Ecological floating bed for remediation of oil-polluted water bodies

A water body remediation, ecological floating bed technology, applied in water pollutants, biological water/sewage treatment, water/sludge/sewage treatment, etc. The wide application of materials can achieve the effect of strong adsorption performance, good visible light activity, enhanced adsorption degradation performance and purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

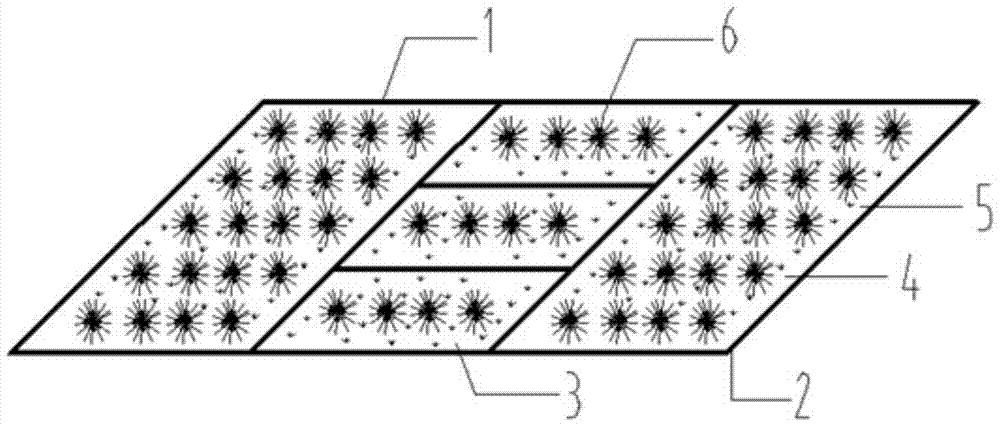

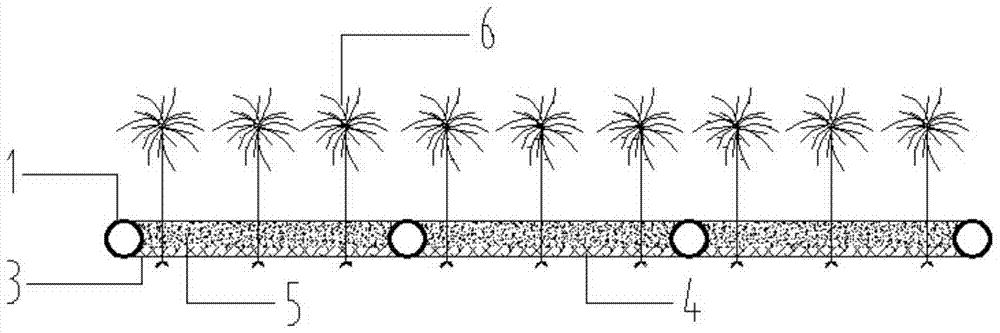

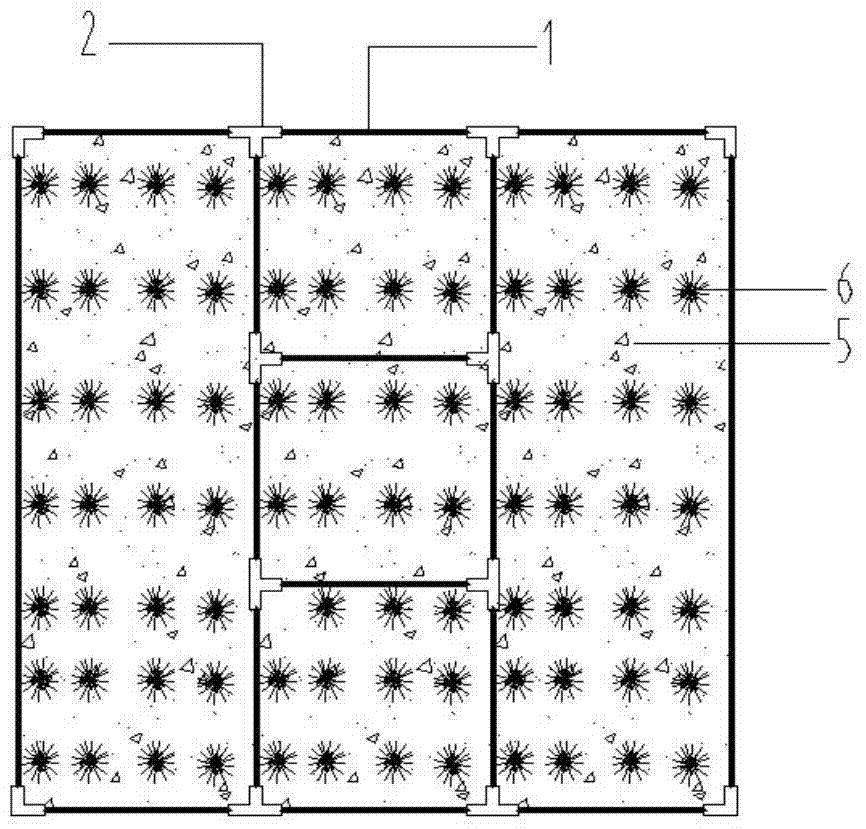

[0039] An ecological floating bed for remediation of oil-polluted water prepared based on waste materials, comprising: a main frame 1, a PVC casing joint 2, a non-woven fabric 3, a bottom filling material 4, an upper filling material 5, and the Agricultural plants6.

[0040] The main frame is made of 6 casing supports with a length of 0.9m, 2 casing supports with a length of 0.3m, 4 DN15 right-angle two-way joints, and 8 DN15 positive tee joints. The casing supports are made of waste polyurethane foam Plastic loaded with TiO infiltrated with a certain amount of N element 2 The material is prefabricated. refer to Figure 1 to Figure 3 Assembled, the interface is sealed with a small amount of silicone.

[0041] The production process of the main frame is as follows: take 300g of waste polyurethane foam, use a small molecule alkyl glycol as an alcoholysis agent, and react for 2 hours at 200°C to obtain a polyether polyol; 20mL of tetrabutyl titanate Add the ester to 10mL of a...

Embodiment example 2

[0046] The production process of this case refers to the implementation case 1, but there are the following differences: the main frame is assembled by six 0.3m and two 0.1m casing brackets, and the casing bracket production process has the following differences: Take 100g of waste polyurethane foam plastics to obtain polyether polyols; add 6 mL of tetrabutyl titanate to 3 mL of absolute ethanol under vigorous stirring, stir for 30 min, then add dropwise 1.5 mL of concentrated nitric acid, 2 mL of twice distilled water and 25 mL of absolute ethanol Mix the solution to make TiO 2 dry gel. urea and TiO 2 Xerogels were mixed and ground at different mass ratios of 3:1 to prepare N-doped TiO 2 Nanoparticles. 8 g of N-doped TiO 2 Particles, mixed with 80g of diphenylmethylpropane diisocyanate, heated in a water bath at 40°C to form a liquid; mixed 15g of dichloromethane with 80g of polyether polyol, heated in a 60°C water bath and continuously stirred to form a liquid B; Liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com