Sensing type geogrid material and structure thereof

A geogrid and sensor-type technology, applied in infrastructure engineering, sea area engineering, water conservancy engineering, etc., can solve the problems of increased monitoring difficulty and cost, undetectable, low tensile strength, etc., to avoid disturbance and sensor Insufficient durability itself, avoiding the effect of insufficient durability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

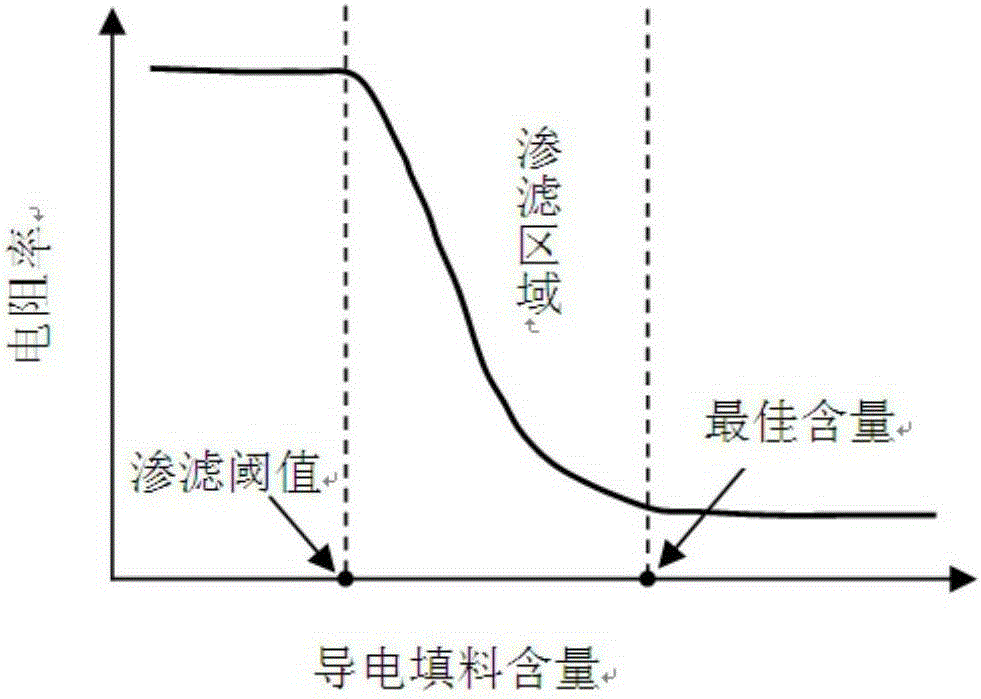

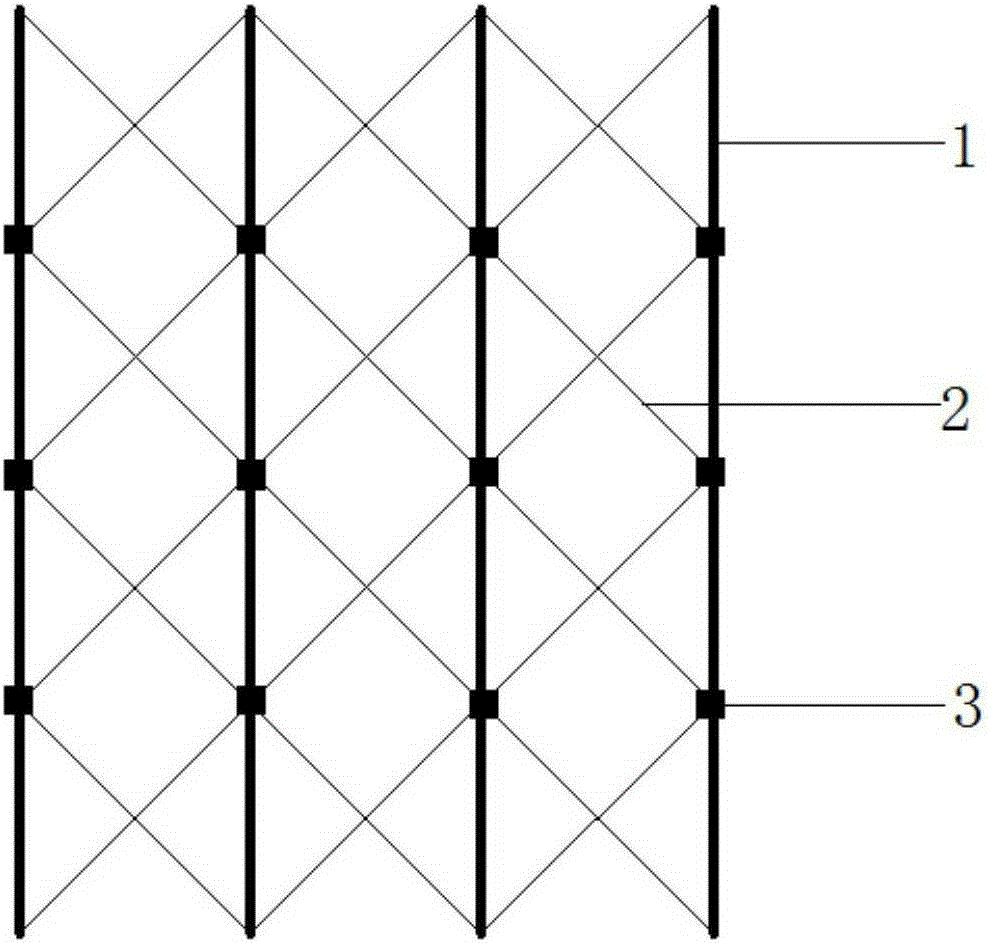

[0041] Example 1: Preparation of high-strength and high-conductivity geogrid

[0042] Geogrids can be used to reinforce the subgrade and pavement of highways, airports, parking lots, etc., where the traffic flow and load are large, so higher requirements are put forward for the strength and toughness of the grid. In order to prepare a high-strength and high-toughness grid, take 70g of carbon nanotubes, 140g of superconducting carbon black, 200g of nano-active calcium carbonate and 10g of titanate coupling agent, and the mass of high-density polyethylene is 580g. Carbon nanotubes, superconducting carbon black, and nano-active calcium carbonate were baked in an oven at 80-100°C for one hour to dehumidify; then titanate coupling agent and nano-active calcium