Al2O3-SiO2 high-temperature insulating coating on surface of metal tungsten and preparation method thereof

An al2o3-sio2, high temperature insulation technology, applied in metal material coating process, coating, solid diffusion coating and other directions, to achieve the effect of excellent performance, good electrical insulation performance and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

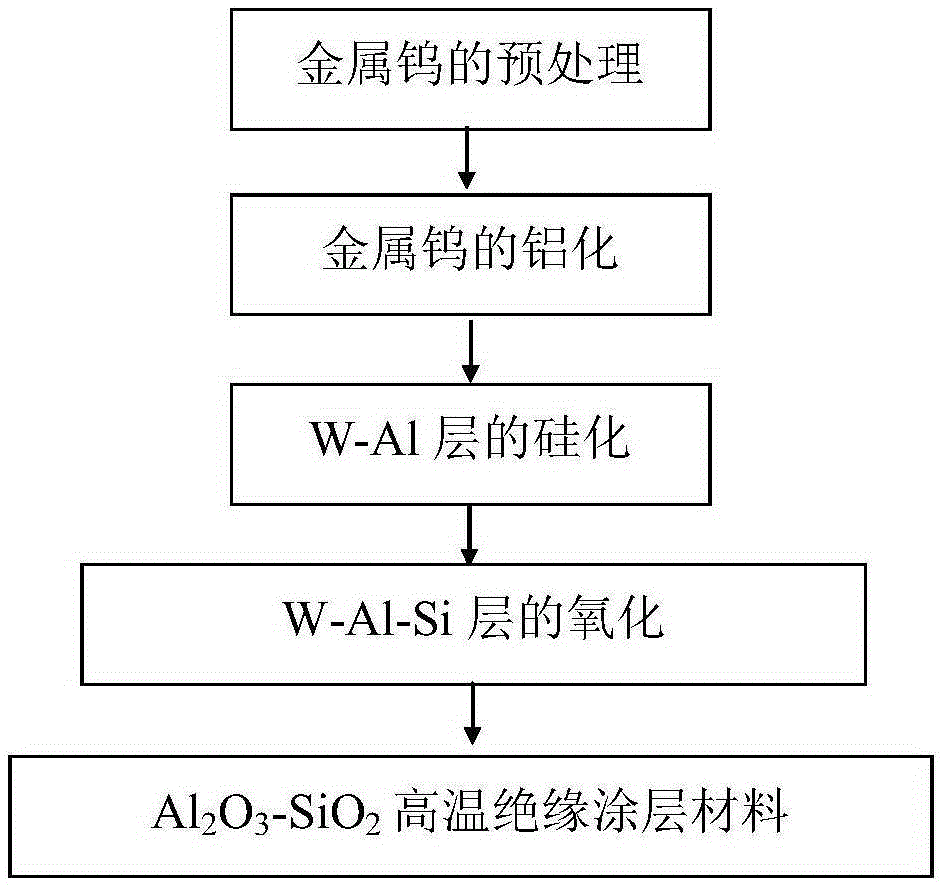

[0022] Preparation process see figure 1 .

[0023] (1) Pretreatment of tungsten base material: Polish the metal tungsten base material with sandpaper until the surface is smooth and flat, and put it into absolute ethanol or ethanol solution for oil degreasing treatment, then dry and set aside.

[0024] (2) Aluminization treatment: put the pretreated metal tungsten into an alumina crucible with a uniformly mixed aluminizing agent, which contains elemental aluminum powder, NaF, Al 2 o3 The mass ratio of the three is 15:5:80, and then placed in the furnace to heat, and pass inert gas or hydrogen as a protective atmosphere, raise the temperature to 1000°C at a rate of 10°C / min and keep it at 1000°C for 20 hours. After the furnace cools down, take it out, boil it in distilled water for 5-10 minutes, rinse it with deionized water, wipe and dry it with ethanol, and obtain a semi-finished product A with a W-Al coating on the metal tungsten surface.

[0025] (3) Siliconization treatm...

Embodiment 2

[0028] Preparation process see figure 1 .

[0029] (1) Pretreatment of tungsten base material: Polish the metal tungsten base material with sandpaper until the surface is smooth and flat, and put it in absolute ethanol or ethanol solution for oil degreasing treatment, then dry it and set it aside.

[0030] (2) Aluminization treatment: put the pretreated metal tungsten into an alumina crucible with a uniformly mixed aluminizing agent, which contains elemental aluminum powder, NaF, Al 2 o 3 The mass ratio of the three is 20:10:70, and then placed in the furnace to heat, and pass inert gas or hydrogen as a protective atmosphere, the temperature rises to 1100°C at a rate of 30°C / min and is kept at 1100°C for 15 hours. After the furnace cools down, take it out, boil it in distilled water for 5-10 minutes, rinse it with deionized water, wipe and dry it with ethanol, and obtain a semi-finished product A with a W-Al coating on the metal tungsten surface.

[0031] (3) Siliconization...

Embodiment 3

[0034] Preparation process see figure 1 .

[0035] (1) Pretreatment of tungsten base material: Polish the metal tungsten base material with sandpaper until the surface is smooth and flat, and put it into absolute ethanol or ethanol solution for oil degreasing treatment, then dry and set aside.

[0036] (2) Aluminization treatment: put the pretreated metal tungsten into an alumina crucible with a uniformly mixed aluminizing agent, which contains elemental aluminum powder, NaF, Al 2 o 3 The mass ratio of the three is 25:15:60, then put it in the furnace to heat, and pass inert gas or hydrogen as a protective atmosphere, raise the temperature to 1200°C at a rate of 20°C / min and keep it at 1200°C for 10 hours. Take it out after cooling down in the furnace, boil it in distilled water for 5-10 minutes, rinse it with deionized water, wipe it with ethanol and dry it to obtain a semi-finished product A with a W-Al coating on the metal tungsten surface.

[0037] (3) Siliconization tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com