Flashing optical fiber panel and preparation method

A scintillation fiber and panel technology, applied in optics, photographic technology, X-ray/infrared technology, etc., can solve the problems of difficult to enlarge the size of photomultiplier tube and CCD device, low resolution, slow crystal growth, etc., to overcome the detection Efficiency and resolution restrict each other, high energy resolution, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method of flashing optical fiber panel provided by the present invention comprises the following steps:

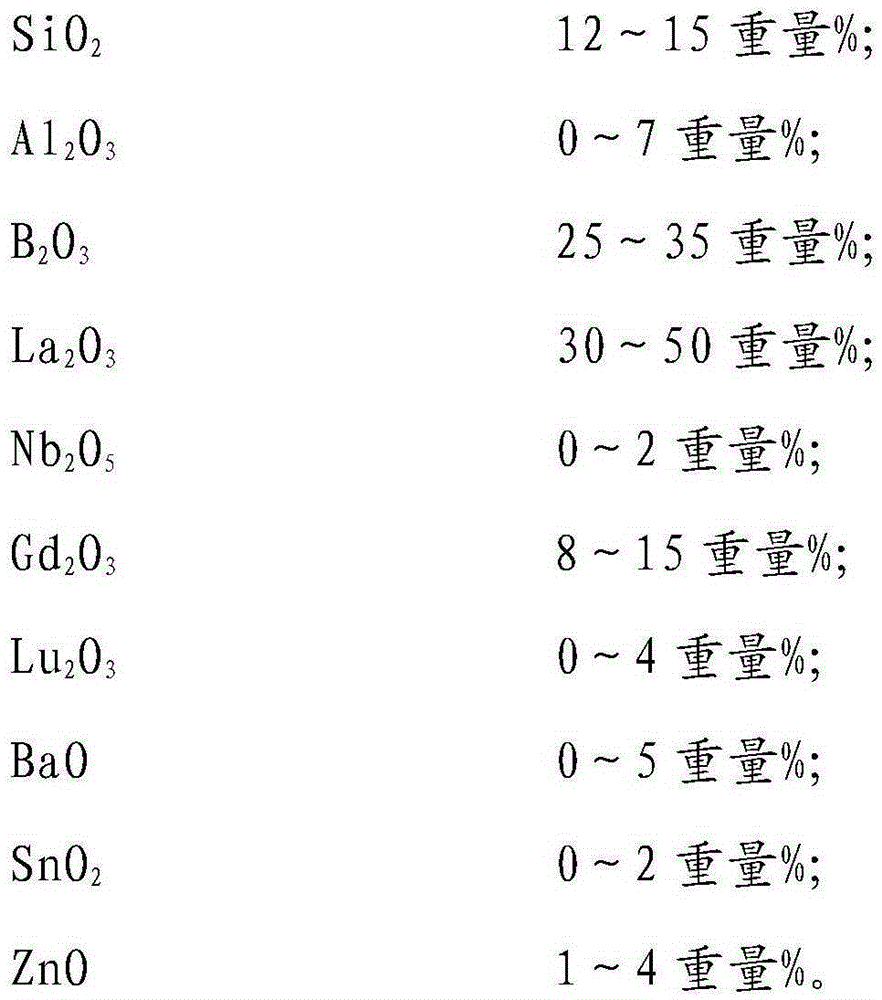

[0049] ①Preparation of glass batch materials: Weigh each raw material according to the raw material components, mix and grind all raw materials evenly to obtain batch materials;

[0050] ② Melting of glass batch materials: Mix the above prepared glass batch materials evenly, put them into platinum crucibles, and place them in a glass melting furnace under a reducing atmosphere for melting. The glass melted under reducing atmosphere conditions can effectively improve The flickering luminous efficiency of the glass and the reduction atmosphere are obtained by directly passing the mixed gas of nitrogen and hydrogen into the crucible with the batch material, the melting temperature is 1400-1500 ℃, and the temperature is kept for 6-9 hours after melting. Perform manual stirring 3 times to improve the melting quality and clarification quality of the ...

Embodiment 1

[0064] First, select the raw materials according to the glass composition of Example 1 in Table 1, so that the ingredients meet the chemical composition of the glass in Table 1. After thorough mixing and grinding, the glass batch is prepared, and then poured into a platinum crucible, at a temperature of 1450 ° C. Melt in a glass melting furnace in a reducing atmosphere, directly pass the mixed gas of hydrogen and nitrogen into the crucible with batching materials to obtain a reducing atmosphere, heat it for 8 hours after melting, and manually stir the glass liquid 3 times during the heat preservation period. Improve the melting quality and clarification quality of the glass melt. After the glass batch material is melted into a homogeneous glass melt, the glass melt leakage is formed into a glass rod and placed in a muffle furnace at 600°C for annealing treatment. Turn off the electric furnace after one hour, then cool down to room temperature naturally with the furnace cooling,...

Embodiment 2

[0066] Select raw materials according to the glass composition of Example 2 in Table 1, so that the ingredients meet the chemical composition of the glass in Table 1. After thorough mixing and grinding, the glass batch is prepared, then poured into a platinum crucible, and reduced with carbon monoxide at a temperature of 1400 ° C. It is melted in the glass melting furnace in the atmosphere, and the process of obtaining the carbon monoxide gas reducing atmosphere is to place a small crucible with carbon powder or graphite powder in the melting furnace for 2 hours to keep warm. After melting, keep it warm for 9 hours. During the heat preservation period, manually stir the molten glass 3 times to improve the melting quality and clarification quality of the glass melt. After the glass batch material is melted into a homogeneous glass melt, the glass melt leakage is formed into The glass rod is placed in a muffle furnace at 500°C for annealing treatment. After 4 hours of heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com