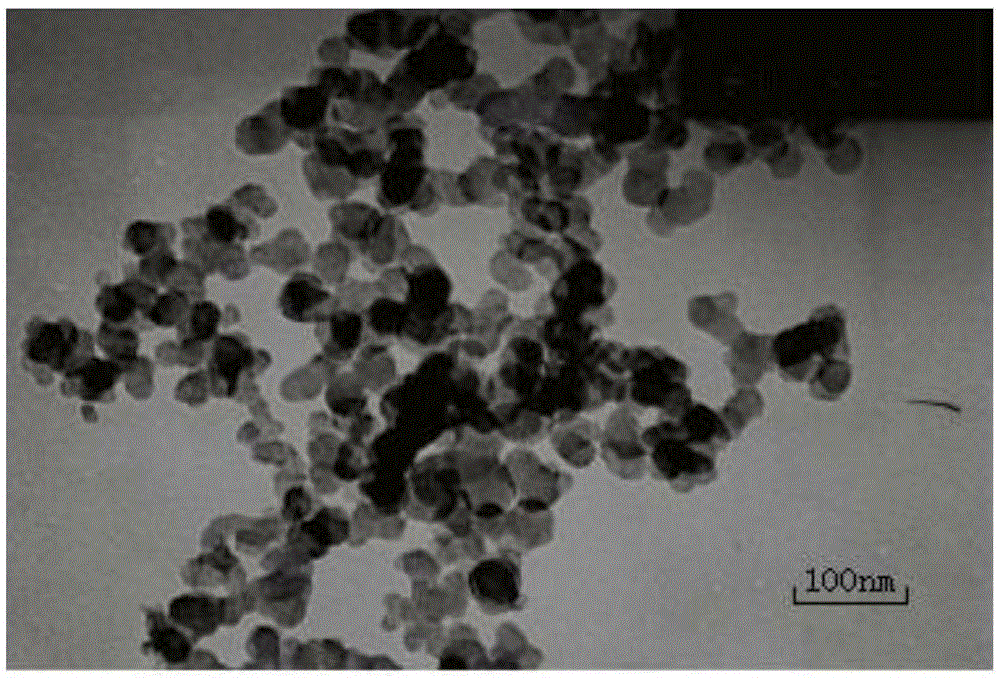

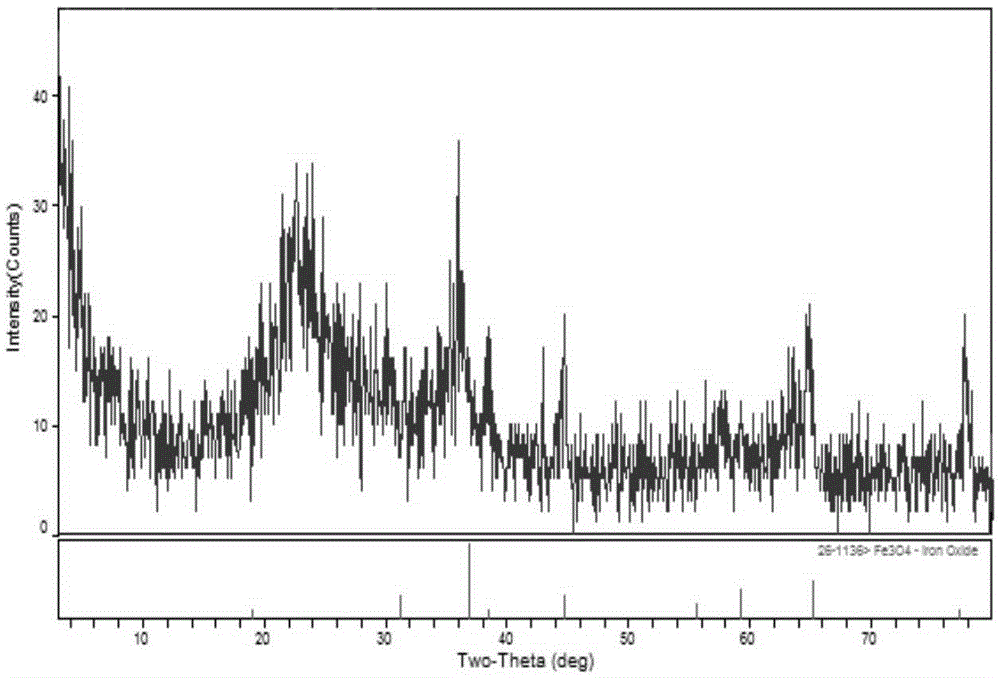

[0028] (1) Magnetic Nano Fe 3 o 4 Particle preparation

[0029] 1.59gFeCl 2 4H 2 O (0.008mol) and 3.78g FeCl 3 ·6H 2 O (0.014mol) was dissolved in 140mL of distilled water and mixed evenly; under mechanical stirring, 20mL of 3.5mol / L NaOH solution was added to the mixed solution, and after stirring for 30 minutes, the precipitate was magnetically separated to obtain nano-Fe 3 o 4 particle;