carbonate were uniformly mixed; polyethylene, carbon nanotubes , superconducting carbon black, and the mixed coupling agent are uniformly mixed with nano-active calcium carbonate again, melted and granulated through a twin-sc...

example 2

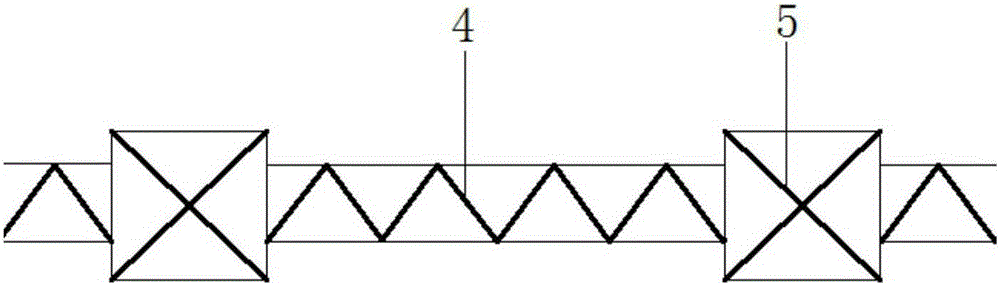

[0043] Example 2: Application of high-strength, high-friction sensing grid in engineering

[0044] Geogrids can strengthen soil and prevent uneven settlement in road and construction projects. To prepare sensory geogrids, the contents of carbon nanotubes and carbon black are selected to be 6% and 12%, respectively, and nano-active carbonic acid The calcium content is 20%, the coupling agent is 5% of the nano-active calcium carbonate content, and the high-density polyethylene matrix content is 61%. The manufacturing steps of the grid are the same as in Example 1. According to the laboratory test, its tensile strength reaches 22.51MPa, and its normalized resistivity and strain relationship is: where: Ω 0 and Ω represent the initial resistance of the grid and the resistance during tensile deformation, respectively, and ε is the strain of the grid. The fitting curve of the relationship between normalized resistivity and strain is as follows: Figure 4 shown. In actual enginee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com