Solvent-free modified polyurethane paint and preparation method thereof

A solvent-free polyurethane and polyurethane coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, conductive coatings, etc., can solve the problems of high VOC substances, low solid content, poor thermal insulation and static conductivity, etc., and achieve good performance, Simple operation and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

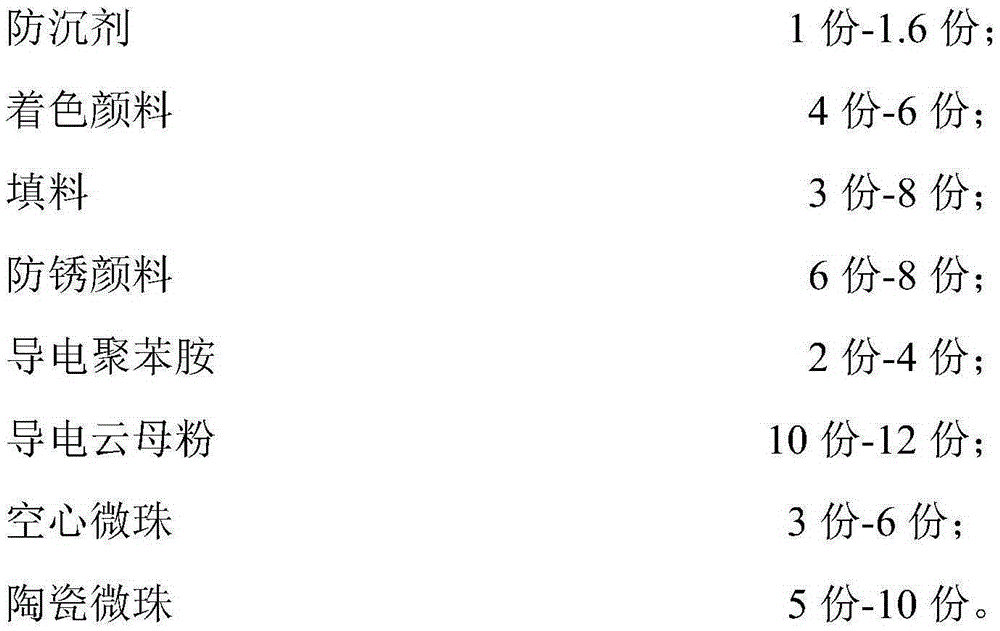

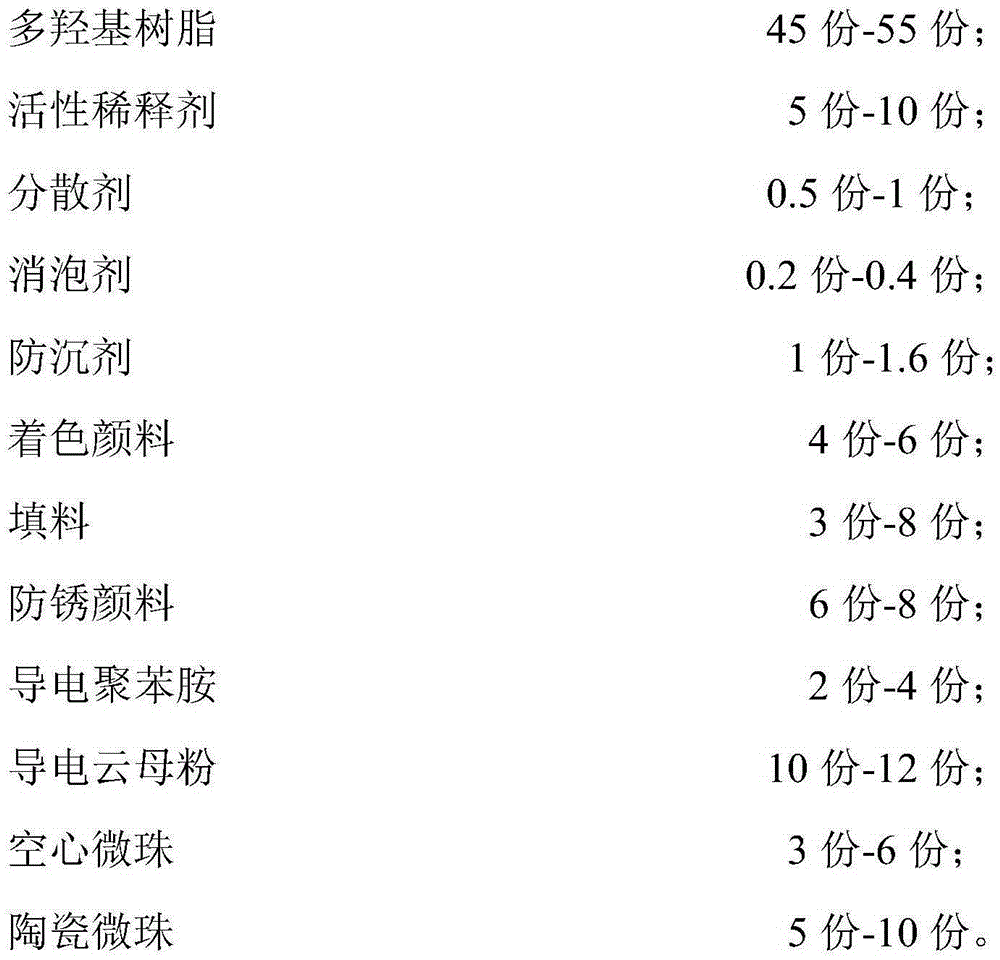

[0031] On the other hand, the present invention also provides a preparation method of the modified solvent-free polyurethane coating in the above embodiment of the present invention. The preparation method of the modified solvent-free polyurethane coating includes the following steps:

[0032] Step S01: Mixing the polyhydroxy resin, active diluent, dispersant, defoamer and anti-settling agent to prepare the first mixture;

[0033] Step S02: adding fillers, coloring pigments, anti-rust pigments and conductive polyaniline to the first mixture for homogenization processing to prepare a second mixture;

[0034] Step S03: Add conductive mica powder to the second mixture and mix to prepare a third mixture;

[0035] Step S04: adding hollow microbeads and ceramic microbeads to the third mixture for homogenization, and preparing a modified solvent-free polyurethane coating.

[0036] Among them, in the above step S01, the mixing equipment is not limited, it can be a dispersion cylinder, and the ...

Embodiment 1

