Corrosion-resisting magnetically soft alloy

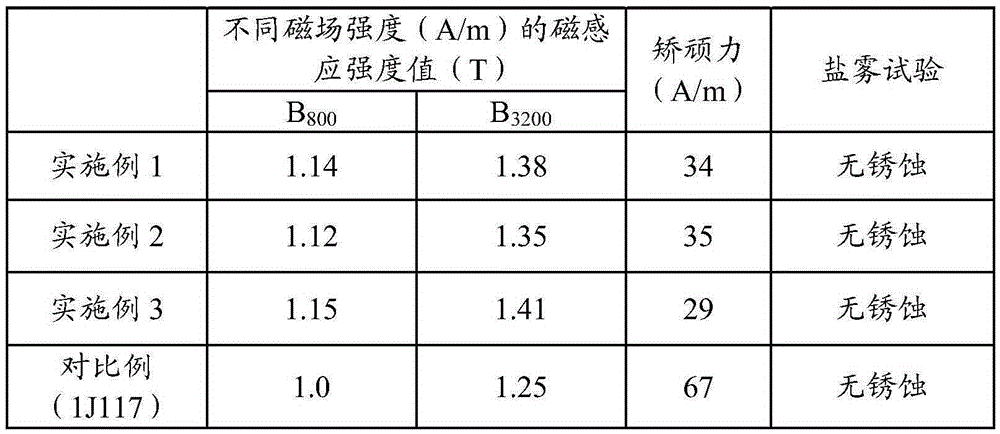

A soft magnetic alloy and corrosion-resistant technology, applied in the field of corrosion-resistant soft magnetic alloys and electromagnetic fuel injectors, can solve the problems of high coercivity, high price, can not meet the requirements of material selection, etc., and achieve low price and reduce coercivity. , the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

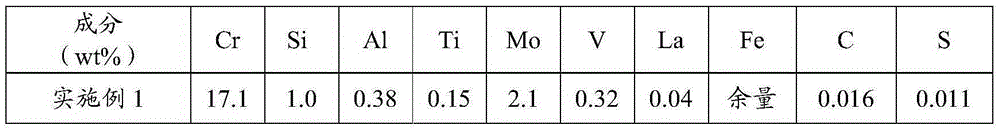

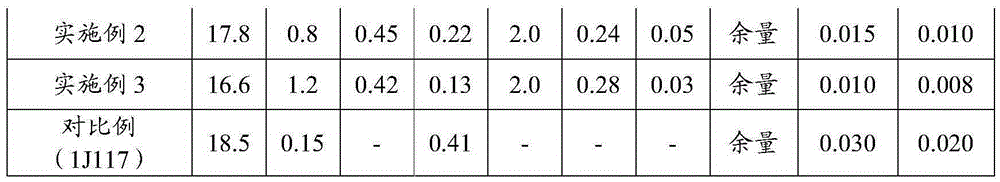

Examples

preparation example Construction

[0017] The preparation method of the alloy of the invention is as follows: industrial pure iron, metal chromium, electrolytic nickel, sponge titanium, polysilicon, metal molybdenum, metal aluminum, vanadium iron alloy, rare earth lanthanum and the like are used as raw materials. Vacuum induction melting or AOD (Argon Oxygen Decarburization), VOD (Vacuum Oxygen Decarburization) and other out-of-furnace refining technologies are easy to industrial scale production. For those with special requirements, electroslag remelting (ESR) and vacuum arc remelting (VAR) can also be carried out.

[0018] Among them, the alloy is smelted and poured in a vacuum induction furnace, and then forged into a Ф40mm forged rod after being kept at 1160°C. After the forged rod is heat treated, the relevant properties are tested. The heat treatment process adopted is: heat preservation at 980°C for 8 hours, cooling to 700°C at a cooling rate of 50°C / h, and then cooling to room temperature with the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com