Preparation method of lithium molybdate

A technology of lithium molybdate and molybdic acid, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of unclean purification and fine particles of molybdate, and achieve low production cost, simple process and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of a kind of lithium molybdate of the present invention is described in further detail below.

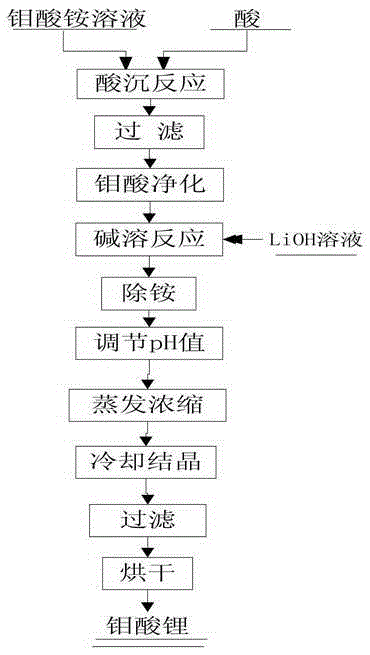

[0024] A kind of preparation method of lithium molybdate of the present invention comprises following technological process:

[0025] A. Ingredients: Add pure water or centrifuged mother liquor and ammonium molybdate solid to the batching kettle, the liquid-solid ratio (wt%) is 2:1~6:1, stir for 30~60min to get ammonium molybdate solution;

[0026] B. Acid precipitation reaction: Add 50-100L pure water and 0.1-0.5kg molybdic acid powder into the reaction kettle, raise the temperature to 60-100°C, stir for 0.5-2h, control the pH of the solution to 0.1-3, and then pour it into the reaction kettle Add ammonium molybdate and inorganic acid dropwise at the same time, the dropping rate is 100~500L / h, and stir for 30~60min;

[0027] C. Purification of molybdenum acid: Wash the molybdenum acid slurry obtained in step B with inorganic acid and pure water succes...

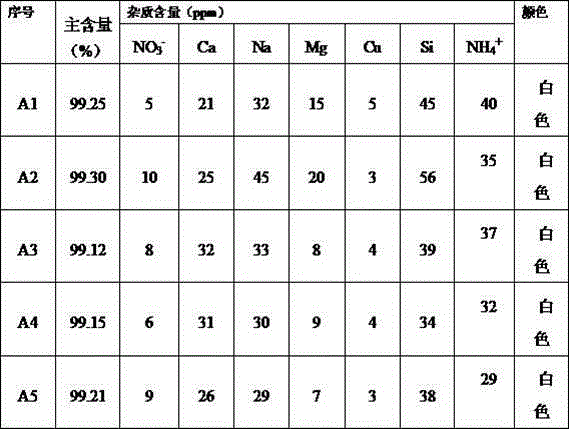

Embodiment 1

[0037] A. Take by weighing 150kg ammonium molybdate and join in the batching kettle, add 900L pure water, stir 60min, obtain 1050Kg ammonium molybdate solution;

[0038] B. Add 100L pure water and 0.5kg molybdenum acid powder into the reaction kettle as the bottom liquid and seed crystal, raise the temperature to 100°C, stir for 2 hours, control the pH of the solution to 3, and then add the ammonium molybdate solution prepared in step A dropwise at the same time and 10mol / L of sulfuric acid solution into the reactor, the rate of addition is 500L / h, stirring and reacting for 60min;

[0039] C. the molybdic acid slurry obtained in step B is washed with 10mol / L sulfuric acid and pure water successively, and the sulfuric acid washing is carried out at normal temperature, and the pure water washing temperature is 100 ° C, washed 5 times, and centrifuged to obtain 23Kg molybdic acid ;

[0040] D. Add the molybdenum acid obtained in step C and 138L of pure water according to the rat...

Embodiment 2

[0046] A. Take by weighing 100kg ammonium molybdate and join in the batching kettle, add 400L centrifuge mother liquor, stir 30min, obtain 500Kg ammonium molybdate solution;

[0047] B. Add 50L of pure water and 0.1kg of molybdic acid powder into the reaction kettle as the bottom liquid and seed crystal, raise the temperature to 60°C, stir for 0.5h, control the pH of the solution to 0.1, and then add the ammonium molybdate prepared in step A dropwise at the same time Solution and the sulfuric acid solution of 3mol / L are in the reactor, and the rate of addition is 100L / h;

[0048] C. the molybdic acid slurry obtained in step B is washed with 3mol / L sulfuric acid and pure water successively, and the sulfuric acid washing is carried out at normal temperature, and the pure water washing temperature is 30 ° C, washed twice, and centrifuged to obtain 15Kg molybdic acid ;

[0049] D. Add the molybdenic acid obtained in step C and 30L of pure water (calculated according to the ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com