Method for preparing porous flake-like graphite phase carbon nitride on large scale, and application thereof

A phase carbon nitride and flake graphite technology, applied in the field of porous flake graphite phase carbon nitride, to achieve the effect of strong controllability, strong ability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

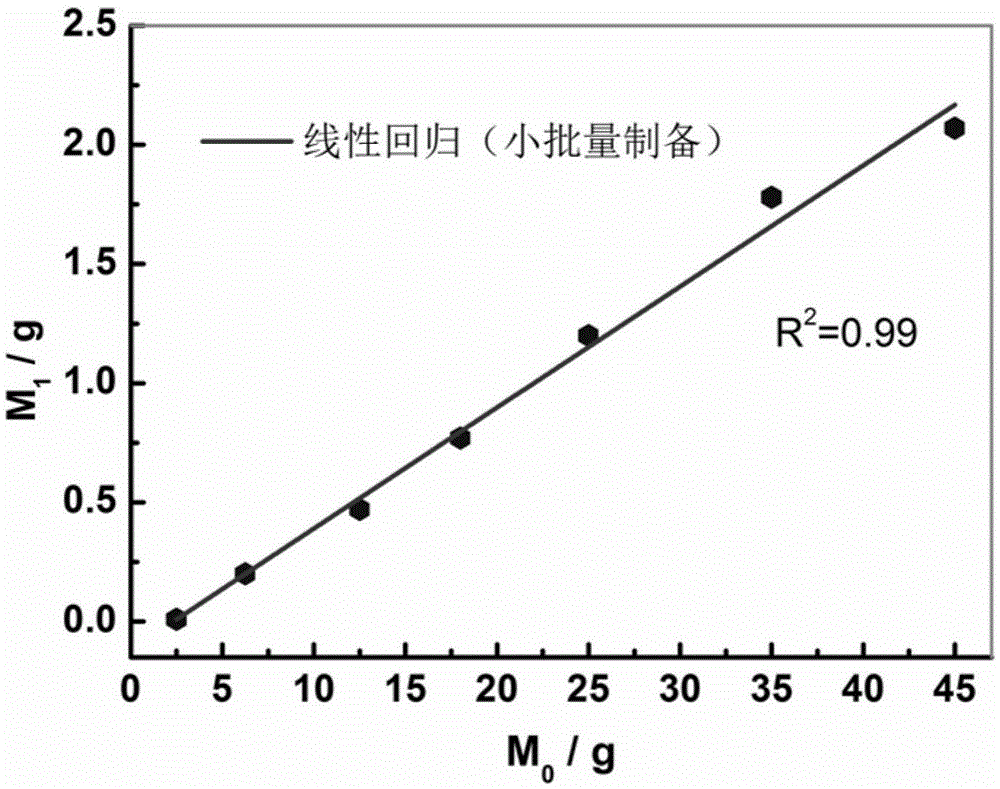

[0025] 1) Preparation of porous flake g-C in small batches 3 N 4 : In a small volume reactor, take different quality urea (M 0 =2.5g, 6.25g, 12.5g, 18g, 25g, 35g, 45g), heat up to 600°C at a heating rate of 3°C per minute, calcinate for 2 hours, and cool down to room temperature naturally. Disperse the obtained powder in an appropriate amount of ethanol, ultrasonically treat it for 30 minutes, and dry it quickly at 70°C and -0.1MPa vacuum to obtain the desired porous sheet g-C 3 N 4 (weigh the corresponding weight M 1 ).

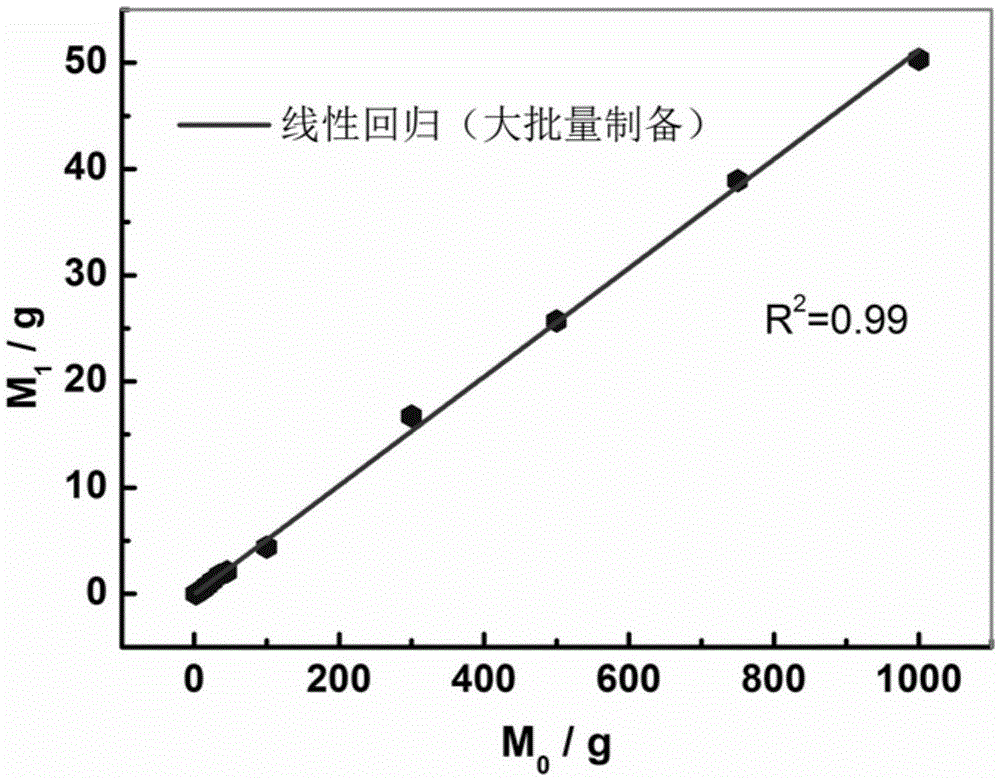

[0026] 2) Large-scale preparation of porous sheet-like g-C 3 N 4 : In large-volume reactors, expand the scale of preparation and increase the amount of urea input (M 0 =100g, 300g, 500g, 750g, 1000g), heated up to 600°C at a heating rate of 3°C per minute, calcined for 2 hours, and cooled down to room temperature naturally. Disperse the obtained powder in an appropriate amount of ethanol, ultrasonically treat it for 30 minutes, and dry it quickly at ...

Embodiment 2

[0031] The preparation concentration is 2.5×10 -5 The rhodamine B solution of mol / L uses the porous flake graphite phase carbon nitride prepared in embodiment 1 (1) and (2) respectively, gets 10mg and joins in the 60mL degradant solution, stirs 30min to make the target degradant in The surface of the photocatalyst reached adsorption-desorption equilibrium, during which samples were taken and analyzed every 10 minutes. Afterwards, the solution was illuminated (300W xenon lamp, visible light, wavelength 420nm<λ<780nm), and samples were taken and analyzed at intervals of 5 minutes to observe the concentration change of the target degradation product in the solution.

[0032] Such as Figure 4, it can be seen that the porous sheet-like g-C prepared in large batches and small batches 3 N 4 The photocatalytic activity is not much different, and Rhodamine B can be completely decomposed within 25 minutes.

[0033] Figure 5 The UV-Vis absorption spectrum during the degradation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com