A kind of preparation method of acidic hydroxyapatite catalyzed solidification bone cement

A technology of acidic hydroxyapatite and hydroxyapatite, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of increasing biocompatibility, prolong the curing time, be suitable for mass production, and improve reliability injectable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

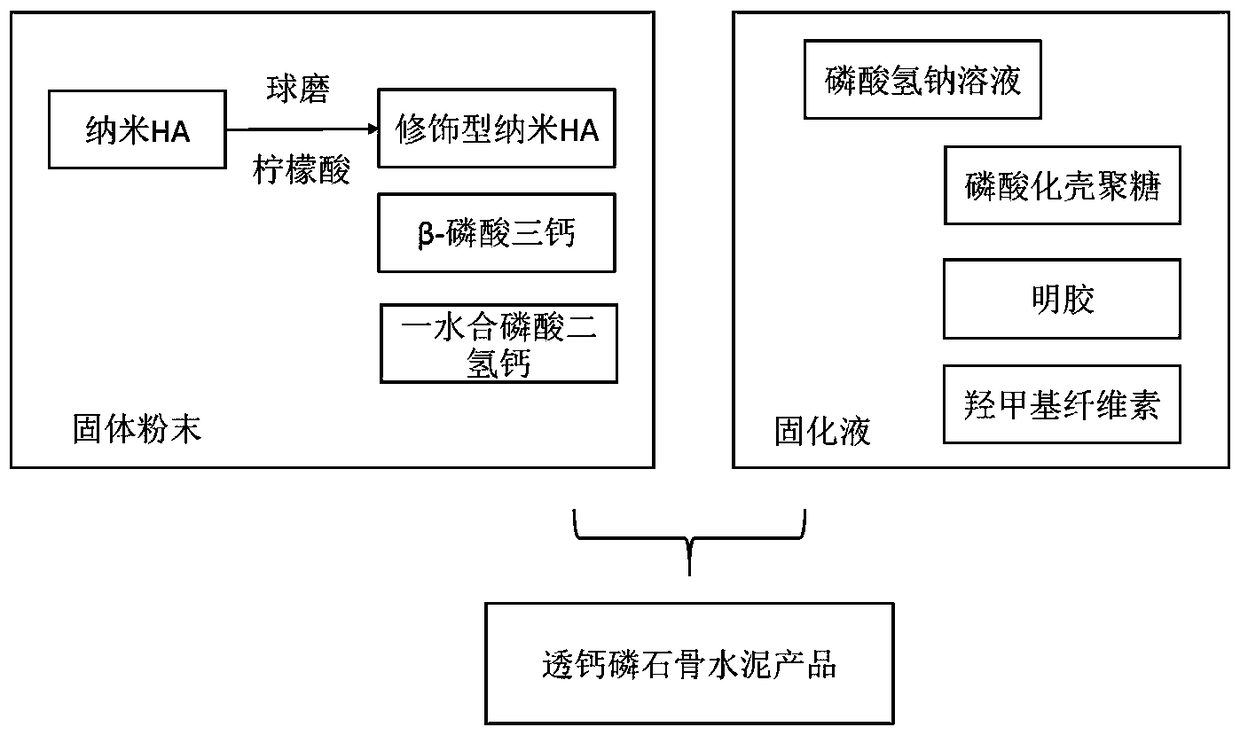

Method used

Image

Examples

Embodiment 1

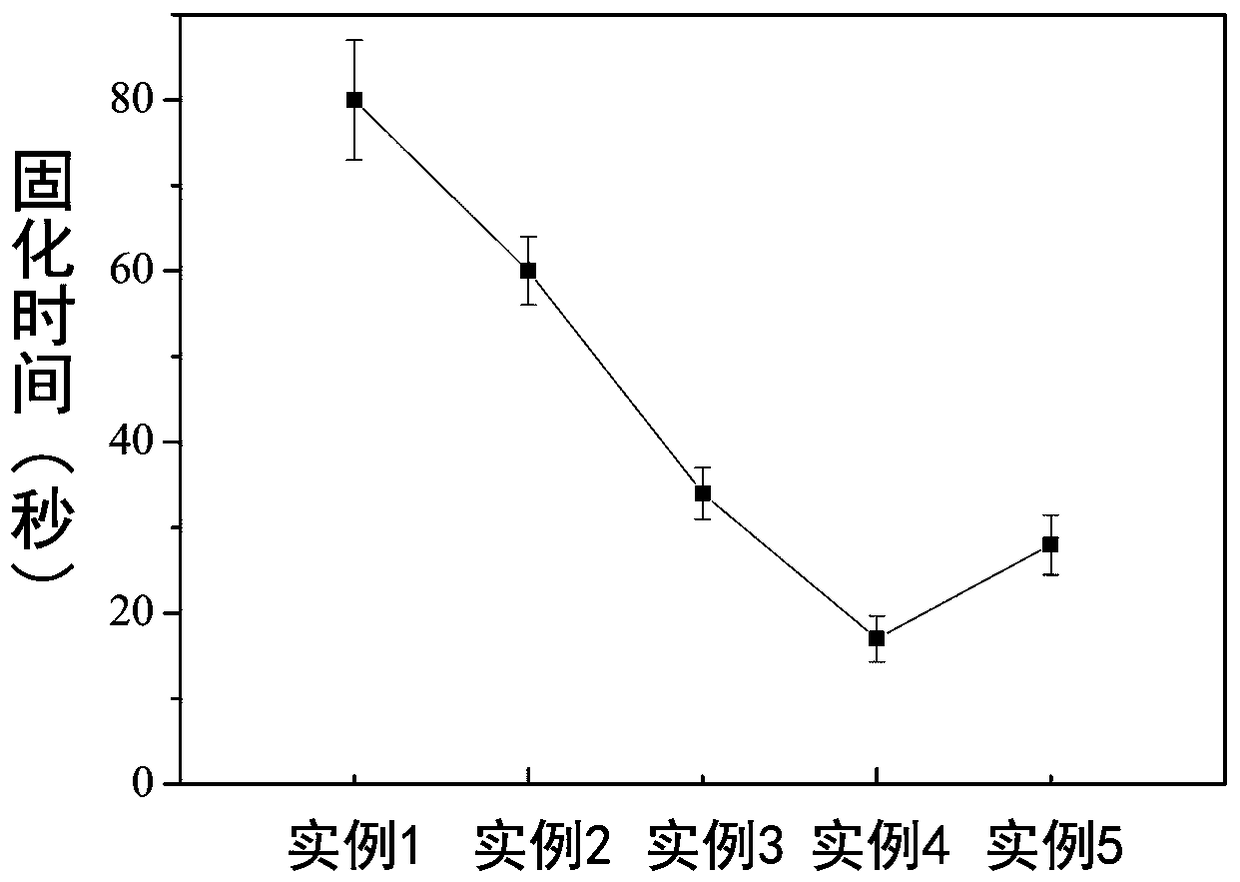

[0033] Weigh 0.2g phosphorylated chitosan, 0.2g gelatin, 0.2g hydroxypropyl methylcellulose, dissolve in 19.4g 20wt% sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan Sugar, 1% gelatin, 1% hydroxypropyl methylcellulose bone cement solidification solution. β-tricalcium phosphate, calcium dihydrogen phosphate monohydrate and modified hydroxyapatite were mixed at a ratio of 7:3, and the bone cement powder and curing liquid were mixed at a solid-liquid ratio of 1.5g / mL, referring to the standard ASTM The initial setting time of C191 was determined to be 80 min.

Embodiment 2

