Flaky porous nanometer zinc oxide and preparation method thereof

A nano-zinc oxide, flake technology, applied in the field of nano-zinc oxide preparation, to achieve the effect of simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

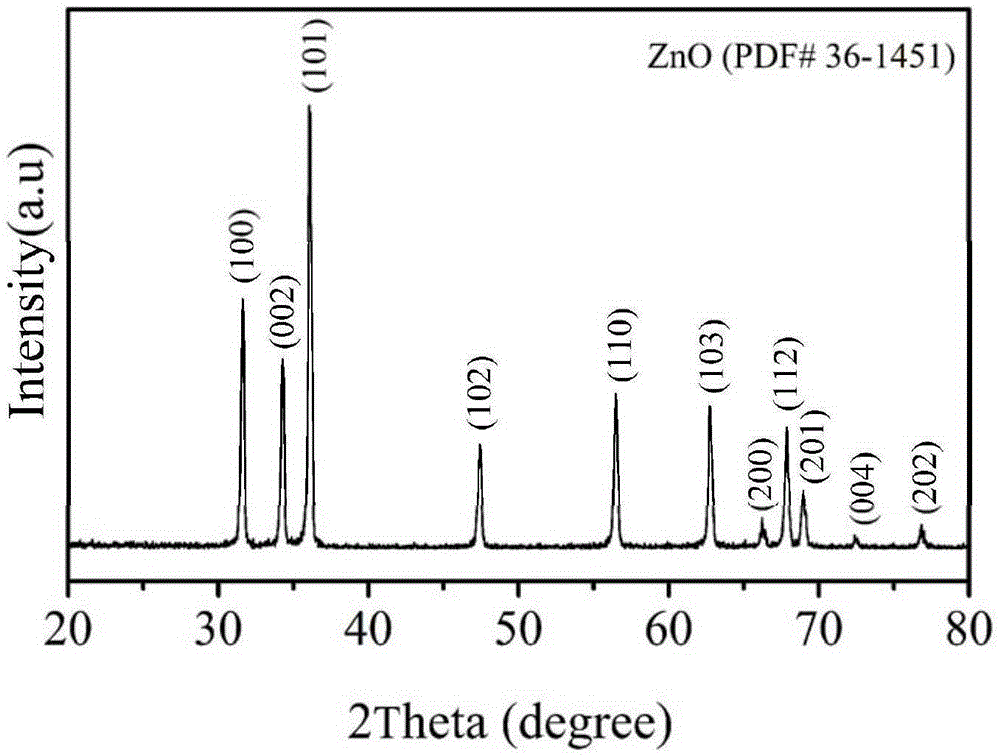

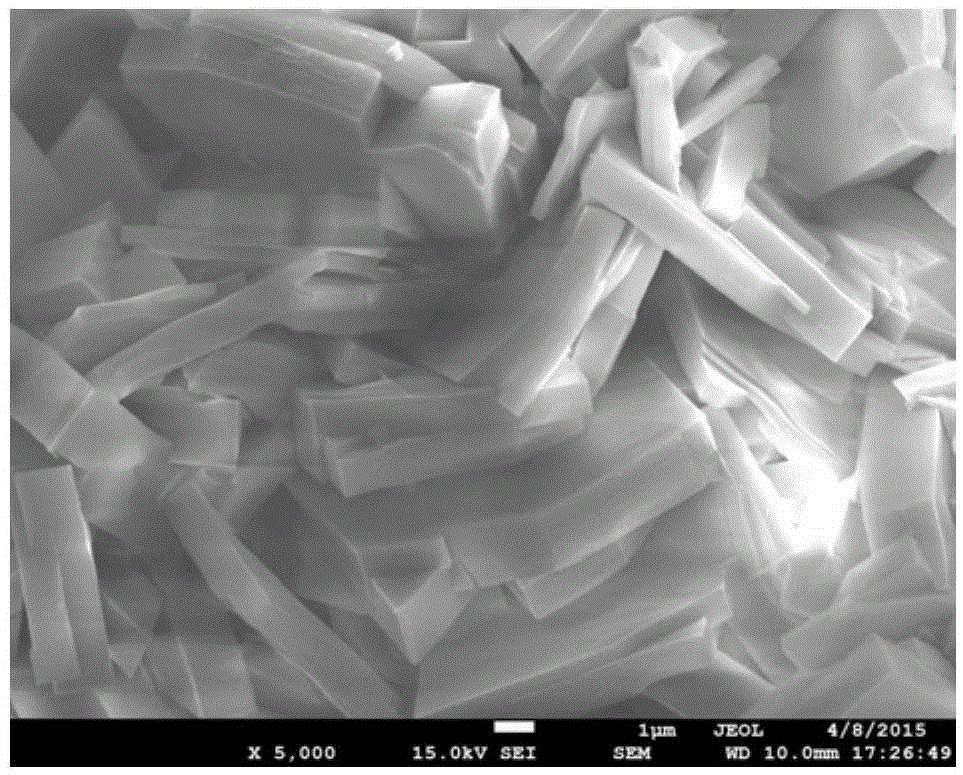

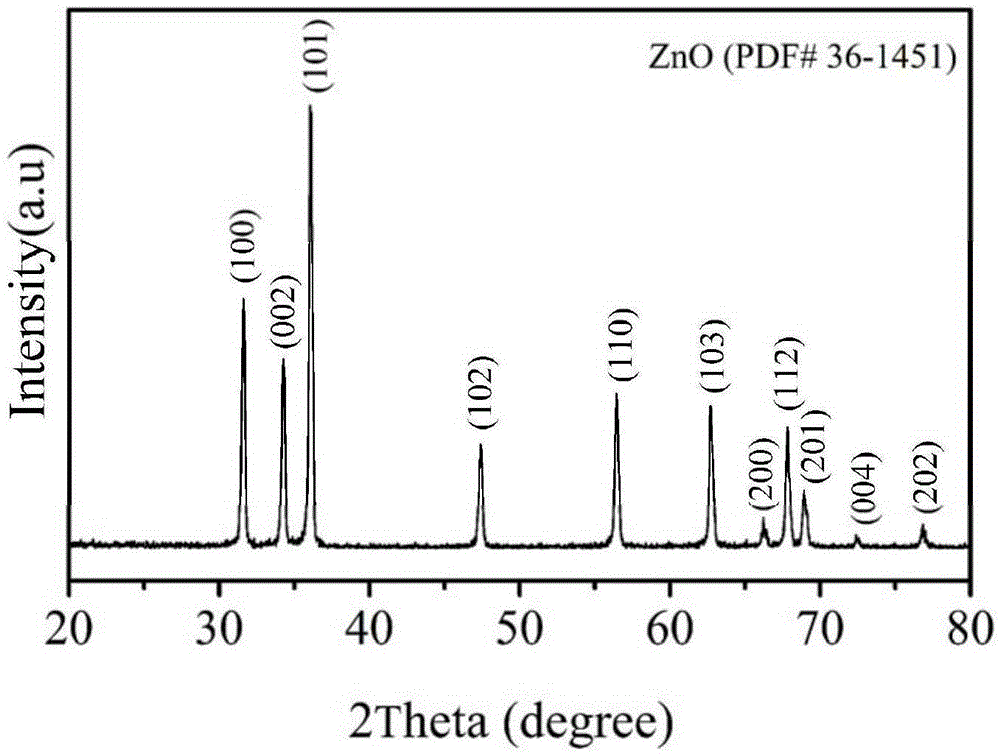

[0033] Sheet-shaped porous nano-zinc oxide, using zinc acetate and urea as reaction raw materials, first hydrothermally reacting under the action of sodium citrate to generate precursor zinc carbonate, and calcining zinc carbonate at a temperature of 600°C for 2 hours to obtain nano-zinc oxide.

[0034] Concrete preparation steps are as follows:

[0035] Precursor ZnCO 3 preparation of

[0036] 1) Add zinc acetate and urea to water, stir at room temperature for 10 minutes and mix well to obtain solution A;

[0037] The concentration of zinc acetate in solution A is 0.033mol / L, and the concentration of urea is 0.05mol / L;

[0038] 2) Add 0.3g of sodium citrate to 40mL of solution A, stir at room temperature for 30 minutes to obtain solution B;

[0039] 3) Move the solution B into a stainless steel reaction kettle, heat it to a temperature of 110°C, and keep it warm for 5 hours. After the reaction is completed, filter and separate the ZnCO 3 , washed with ethanol and deionize...

Embodiment 2

[0044] Sheet-shaped porous nano-zinc oxide, using zinc sulfate and urea as reaction raw materials, first hydrothermally reacting under the action of sodium citrate to generate precursor zinc carbonate, and calcining zinc carbonate at a temperature of 600°C for 1.5 hours to obtain nano-zinc oxide.

[0045] Concrete preparation steps are as follows:

