High conductivity, corrosion resistance and long life max phase solid solution composite coating, its preparation method and application

A composite coating and long-life technology, which is applied in coatings, metal material coating processes, circuits, etc., can solve problems that affect battery life and performance, increase interface contact resistance, and insufficient target ionization rate, etc., to improve Corrosion resistance, high plasma density, and the effect of avoiding columnar defect penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the embodiments of the present invention provides a method for preparing a high-conductivity, corrosion-resistant, and long-life MAX phase solid-solution composite coating, comprising:

[0026] Provide metal bipolar plate substrate;

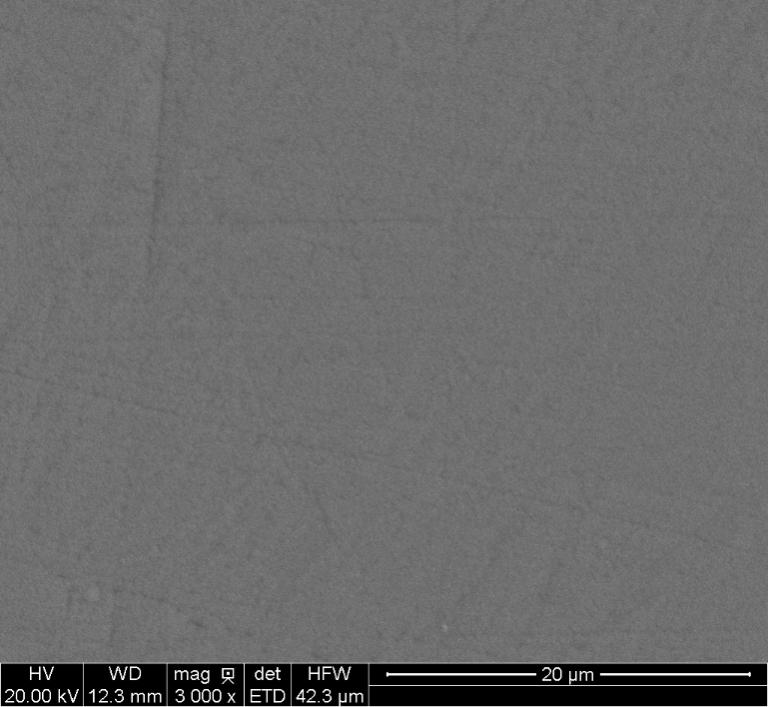

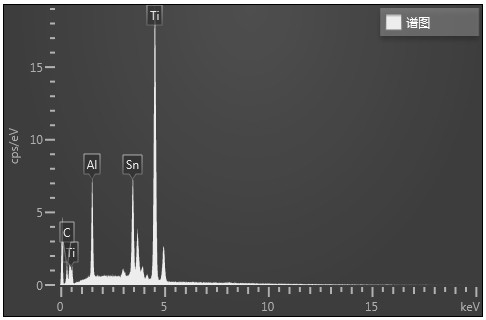

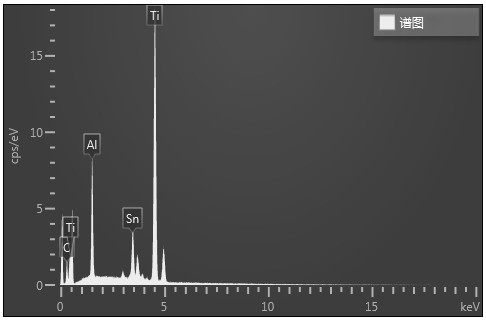

[0027] Using high-power pulsed magnetron sputtering technology, alternately deposit Ti-Al-C layers and Ti-Sn-C layers on the surface of the metal bipolar plate substrate, thereby forming an alternate stack of Ti-Al-C / Ti-Sn-C layer, wherein the Ti-Al-C / Ti-Sn-C alternate stacking layer includes 2 to 10 alternate stacking periodic layers, and each alternate stacking periodic layer includes a Ti-Al-C layer and a Ti-Sn-C layer ;

[0028] And, vacuum heat treatment is carried out on the Ti-Al-C / Ti-Sn-C alternate lamination to form Ti 2 (Al 1-x sn x ) CMAX phase solid solution composite coating, that is, high conductivity, corrosion resistance and long life MAX phase solid solution composite coating, where 0 <x <1.

[0029] In ...

Embodiment 1

[0053] In this embodiment, the substrate is a 316L stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the Ti on the surface of the substrate is 2 (Al 0.5 sn 0.5 ) The preparation method of C MAX phase solid solution composite coating is as follows:

[0054] (1) The surface of the polished metal substrate is first ultrasonically cleaned with acetone and ethanol for 10 minutes and dried, then put into the cavity, and the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 50 sccm of argon gas is introduced into the vacuum chamber, the voltage of the linear anode ion source is set to 1200V, the bias voltage of the substrate is -200V, and the substrate is etched with ionized argon ions for 30 minutes;

[0055] (2) The Ti-Al-C layer was deposited by high-power pulsed magnetron sputtering technology, in which Ti 0.5 Al 0.5 Alloy target provides Ti source and Al source, gas CH 4 Provide C source, CH 4 Flow rate is 2sccm, argon flow rate is 100scc...

Embodiment 2

[0061] In this embodiment, the substrate is a 316L stainless steel bipolar plate used in a proton exchange membrane fuel cell, and the Ti on the surface of the substrate is 2 (Al 0.6 sn 0.4 ) The preparation method of C MAX phase solid solution composite coating is as follows:

[0062] (1) The surface of the polished metal substrate is first ultrasonically cleaned with acetone and ethanol for 10 minutes and dried, then put into the cavity, and the vacuum pressure in the cavity is 3.0×10 -5 Below Torr, 50 sccm of argon gas is introduced into the vacuum chamber, the voltage of the linear anode ion source is set to 1200V, the bias voltage of the substrate is -200V, and the substrate is etched with ionized argon ions for 30 minutes;

[0063] (2) The Ti-Al-C layer was deposited by high-power pulsed magnetron sputtering technology, in which Ti 0.3 Al 0.7 Alloy target provides Ti source and Al source, gas CH 4 Provide C source, CH 4 Flow rate is 2sccm, argon flow rate is 100scc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com