Conductive slurry

A technology of conductive paste and conductive metal, applied in the direction of multilayer capacitors, fixed capacitor electrodes, fixed capacitor parts, etc., can solve the problems of deterioration of cutability, insufficient removal of acidic dispersants, and increased peeling force. , to achieve the effect of inhibiting sheet erosion, inhibiting poor peeling of green sheets, and small viscosity change with time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

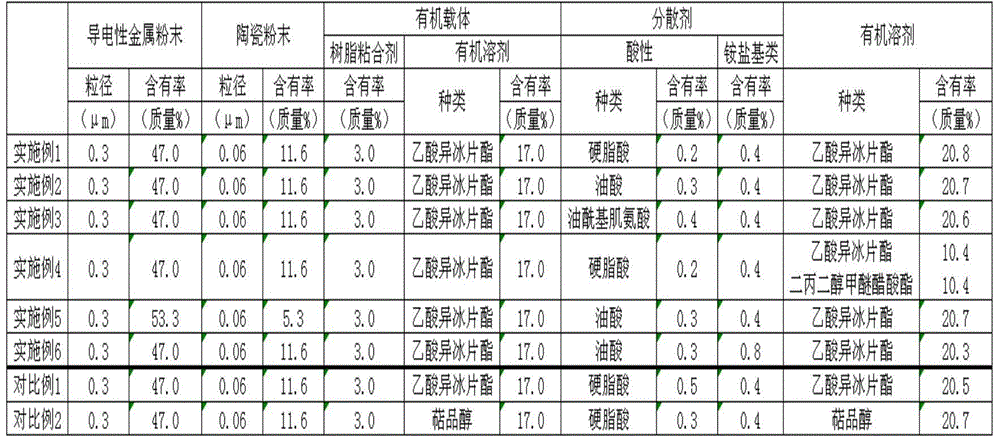

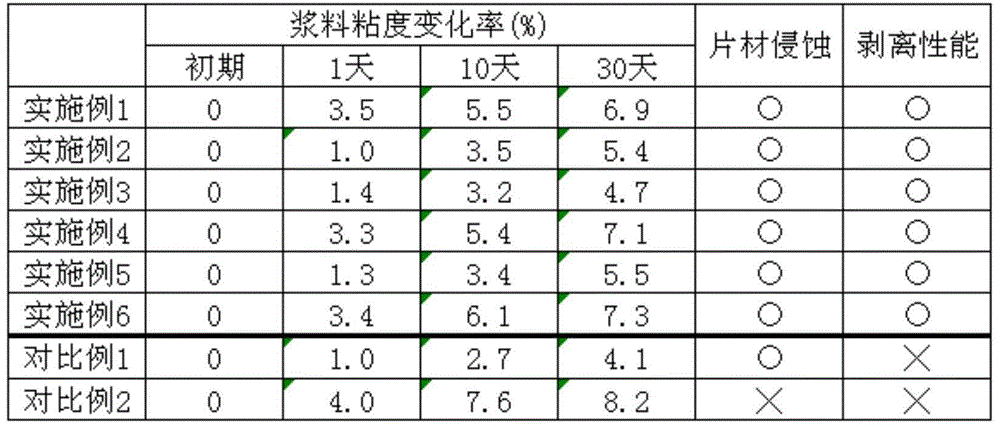

[0101] As shown in Table 2, 47.0% by mass of nickel powder (Ni) having a particle size of 0.3 μm as a conductive metal powder, 11.6% by mass of barium titanate (BT) having a particle size of 0.06 μm as a ceramic powder, 20.0% by mass of the above-mentioned organic vehicle 1 and dispersant 1 composed of 0.2% by mass of acidic dispersant and 0.4% by mass of salt-based dispersant were dissolved in 20.8% by mass of organic solvent 1 to prepare a conductive paste.

Embodiment 2

[0103] As shown in Table 2, 47.0% by mass of nickel powder (Ni) having a particle size of 0.3 μm as a conductive metal powder, 11.6% by mass of barium titanate (BT) having a particle size of 0.06 μm as a ceramic powder, 20.0% by mass of the above-mentioned organic vehicle 1 and dispersant 2 composed of 0.3% by mass of acidic dispersant and 0.4% by mass of salt-based dispersant were dissolved in 20.7% by mass of organic solvent 1 to prepare a conductive paste.

Embodiment 3

[0105] As shown in Table 2, 47.0% by mass of nickel powder (Ni) having a particle size of 0.3 μm as a conductive metal powder, 11.6% by mass of barium titanate (BT) having a particle size of 0.06 μm as a ceramic powder, 20.0% by mass of the above-mentioned organic vehicle 1 and dispersant 3 composed of 0.4% by mass of acidic dispersant and 0.4% by mass of salt-based dispersant were dissolved in 20.6% by mass of organic solvent 1 to prepare a conductive paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com