Method for pretreating lignocellulose by utilizing cold plasmas

A lignocellulose and cold plasma technology, which is applied in fermentation and other directions, can solve the problems of slow processing speed, high cost of pretreatment process, low temperature required, etc., and achieves a pollution-free environment, high efficiency and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

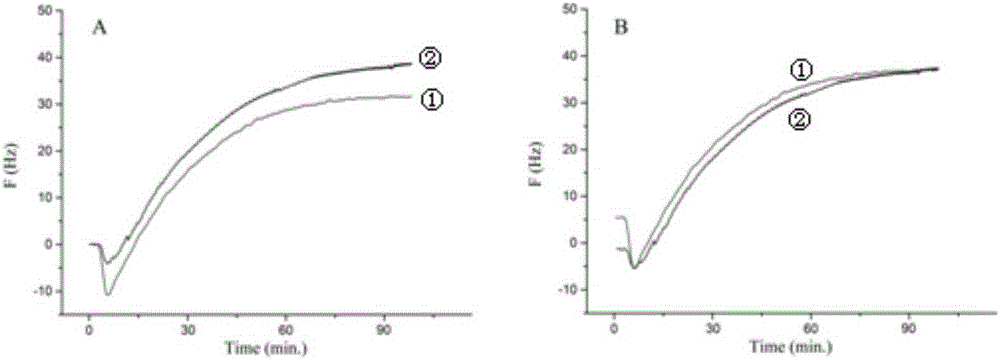

[0018] Remove the sundries in the rice straw, then wash the straw, dry it at 50°C to remove water, and then use a ball mill to crush it to more than 150 mesh to obtain the crushed lignocellulose raw material, and then add the lignocellulose raw material to the medium In the barrier discharge plasma device, start the machine and warm up for 6 minutes, with O 2 The atmosphere is used as the modification treatment atmosphere, O 2 The flow rate is 0.05L / min, the regulating voltage is 30v to obtain a processing power of 300W, and the modification pretreatment time is 20s.

[0019] Use cellulase to hydrolyze the modified product, the amount of enzyme added is 35U / g (to the dry weight of cellulose), the enzymolysis temperature is 40°C, pH4.6, the enzymolysis time is 96 hours, and the glucose conversion determined by high performance anion exchange chromatography Its cellulase hydrolysis yield is 45.4%.

Embodiment 2

[0024] Remove the sundries in the corn stalks, then wash the stalks, dry them at 50°C to remove moisture, and use a ball mill to crush them to more than 150 mesh to obtain crushed lignocellulose raw materials, and then add lignocellulose raw materials to the medium In the barrier discharge plasma device, start up and warm up for 7 minutes, and use N 2 The atmosphere is used as the modification treatment atmosphere, N 2 The flow rate is 0.06L / min, the regulating voltage is 20v to obtain a processing power of 300W, and the modification pretreatment time is 30s.

[0025] Use cellulase to hydrolyze the modified product, the amount of enzyme added is 35U / g (to the dry weight of cellulose), the enzymolysis temperature is 40°C, pH4.6, the enzymolysis time is 96 hours, and the glucose conversion determined by high performance anion exchange chromatography Its cellulase hydrolysis yield is 48.5%.

Embodiment 3

[0027] Remove the sundries in the rice straw, then wash the straw, dry it at 50°C to remove water, and then use a ball mill to crush it to more than 150 mesh to obtain the crushed lignocellulose raw material, and then add the lignocellulose raw material to the medium In the barrier discharge plasma device, start the machine and warm up for 6 minutes, with O 2 The atmosphere is used as the modification treatment atmosphere, O 2 The flow rate is 0.05L / min, the regulating voltage is 50v to obtain a processing power of 300W, and the modification pretreatment time is 40s.

[0028] Use cellulase to hydrolyze the modified product, the amount of enzyme added is 35U / g (to the dry weight of cellulose), the enzymolysis temperature is 40°C, pH4.6, the enzymolysis time is 96 hours, and the glucose conversion determined by high performance anion exchange chromatography Its cellulase hydrolysis yield is 57.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com