A kind of preparation method of wear-resistant soft polyester bulky filament

A technology of bulked filament and polyester, which is applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of non-implementation, etc., and achieve improved mechanical properties, improved wear resistance, The effect of maintaining aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

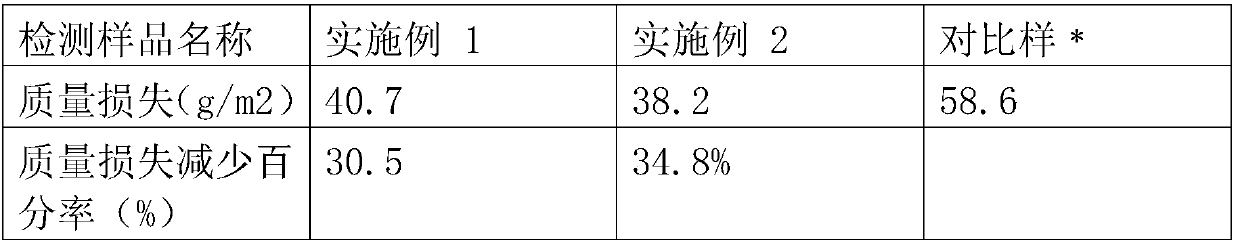

Examples

Embodiment 1

[0036] Preparation of wear-resistant and soft PBT / PET bulked filament

[0037] a. Preparation of talcum powder masterbatch (weight ratio): 50% talc powder, 44% polybutylene terephthalate, 3% POE with maleic anhydride, 1% zinc stearate, 1010 0.1 antioxidant %, antioxidant 168 0.1%, triphenyl phosphite 2%, all added to a high-speed mixer, high-speed mixing for 10 minutes, twin-screw extruder melt blending extrusion, granulation;

[0038] Raw material requirements:

[0039] Talc powder: average particle size 1.4μm, whiteness ≥ 90%, silane coupling agent KH560 surface modification, water content ≤ 50ppm,

[0040] Polybutylene terephthalate: intrinsic viscosity 1.03~1.09dl / g, moisture ≤50ppm,

[0041] Maleic anhydride grafting POE: grafting rate 0.8-1.2%, melt index (190°C, 2.16kg): 1.0-2.5g / 10min.

[0042] b. Spinning (weight ratio): 61% of dry PBT chips, 23% of PET chips, 16% of dry superfine talcum powder masterbatch, and add the feed screw of BCF spinning unit simultaneously...

Embodiment 2

[0053] Preparation of wear-resistant and soft PTT / PBT bulked filament

[0054] a. Preparation of talcum powder masterbatch (weight ratio): talcum powder 40%, polybutylene terephthalate 52%, maleic anhydride grafted PP 5%, zinc stearate 1%, antioxidant 1010 0.1 %, antioxidant 168 0.1%, triphenyl phosphite 2%, all added to a high-speed mixer, high-speed mixing for 10 minutes, twin-screw extruder melt blending extrusion, granulation;

[0055] Raw material requirements:

[0056] Talc powder: average particle size 0.8μm, whiteness ≥ 90%, silane coupling agent KH560 surface modification, moisture content ≤ 50ppm,

[0057] Polybutylene terephthalate: intrinsic viscosity 1.03~1.09dl / g, moisture ≤50ppm,

[0058] Maleic anhydride grafted PP: graft rate: 0.8-1.2%, melt index 49-51g / 10min.

[0059] b. Spinning (weight ratio): 70% of dry PTT chips, 15% of PBT chips, 15% of dry superfine talcum powder masterbatch, and add the feeding screw of BCF spinning unit simultaneously, through scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com