[0030] (2) Preparation of surface aminated nano-ferric oxide adsorbent

[0031] 1) The prepared nano-Fe 3 o 4 Particles were added to the ethanol solution prepared by mixing 64mL distilled water and 200mL ethanol, and after ultrasonic treatment for 10 minutes, press nano-Fe 3 o 4 The molar ratio of particles to TEOS is 1:8, add TEOS, and continue to sonicate for 10 minutes;

[0032] 2) Under mechanical stirring, add NH 3 ·H 2 0, ...

Embodiment 2

[0035] The preparation method of the surface aminated nanometer ferric oxide adsorbent provided in this embodiment comprises the following steps:

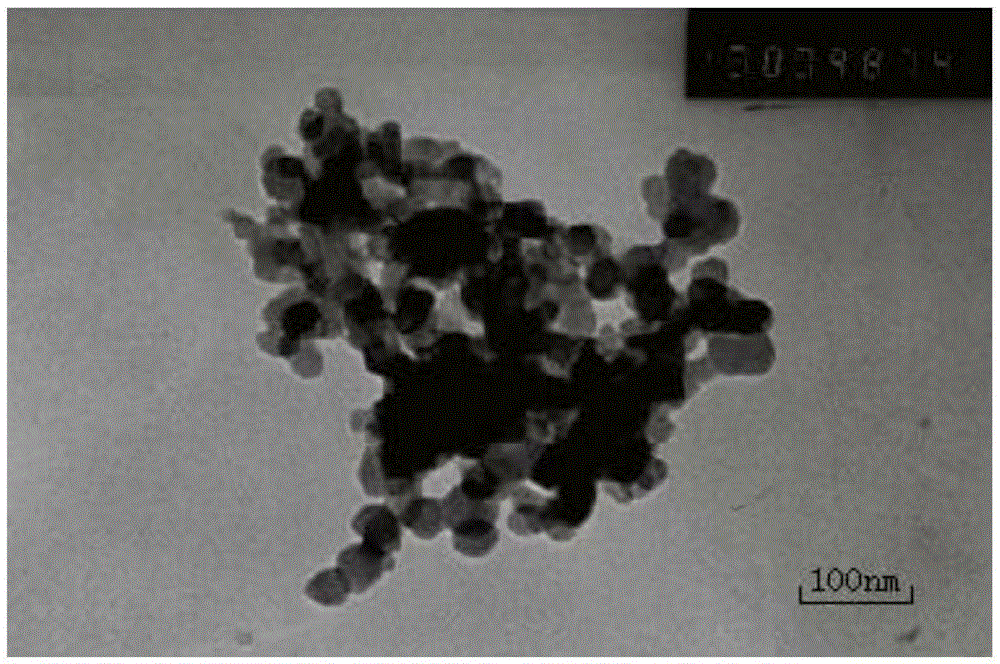

[0036] (1) Magnetic Nano Fe 3 o 4 Particle preparation

[0037] 1.59gFeCl 2 4H 2 O (0.008mol) and 4.31gFeCl 3 ·6H 2 O (0.016mol) was dissolved in 140mL of distilled water and mixed evenly; under mechanical stirring, 20mL of 3.5mol / L NaOH solution was added to the mixed solution, and after stirring for 50 minutes, the precipitate was magnetically separated to obtain nano-Fe 3 o 4 particle;

[0038] (2) Preparation of surface aminated nano-ferric oxide adsorbent

[0039] 1) The prepared nano-Fe 3 o 4 Particles were added to the ethanol solution prepared by mixing 60mL distilled water and 300mL ethanol, and after ultrasonic treatment for 30 minutes, press nano-Fe 3 o 4 The molar ratio of particles to TEOS is 1:10, add TEOS, and continue to sonicate for 30 minutes;

[0040] 2) Under mechanical stirring, add NH 3 ·H 2 0, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com