[0041] The modified solvent-free polyurethane coating according to the above-mentioned material weight component distribution ratio and the above-mentioned preparation method is as follows: 45 parts of polyhydroxy resin, 5 parts of reactive diluent, 0.5 part of dispersant, 0.2 part of defoamer, 1.3 parts of anti-settling agent, 8 parts of fillers, 4 parts of coloring pigments, 6 parts of anti-rust pigments, 2 parts of conductive polyaniline, 12 parts of conductive mica, 6 parts of hollow microbeads, and 10 parts of ceramic microbeads.

[0042] Among them, the anti-settling agent is polyamide wax powder, the filler is a combination of talc powder and mica powder, 4 parts each, and the anti-rust pigment is zinc phosphate.

[0043] In step S01, the mixing equipment is a dispersing cylinder, and the dispersing time is 10 minutes at room temperature;

[0044] In step S02, the mixing equipment is a dispersion cylinder, the mixing temperature is 65°C, and the dispersion time is 15 minutes; ...

Embodiment 2

[0049] The modified solvent-free polyurethane coating according to the above-mentioned material weight component distribution ratio and the above-mentioned preparation method is as follows: 48 parts of polyhydroxy resin, 7 parts of reactive diluent, 0.6 part of dispersant, 0.3 part of defoamer, 1.1 parts of anti-settling agent, 3 parts of fillers, 5 parts of coloring pigments, 8 parts of anti-rust pigments, 3 parts of conductive polyaniline, 10 parts of conductive mica, 5 parts of hollow beads and 9 parts of ceramic beads.

[0050] Among them, the anti-settling agent is polyamide wax powder, the filler is talc powder, and the anti-rust pigment is aluminum tripolyphosphate.

[0051] In step S01, the mixing equipment is a dispersing tank, and the dispersing time is 13 minutes at room temperature;

[0052] In step S02, the mixing equipment is a dispersion cylinder, the mixing temperature is 65°C, and the dispersion time is 18 minutes;

[0053] In step S03, the mixing equipment is a dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com