Synchronous biochemical advanced oxidation liquid waste treatment method and device

An advanced oxidation and waste liquid technology, which is applied in the field of sewage treatment, can solve the problems of hard-to-cultivate bacteria, high operating costs, and large investment, and achieve reduced initial investment and operating costs, low investment and operating costs, and easy operation and maintenance. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

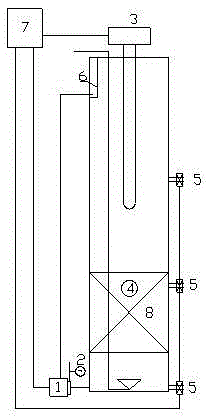

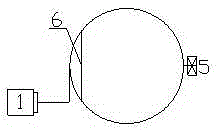

[0041] Such as figure 1 with figure 2 As shown, the synchronous biochemical advanced oxidation treatment waste liquid device of the present invention comprises a biological reaction tower and a dissolved air pump 1, and the dissolved air pump 1 communicates with the water suction pipe at the top of the biological reaction tower and the perforated water pipe at the bottom of the biological reaction tower, and the dissolved air pump 1 is used to The waste water is pumped from the sump into the bioreaction tower or the water in the tower is driven to circulate. The bioreaction tower has two layers of packing inside. filler such as figure 1 The carbon fiber filler 8 in the middle; the granular catalytic biological filler is placed in the middle of the biological reaction tower, the bottom of the suspended filler is 20cm away from the bottom of the biological reaction tower, the perforated water pipe is arranged at the bottom of the tower, the ultrasonic transducer horn is placed...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that the material of the granular catalytic biofiller layer in this embodiment is a natural mineral material loaded with transition metal oxides. The transition metal oxide is manganese metal oxide, and the natural mineral material is attapulgite. The suspended biological filler includes strip-shaped far-infrared biological filler and high softness filler.

[0054] The upper layer is granular catalytic biological packing accounting for 3% of the volume of the bioreaction tower, and the lower layer is hanging packing accounting for 35% of the volume of the biological reaction tower; the distance between the bottom of the hanging packing and the bottom of the bioreactor tower is 40cm; the ultrasonic power of the horn of the ultrasonic transducer is 0.3 KW, the frequency is 20KHz.

[0055] The biological reaction tower adopts sequential batch processing, and alternate aeration and static processes are set during e...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that: the suspended biological filler in this embodiment includes strip-shaped far-infrared biological filler and soft filler. The transition metal oxide is cobalt metal oxide, and the natural mineral material is expanded vermiculite.

[0059] The upper layer is granular catalytic biological packing accounting for 5% of the volume of the bioreaction tower, and the lower layer is hanging packing accounting for 40% of the volume of the biological reaction tower; the distance between the bottom of the hanging packing and the bottom of the bioreaction tower is 50cm; the ultrasonic power of the horn of the ultrasonic transducer is 0.5 KW, the frequency is 40KHz.

[0060] The biological reaction tower adopts sequential batch processing, and alternate aeration and static processes are set during each batch of processing. The treatment cycle is 1.5 days, and the ratio of aeration and static time during this period is 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com