[0046] Precursor ZnCO 3 preparation of

[0047] 1) Add zinc sulfate and urea to water, stir at room temperature for 15 minutes and mix well to obtain solution A;

[0048] The concentration of zinc sulfate in solution A is 0.067mol / L, and the concentration of urea is 0.1mol / L;

[0049] 2) Add 0.6 g of sodium citrate to 40 mL of solution A, stir at room temperature for 25 minutes and mix well to obtain solution B;

[0050] 3) Move the solution B into a stainless steel reaction kettle, heat it to a temperature of 110°C, and keep it warm for 5 hours. After the reaction is completed, filter and separate the ZnCO 3 , washed with etha...

Embodiment 3

[0054] Sheet-shaped porous nano-zinc oxide, using zinc chloride and urea as reaction raw materials, first hydrothermally reacted under the action of sodium citrate to generate precursor zinc carbonate, and the zinc carbonate was calcined at a temperature of 400°C for 2.5 hours to obtain nano-zinc oxide.

[0055] Concrete preparation steps are as follows:

[0056] Precursor ZnCO 3 preparation of

[0057] 1) Add zinc chloride and urea to water, stir at room temperature for 5 minutes and mix well to obtain solution A;

[0058] The concentration of zinc chloride in solution A is 0.033mol / L, and the concentration of urea is 0.05mol / L;

[0059] 2) Add 0.3 g of sodium citrate to 40 mL of solution A, and stir at room temperature for 35 minutes to obtain solution B;

[0060] 3) Move the solution B into a stainless steel reaction kettle, heat it to a temperature of 70°C, and keep it warm for 5 hours. After the reaction is completed, filter and separate the ZnCO 3 , washed with ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com