[0035]Weigh 0.2g phosphorylated chitosan, 0.2g gelatin, 0.2g hydroxypropyl methylcellulose, dissolve in 19.4g 20wt% sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan Sugar, 1% gelatin, 1% hydroxypropyl methylcellulose bone cement solidification solution. β-tricalcium phosphate, calcium dihydrogen phosphate monohydrate and modified hydroxyapatite were mixed in a ratio of 7:3:0.5, and the bone cement powder and curing liquid were mixed at a solid-liquid ratio of 1.5g / mL. The initial setting time measured by the standard ASTM C191 is 60 minutes, and the injectability is good, and solid-liquid separation does not occur under a certain pressure.

Embodiment 3

[0037] Weigh 0.2g phosphorylated chitosan, 0.2g gelatin, 0.2g hydroxypropyl methylcellulose, dissolve in 19.4g 20wt% sodium hydrogen phosphate solution, prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan Sugar, 1% gelatin, 1% hydroxypropyl methylcellulose bone cement solidification solution. β-tricalcium phosphate, calcium dihydrogen phosphate monohydrate and modified hydroxyapatite were mixed in a ratio of 7:3:1, and the bone cement powder and curing liquid were mixed at a solid-liquid ratio of 1.5g / mL. The initial setting time measured by the standard ASTM C191 is 34 minutes. It has good injectability, and solid-liquid separation does not occur under a certain pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com