Method for preparing manganese dioxide/carbon microsphere electrode by organic matter electrolytic process

A manganese dioxide and carbon microsphere technology, applied in the field of material chemistry, can solve the problems of high energy consumption, complex manganese dioxide/carbon microsphere electrode process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

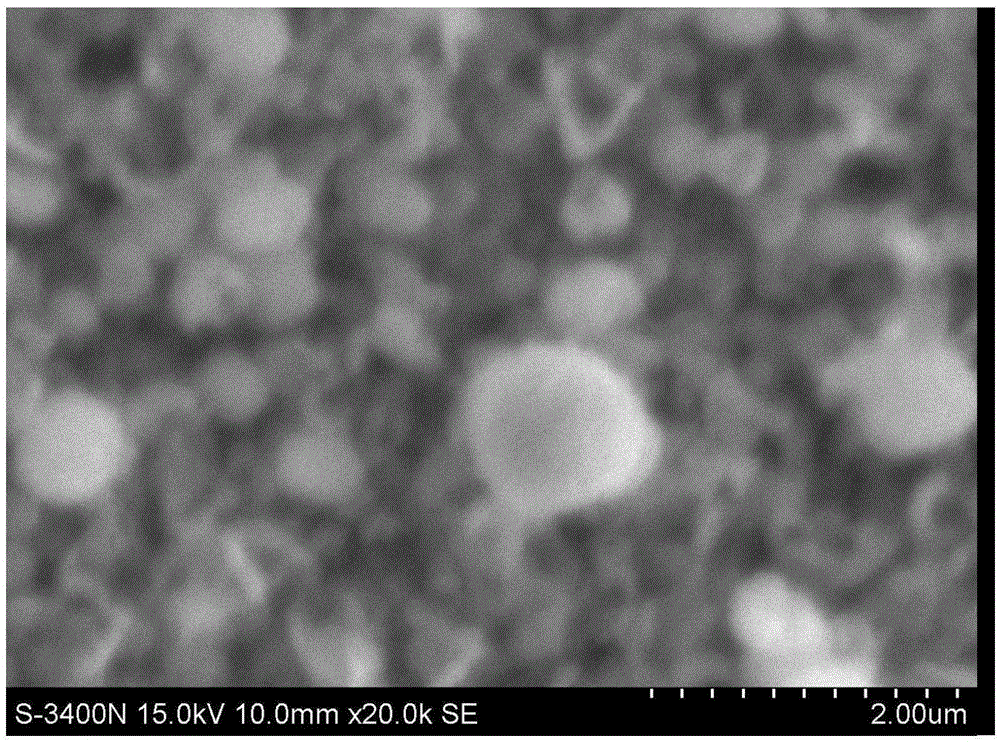

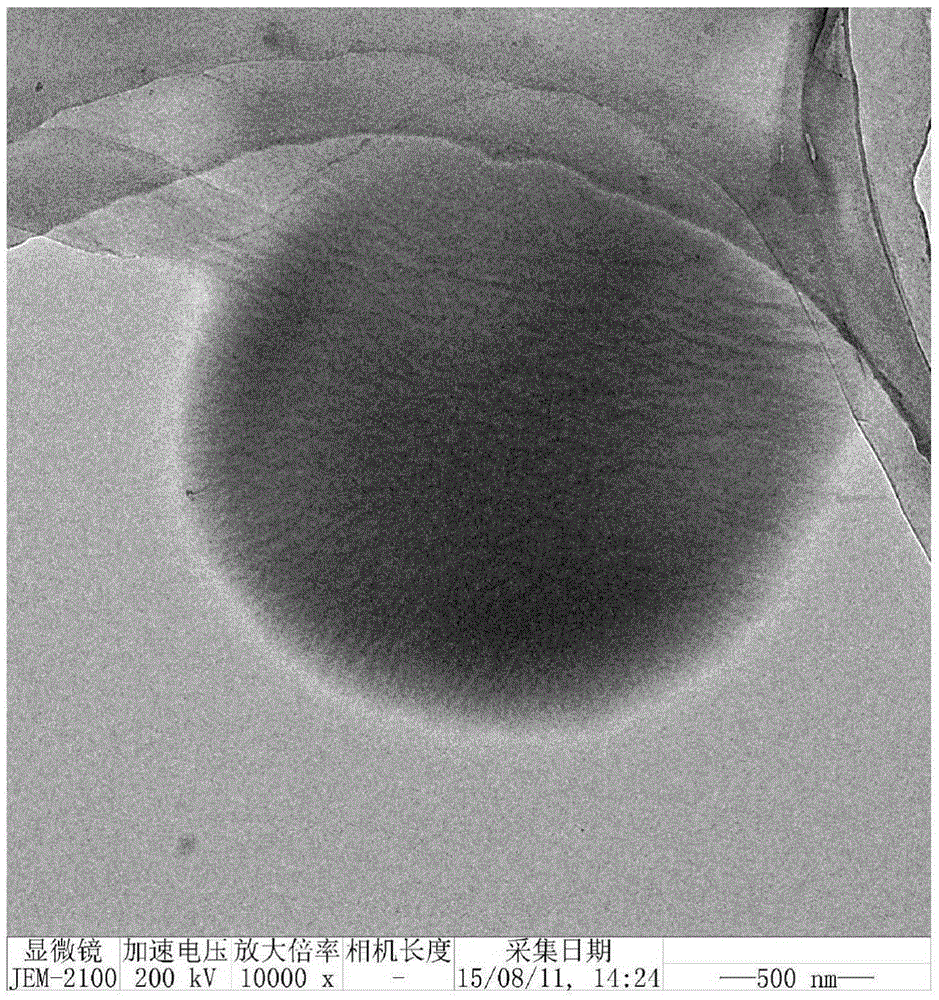

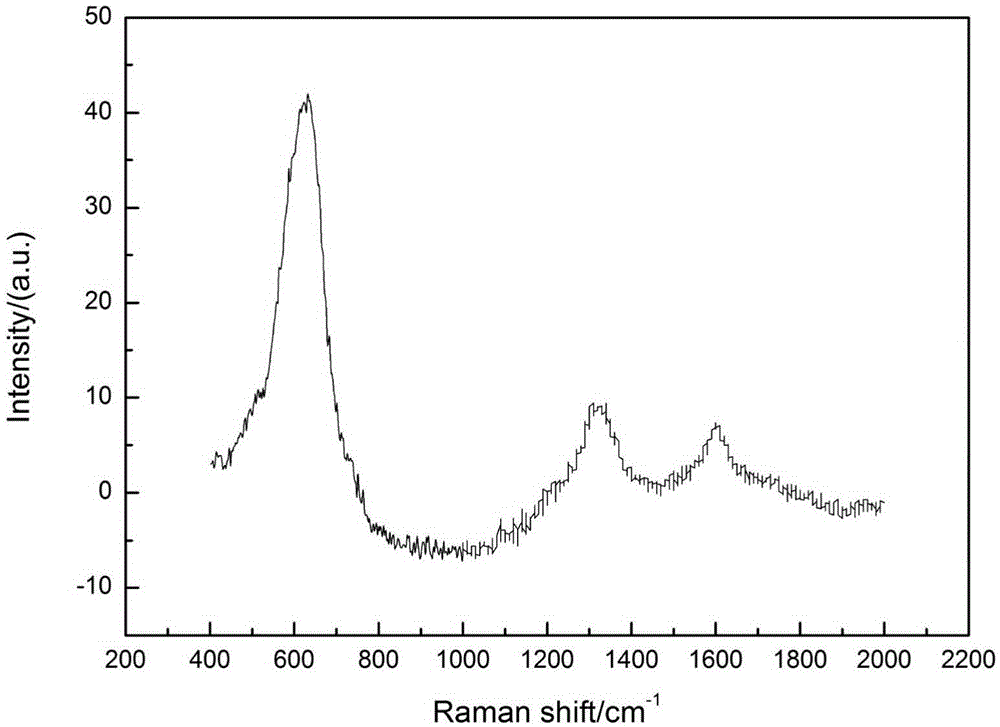

[0017] A kind of method utilizing organic matter electrolysis of the present invention to prepare manganese dioxide / carbon microspheres specifically comprises the following steps:

[0018] (1) With stainless steel electrode as cathode, platinum sheet electrode as anode, manganese nitrate with a concentration of 0.001mol / L and NMP aqueous solution with a volume concentration of 0.1 as electrolyte, under the condition of 50℃, constant voltage 100v, electrolysis 30min. After electrolysis, the product obtained on the cathode is rinsed with deionized water, and then dried at 80° C. to obtain a manganese dioxide / carbon microsphere electrode.

Embodiment 2

[0020] A kind of method utilizing organic matter electrolysis of the present invention to prepare manganese dioxide / carbon microspheres specifically comprises the following steps:

[0021] (1) Using the Ti sheet electrode as the cathode, the platinum sheet electrode as the anode, and the NMP aqueous solution containing manganese nitrate with a concentration of 0.001mol / L and a volume concentration of 0.1 as the electrolyte, under the condition of 50°C, a constant voltage of 200v, Electrolysis for 30min. After electrolysis, the product obtained on the cathode is rinsed with deionized water, and then dried at 80° C. to obtain a manganese dioxide / carbon microsphere electrode.

Embodiment 3

[0023] A kind of method utilizing organic matter electrolysis of the present invention to prepare manganese dioxide / carbon microspheres specifically comprises the following steps:

[0024] (1) The stainless steel sheet electrode is used as the cathode, the platinum sheet electrode is used as the anode, the manganese nitrate solution with a concentration of 0.005mol / L and the NMP aqueous solution with a volume concentration of 0.1 are used as the electrolyte, and the constant voltage is 5v at 50°C. Electrolysis 8h. After electrolysis, the product obtained on the cathode is rinsed with deionized water, and then dried at 80° C. to obtain a manganese dioxide / carbon microsphere electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com